Basic Info

Model NO.: CY-1700M/1800M

Customized: Customized

Structure: Rod

Type: Heating Element

Shape: Various

Diameter: 3, 6, 12mm, etc.

Transport Package: Wooden Box

Origin: Zhengzhou, China

Application: Industry, School, Lab

Certification: CE

Material: Mo

Temperature: 1000-1800c

Resistance: High Temperature

Trademark: CY

Specification: 6/12mm

HS Code: 85141090

Product Description

1800c U shape Silicon molybdenum rods / MoSi2 heating elements

Introduction

Molybdenum disilicide (MoSi2) heating element is a resistance generate-heating component made from MoSi2 or the basic material. It has unique effect for resisting oxidization in the high temperature. It is used to the highest temperature up to 1800 degrees during oxidizing atmosphere.

* Dia. 3,4,6,7,9,10,12,18,24

* Temp: 1000-1800 celsius degrees

* Used in the industries of metallurgy, magnetic materials, glass, ceramic refractory, crystal

electronic device,industrial furnace manufacture, lab furnace,Laboratory furnace,industry furnace,glass furnace,ceramic furnace etc..

features

a) Applied in the atmosphere of 1300C~1800C

b) High temperature resistance

c) Oxidizing resistance

d) A variety of shapes for your option, such as, rode type, U type, W type, U right angle type; also, supporting customized products.

application

a) Metallurgy

b) Steel making

c) Study and production of glass, ceramics, refractory matter, Crystal, electronic components, semiconductor materials, etc.

d) Furnace heating element

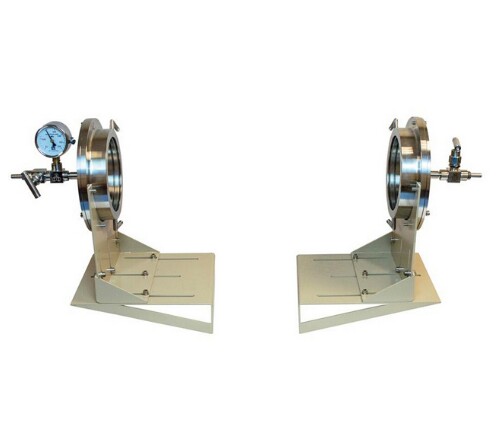

When you place order, please specify the data below:

a) d = the diameter of hot zone

b) c = the diameter of cold zone

c) Le = the length of hot zone

d) Lu = the length of cold zone

e) A = the distance between two terminals

Notes

a) MoSi2 should not be applied in 400C to 700C temperature range as the on this unfavorable conditions, the heating element in low temperature will result in oxidation damage of the component.

b) Silicon Molybdenum heating element is suitable for application in air and a neutral atmosphere. A reducing atmosphere such as hydrogen, etc will destroy the protective layer. The chlorine and

sulfur vapor has a direct damage to components.

MoSi2 furnace heater Standard sizes

M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24

MoSi2 furnace heater max specification

| Model | 1700C | 1800C | 1900C |

| d/c (mm) | 3/6 | 4/9 | 6/12 | 9/18 | 12/24 | 3/6 | 4/9 | 6/12 | 9/18 | 12/24 | 3/6 | 6/12 |

Max. Le

mm | 350 | 450 | 1400 | 1400 | 1700 | 350 | 450 | 1400 | 1400 | 1700 | 320.0 | 360.0 |

Max.Lu

mm | 300 | 450 | 1000 | 1000 | 1000 | 300 | 450 | 1000 | 1000 | 1000 | 320.0 | 360.0 |

Standard distance

D mm | 25 | 25 | 40/50 | 60 | 80 | 25 | 25 | 40/50 | 60 | 80 | 25 | 40/50 |

| a mm | 25 | 25 | 45 | 75 | 100 | 25 | 25 | 45 | 75 | 100 | 25 | 45 |

Factory

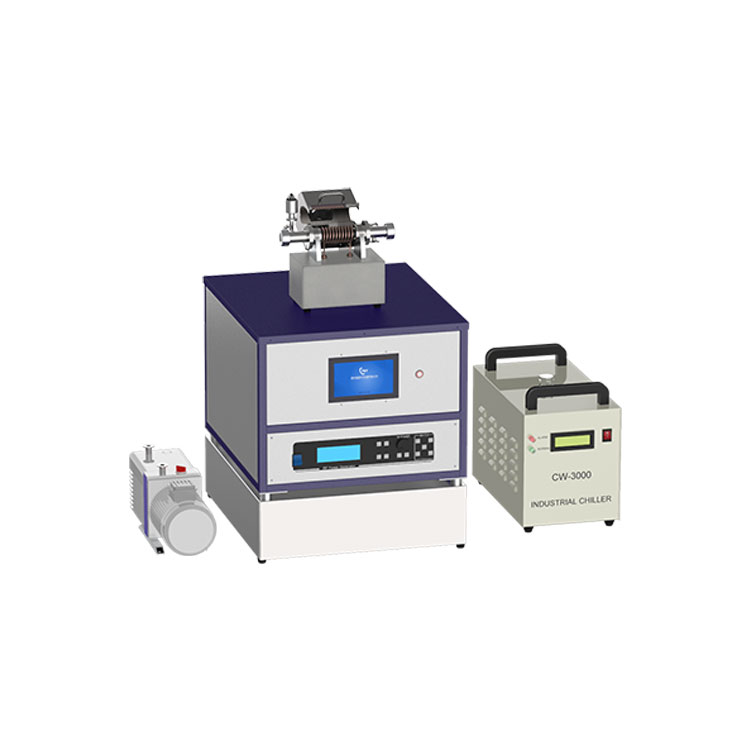

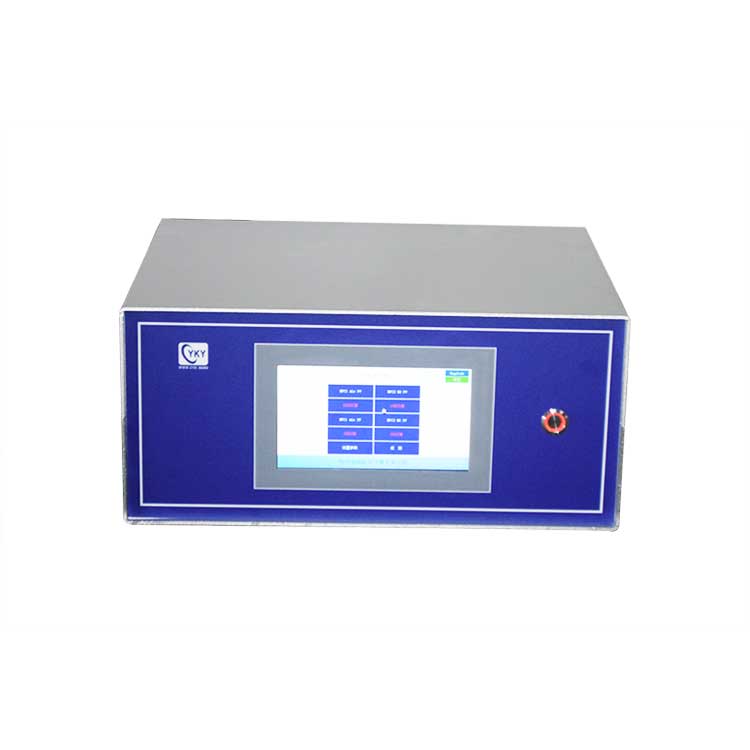

Zhengzhou CY Scientific Instrument Co., Ltd is mainly engaged in the research and development, design, manufacturing and sales of equipment used in scientific researches. Independence and innovation is the company's tenet.Our main products include: tube furnace, muffle furnace, plasma cleaner, vacuum furnace, atmosphere furnace,CVD system and customized lab equipment.Welcome you come to visit us.

Exhibition