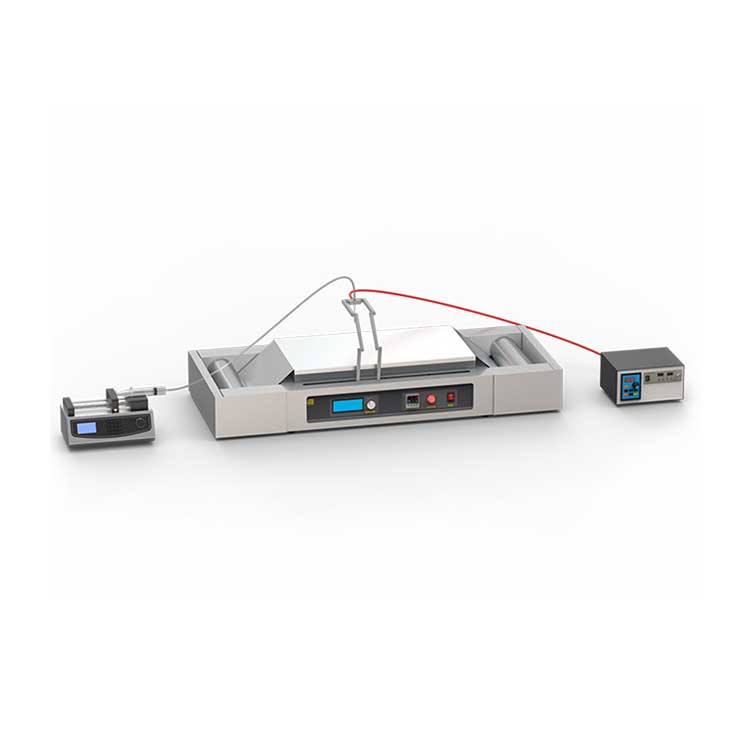

Lab nanofiber electrospinning machine comprises of a bipolar high voltage supply and a set of collectors for different applications. The instrument also equips with a unique rotary collector through which user will be able to spin the fiber into threads and collect it in spools. The diameter of the fiber depends on various parameters but mainly flow rate. In order to make fiber in to yarn, two syringe pumps, one with positively charged spinneret and the other with negatively charged spinneret, are targeted to a funnel shaped collector from where fiber yarns are formed and rolled into spool.

Lab nanofiber electrospinning machine is a system for producing the ultrafine fiber with the diameter of 20 - 1000 nm. The nanofiber has a high specific surface area, small diameter, and large porosity. There are more than 100 kinds of polymers could be used as raw materials, and also protein, collagen, organics (PEO, DNA, PAA, PLA, nylon, polyester, acryl resin, PVA, PS, PAN, peptide, cellulose).

Lab nanofiber electrospinning machine main features:

1. Cabin Heating: Upto 45°C using 1000 watt coil heater

2. The chamber is provided with Residual Charge Discharge Stick which is used for static removal

3. Safety switch provided to switch off H.V. Power supply when door is opened

4. LED cabin lighting and back light to view Needle tip and electrospin process

5. Exhaust fan is provied for solvent vaporization. It is also used for cooling down the equipment after spin process

6. Emergency stop is provided on the control panel to stop the equipment where there is any emergency

7. Graduation scale provided on the granite surface in X & Y direction which helps the end-user to achieve repetitive results by marketing the positions of syringe pumps, target and rim rotator

8. Software control of various features like mandrel rotating speed, duration, syringe pump flow rate, X, Y stage speed, etc.

9. Rotating mandrel targets of varying diameters, Y-stage target, and stationary plate target are provided with the system.

10. Coaxial spinneret: Our Nano fiber electrospinning unit equips Coaxial spinneret which helps to produce Hollow nanofibers and Core/Sheath nanofibers. This technology can also be used to combine different characteristic of each polymer into one fiber

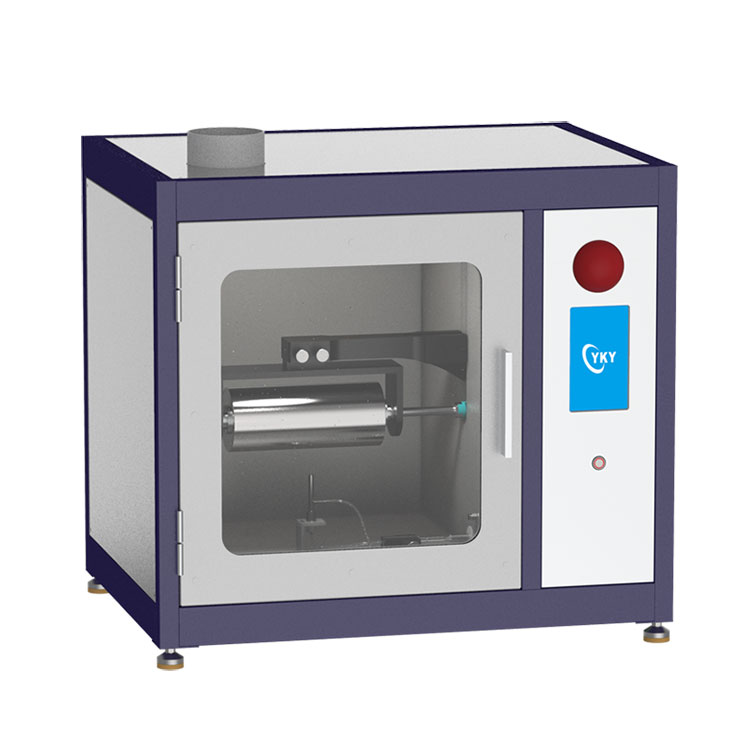

11. Stand-alone fume hood has features like exhaust fan, halogen lighting, and transparent door for monitoring electrospinning process

12. Built-in arc protection circuit

Lab nanofiber electrospinning machine specifications:

Input Power | • 208~240 VAC single phase (For 110 VAC, please order a 3000W transformer) • Max. power consumption: 1500 W |

High Voltage Power Supply

| • -15kV to +15kV Dual HV powersupply, 0.5 mA max current • Digital voltmeter and current meter • Electrostatic removal device-discharge stick is integrated to the fume hood • Constant current / constant voltage modes available • Built-in arc protection circuit. Normally for the electrospinning process, current < 5 μA. Please limit current < 20 μA to avoid high voltage arcing damage |

Dual-channel Syringe Pump

| • Dual-channel syringe pump with independent speed control allows syringes to eject solution at different rates. • Four syringe dispensing systems are included and controlled by the software. (Two syringes per group at the same pump rate) • Compatible with standard 2.5 to 60 mL glass syringes • Pumping rate: 1 uL/min - 35 mL/min for the included 20 mL syringe • Syringe holder made of insulating material to work under high voltage conditions • Programmable X motion profile to control the film coating characteristics • Moving resolution 1mm. • In standard package, only the standard high voltage alligator clip support is included. The 3-axis support and T shape dual 3-axis nozzle support are not included. Attention: Please use the glass syringes. Due to the safety concerns, do not use the disposal plastic syringes. |

Metal Funnel Collector and Yarn Spool

| • Metal funnel collector is a funnel shaped rotating mandrel where fiber yarns are formed and rolled into spool. A thin film web of nanofiber is first formed on a metal funnel collector and is drawn initially to a 3D cone shape. With the rotation of funnel collector, a twisted nanofiber yarn is drawn from the vertex of the cone. • Rotating speed: 300 to 4000rpm • Material: Aluminium • Diameter: 100mm • Yarn Spool is compact and modular motorized positioner for rolling the nanofiber yarn into spool. Stepper motor is used as electrical actuator. Yarn Spool is XY axis configurable. • Material: Acetal resin • Rotating speed: 1 to 100 rpm • Linear reciprocating movement: 50mm |

Mandrel Collector Plate Collector Y-Stage Collector | Three types of collectors are included as standard accessory

Mandrel collectors for electrospinning 7 sets with various size: 200 mm length x 100, 75, 25, 12, 6, 2 mm Dia. Actuator: Microprocessor controlled BLDC motor with hall sensor feedback Speed: 400 to 3500 rpm adjustable with stability: +/-1% PC-based control of speed and duration Rotating mandrels can be used as a target to get an aligned continuous mesh of nanofiber Plate collector for nanofiber-collecting 320 mm×100 mm×2 mm thick stainless steel plate with grounding Y-stage collector for flat film coating Stage dimensions 250 mm×175 mm×2 mm thick Plate material: Stainless steel Programmable Y motion profile to control the film coating characteristics PC-based control of speed, movement profile, and duration Moving Resolution 1mm |

Lamp Heater | • Halogen lamp heater with thermal couple and digital temperature controller are integrated into the fume hood for environmental heating up to 40 ºC • Max power: 1000 W |

Fume Hood | • Stand-alone unit with built-in power supply and features like heater, lighting and exhaust fan • Transparent glass windows on front and both sides for easy monitoring of the electrospinning process • Footprint: 1000 mm×800 mm×1672 mm • Construction material: Stainless Steel, Aluminum, and Glass. Fume hood is epoxy coated for electrical insulation • Front door interlock for turning off high voltage output when the door is accidentally opened during the electrospinning process. Hazard lamp is installed on top of the fume hood to indicate that high voltage output is on. • Exhaust fan with 3.8'' Dia. venting port is installed on the top of the hood which can be connected to an exhaust outlet at the customer's facility • The volumetric flow of Exhaust fan is 117 CFM (cubic foot/minute [ft3/min]). |

Software | • The system controller box is connected to laptop or Surface Pro via RS232 port and USB adapter • Centralized software control of syringe pump, X-stage, Y-stage, mandrel collector, and almost all of the electrospinning parameters • All of the process parameters can be saved as a user process and retrieved later for analysis or re-run • One brand new laptop computer or one Microsoft Surface Pro with pre-installed software is included. |

Humidity Monitor and Control | Humidity monitor is integrated into the fume hood for monitoring the humidity level (RH%) ranging from 2%-95%. |

Warranty | One-year limited warranty with lifetime support (demo before purchase available) |

Compliance | CE certified |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.