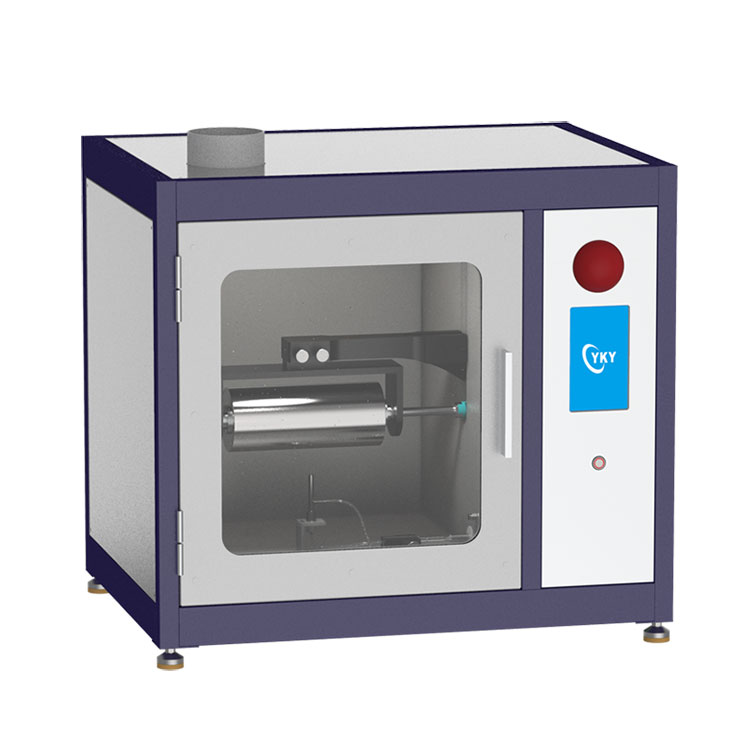

This high-voltage electrospinning machine is for preparing ultra-fine fibers with the diameter of 20-1000nm by using a polymer solution or molten liquid in a strong electric field. The nanofiber has a high specific surface area, small diameter, and large porosity. There are more than 100 kinds of polymers could be used as raw materials, and also protein, collagen, organics (PEO, DNA, PAA, PLA, nylon, polyester, acryl resin, PVA, PS, PAN, peptide, cellulose).

Main parts: liquid supply device, high voltage power supply, spinning nozzle, collecting device

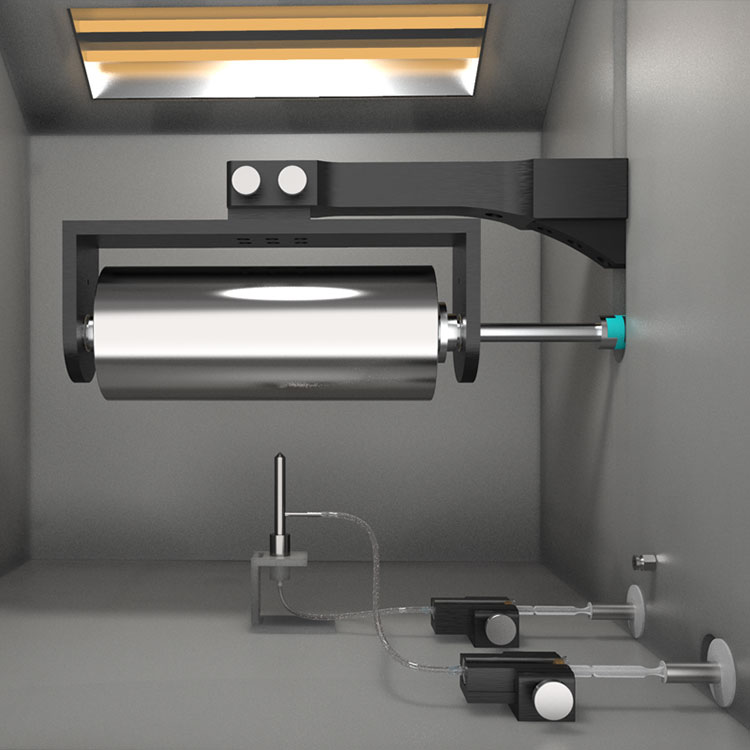

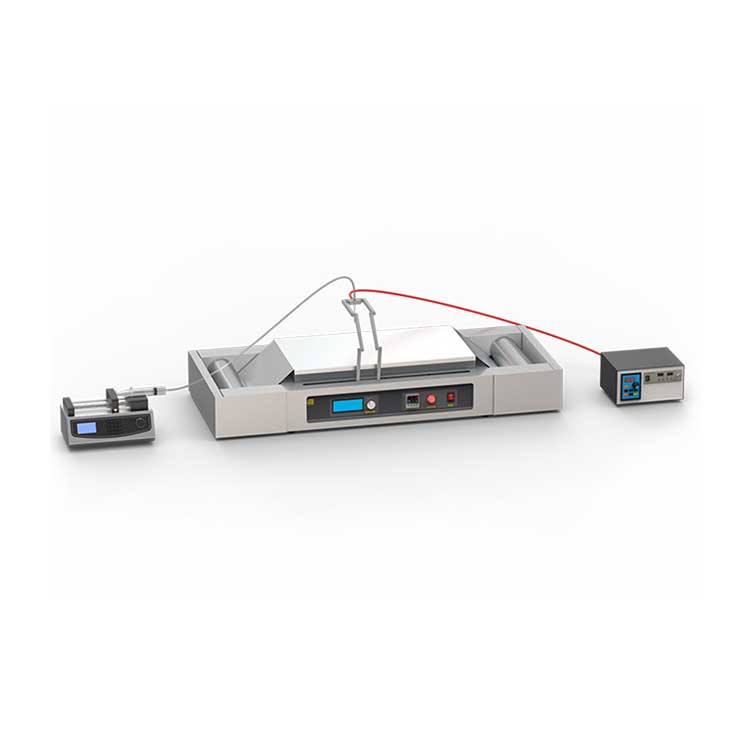

1. Liquid supply device: uses two professional scientific research syringe pumps, can provide liquid with continuously stable flow, and the liquid supply speed is adjustable to meet the needs of different spinning solutions.

2. High voltage power supply: can provide a stable electric field for a long time, electric field strength standard 0~30KV.

3. Spinning nozzle: Coaxial nozzle, which is composed of two inner and outer layers of two needles with different diameters. It can be used to make hollow-structured nanofibers, shell-core structured nanofibers, micron fibers, etc. Using coaxial spray technology, polymers with different properties can be combined to make nanofibers with special properties. In addition, some polymers with poor spinning performance can also be prepared into special nanofibers by coaxial spray technology. In this case, the polymer with poor spinnability should be used in the outer layer of the coaxial nozzle, and the polymer with good spinning performance as the inner structure. Besides, the support of spinning nozzle is adjustable for obtaining the best spinning distance and non-woven fabrics with different widths, which can perform automatic reciprocating motion parallel to the collector, effectively improve the uniformity.

4. Collecting device: standard configuration is one drum collector. Other plate collectors are optional.

Technical parameters:

Input Power supply | AC220V 50Hz |

High voltage power supply | Output voltage | 0~30KV |

Max. current | 1mA |

Max. Power | 30W |

Temperature Coefficient (Temperature Drift) | 0.1%/℃ |

Stability | 0.1%/h (after 30 minutes preheating time) |

Load Regulation | 0.5% |

Adjustment mode | Potentiometer adjustment |

Heater | Heating method | Infrared heating tube |

Working temperature | ≤ 60℃ |

Max. heating power | 1 KW |

Syringe pump | Quantity | 2 sets |

Channel for each pump | 1 |

Capacity | 2.5ml-60ml |

Flow range | 2.779 μl/min~72.24 ml/min |

Spinning nozzle | Coaxial nozzle | Used to make hollow-structured nanofibers, shell-core structured nanofibers, micron fibers, etc. |

Collectors | Drum collector | Size: 200mm* Φ100mm Driver: brushless motor Rotating speed: 300-4000rpm Can be used for electrospinning |

Humidity Monitor | A humidity monitor is for monitoring the humidity level (RH%) ranging from 2% - 95% |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.