A powder magnetron sputtering coating machine is a device used to deposit thin films on the surface of substrates by converting powder-form target materials into a thin film using magnetron sputtering technology. Below is a detailed explanation of its working principle and applications.

The working principle of a powder magnetron sputtering coating machine is primarily based on magnetron sputtering technology. The specific steps are as follows:

Working Principle

Target Preparation:

The target material exists in powder form, typically made of metals, alloys, ceramics, or other materials. These powder targets are loaded into the target holder as the sputtering source.

Vacuum Environment:

The coating process is carried out in a vacuum chamber to reduce the interference of gas molecules with the sputtered particles, ensuring the stability of the deposition process and the quality of the thin film.

Plasma Generation:

An inert gas (such as argon) is introduced into the vacuum chamber, and a high-voltage electric field is applied to generate plasma. High-energy ions (such as argon ions) in the plasma are accelerated by the electric field and bombard the surface of the target material.

Sputtering Process:

High-energy argon ions bombard the surface of the powder target, causing atoms or molecules from the target material to be ejected. These sputtered particles move freely in the vacuum and eventually deposit on the substrate surface, forming a uniform thin film.

Magnetron Enhancement:

The magnetron device generates a magnetic field that works in conjunction with the electric field, causing electrons to form a circular motion near the target surface. This significantly increases the ion bombardment density on the target surface, thereby improving the sputtering efficiency.

Film Formation:

The sputtered target particles deposit on the substrate surface, gradually forming the desired thin film. By controlling the sputtering time, the type, and concentration of the target powder, the thickness and composition of the film can be adjusted.

Powder magnetron sputtering coating machines are widely used in the following fields:

Semiconductor Manufacturing:

Used for depositing various functional thin films, such as conductive layers, insulating layers, and barrier layers, which are crucial steps in semiconductor device manufacturing.

Optical Devices:

Applied in coating optical components to form anti-reflective layers, filtering layers, or reflective layers, thereby improving optical performance.

Protective Coatings:

Depositing wear-resistant coatings on tools or mechanical parts, increasing surface hardness and corrosion resistance, thus extending service life.

Decorative Coatings:

Used for depositing decorative coatings, changing the color, gloss, or texture of objects, and widely applied in jewelry, watches, and other fields.

Energy Sector:

Utilized in manufacturing transparent conductive oxide (such as ITO) films for solar cells, as well as depositing functional layers in energy storage devices.

Biomedical Devices:

Applied in the functionalization of biomedical device surfaces, such as depositing antibacterial coatings or biocompatible coatings on implants.

Advantages

The powder magnetron sputtering coating machine is advantageous due to its compatibility with various materials and its ability to control the uniformity and composition of the thin films, making it an indispensable tool in industrial and research fields.

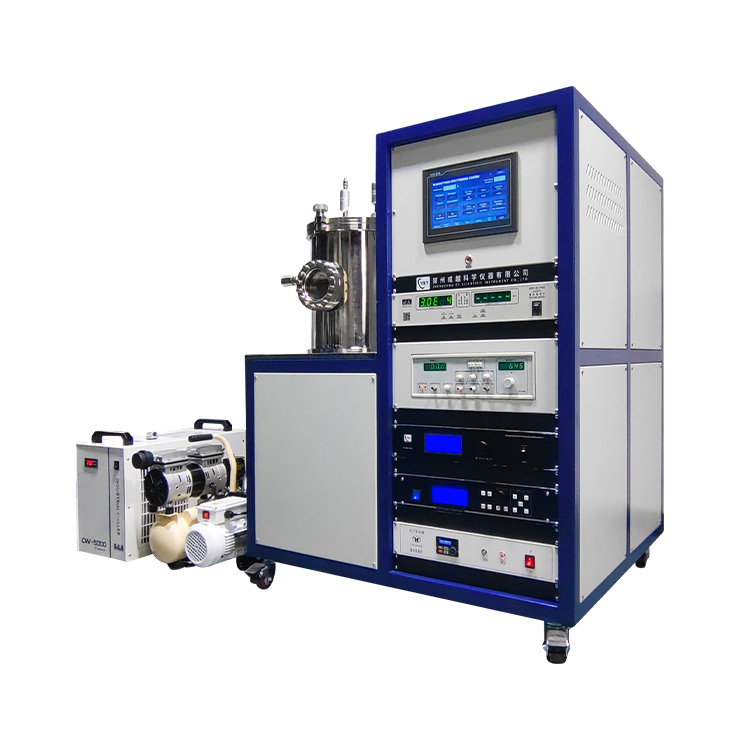

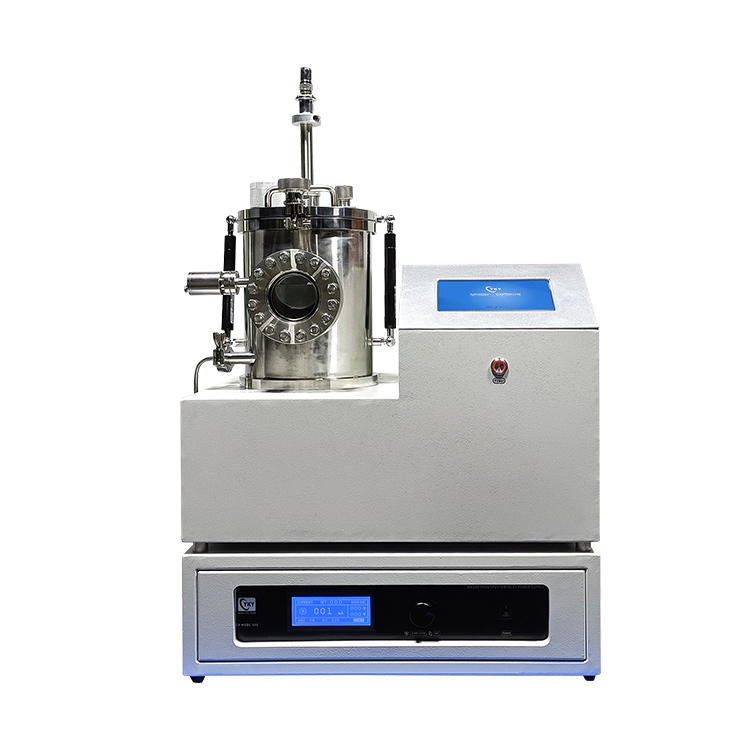

Technical Parameters of Magnetron Sputtering Coating Machine:

Product name | powder magnetron sputtering coating machine |

Product model | CY-MSH325-II-DCRF-SS-ZD |

Power supply voltage | AC220V,50Hz |

Complete power | 6KW |

System vacuum | ≦5×10-4Pa |

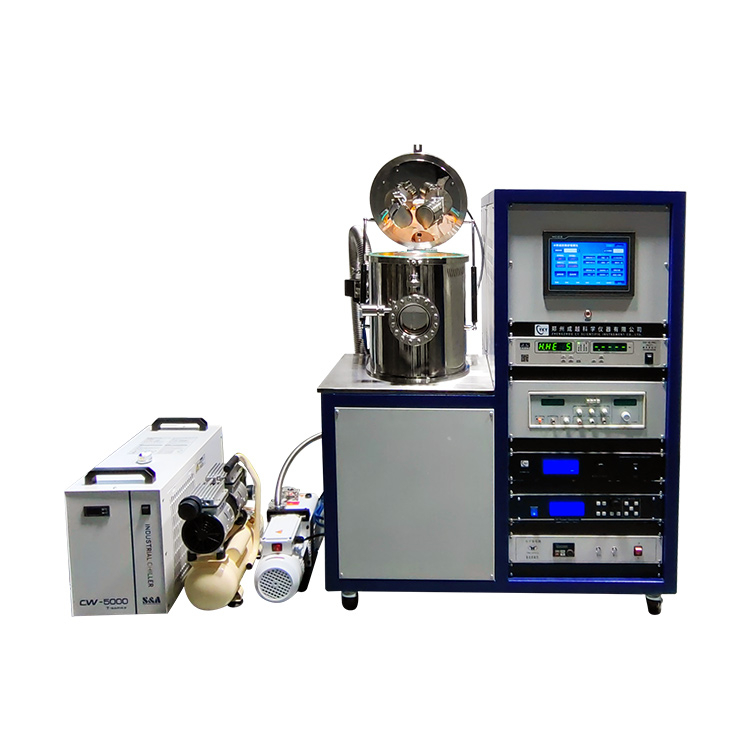

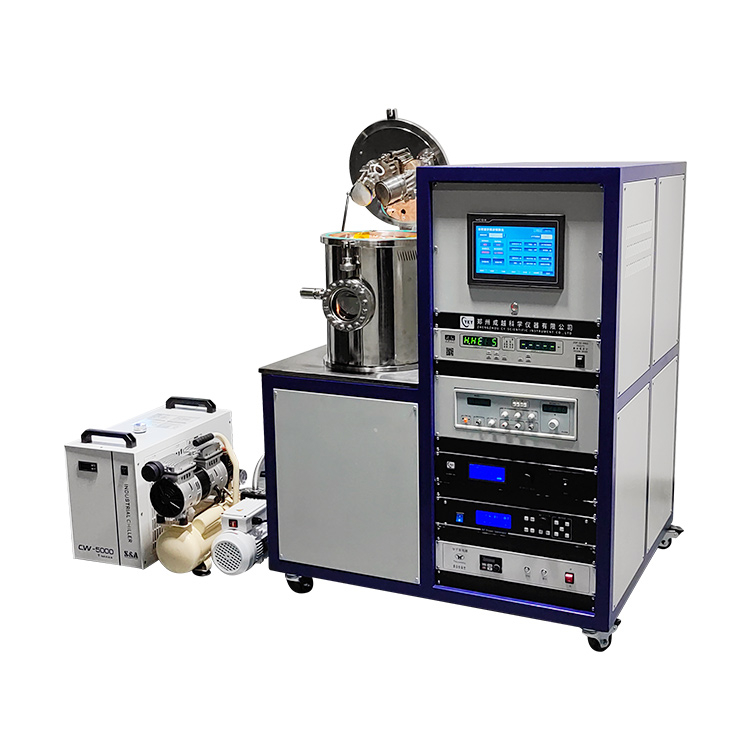

Sample stage | Dimensions | φ150mm Vibration frequency 20Hz-20KHz |

Magnetron Sputtering Target | Target size | Diameter Φ50.8mm, thickness ≦3mm |

Cooling mode | Circulating water cooling |

Water flow size | Not less than 10L/Min |

Quantity | 2 |

Vacuum chamber | Cavity size | Diameter φ325mm |

Cavity material | SUU304 stainless steel |

Observation window | Diameter φ100mm |

Opening method | Top opening |

Gas control | 1 mass flow meter is used to control Ar flow, with a range of 200SCCM |

Vacuum system | Equipped with 1 molecular pump system, gas pumping speed 600L/S |

Film thickness measurement | Optional quartz crystal film thickness meter, resolution 0.10 Å |

Sputtering power supply | Equipped with DC power supply, power 500W RF power supply 500W |

Control system | CYKY self-developed professional control system |

Equipment dimensions | 570mm×1040mm×1700mm |

Equipment weight | 350kg |