A spin coater is an instrument used to prepare thin films and is widely used in materials science, physics, chemistry and other fields. Its main working principle is to use centrifugal force to evenly coat the glue dripped on the substrate on a high-speed rotating substrate, thereby preparing a uniform, dense, and thickness-adjustable thin film. The spin coater is considered to be one of the important tools for preparing high-quality samples.

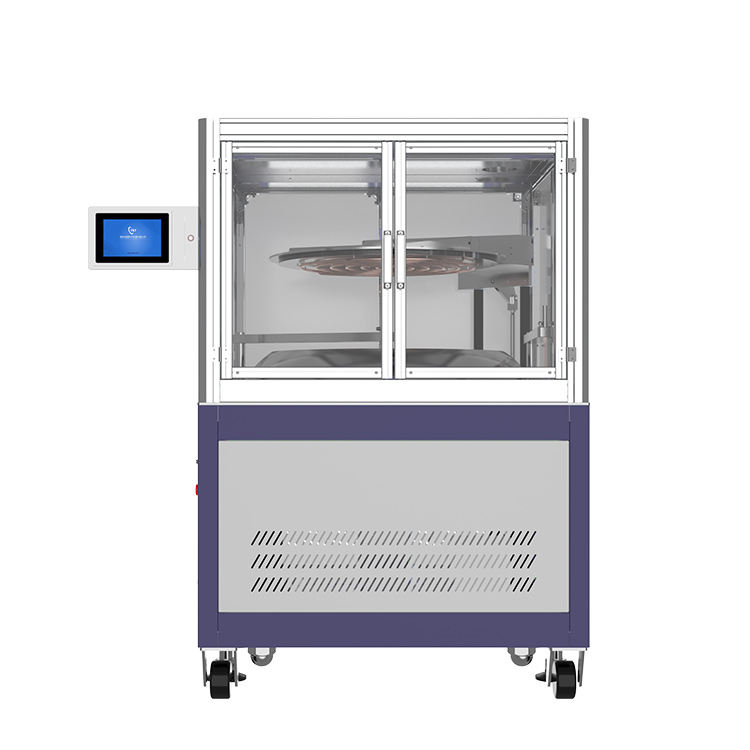

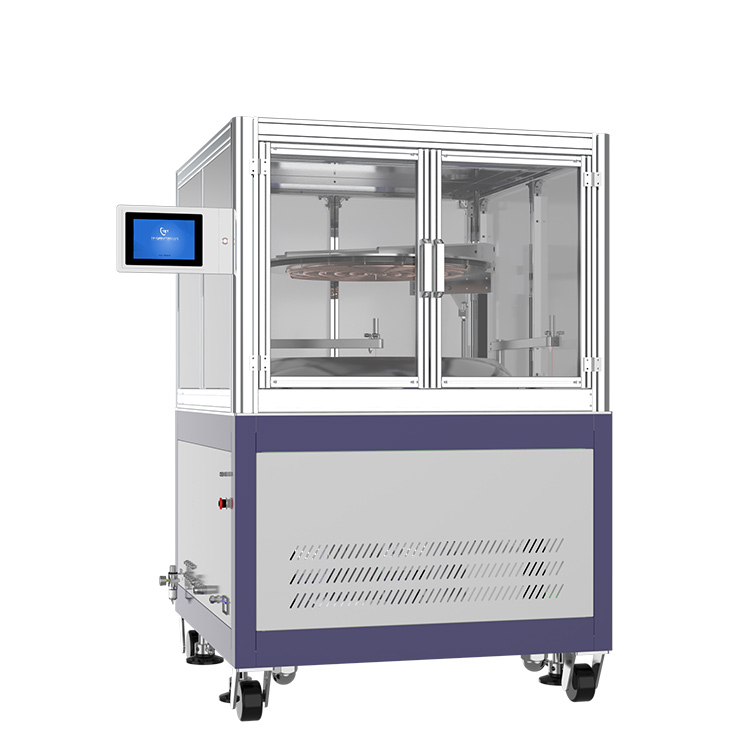

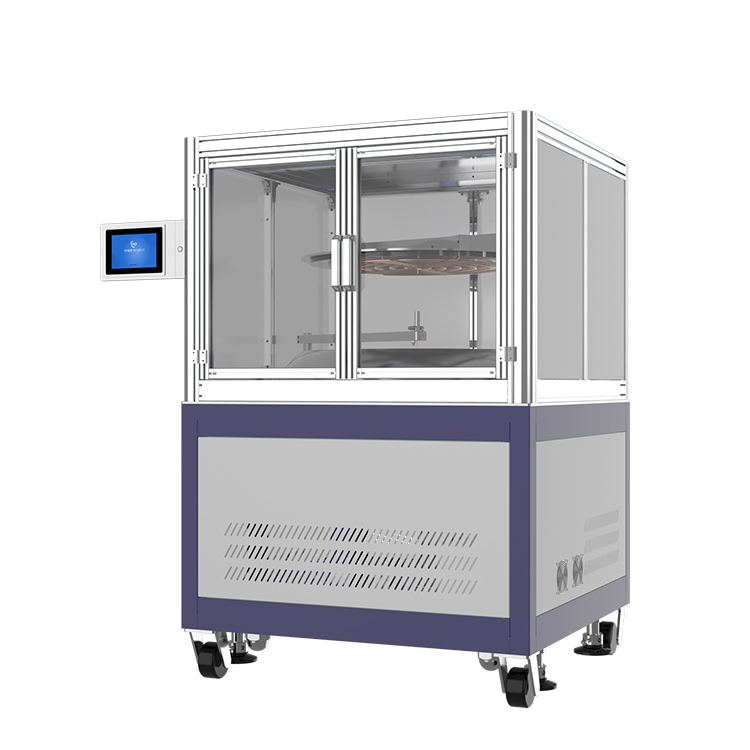

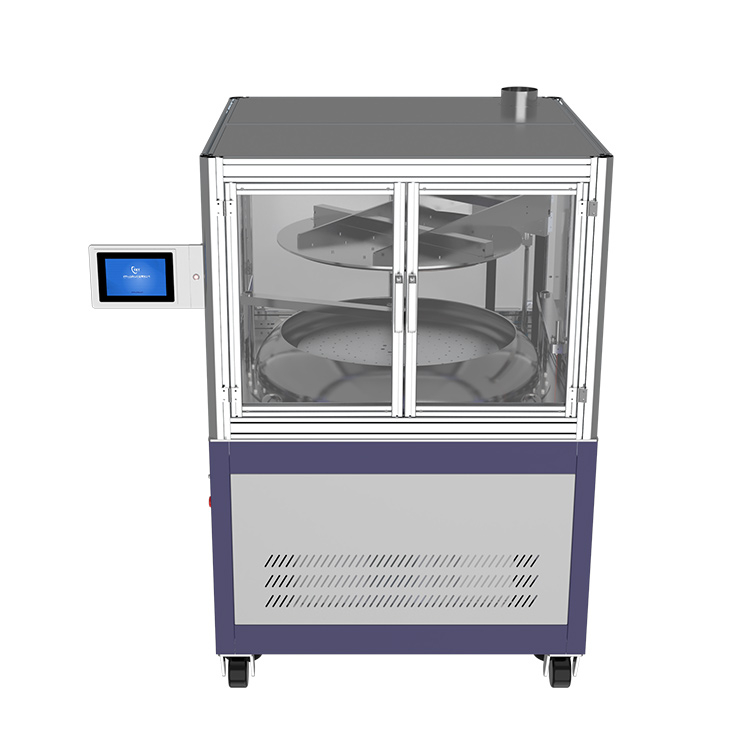

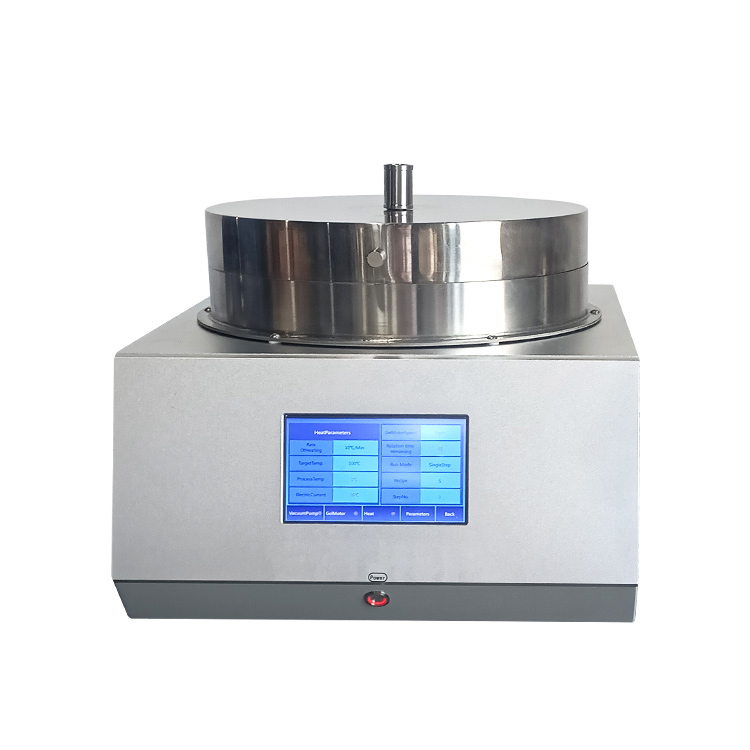

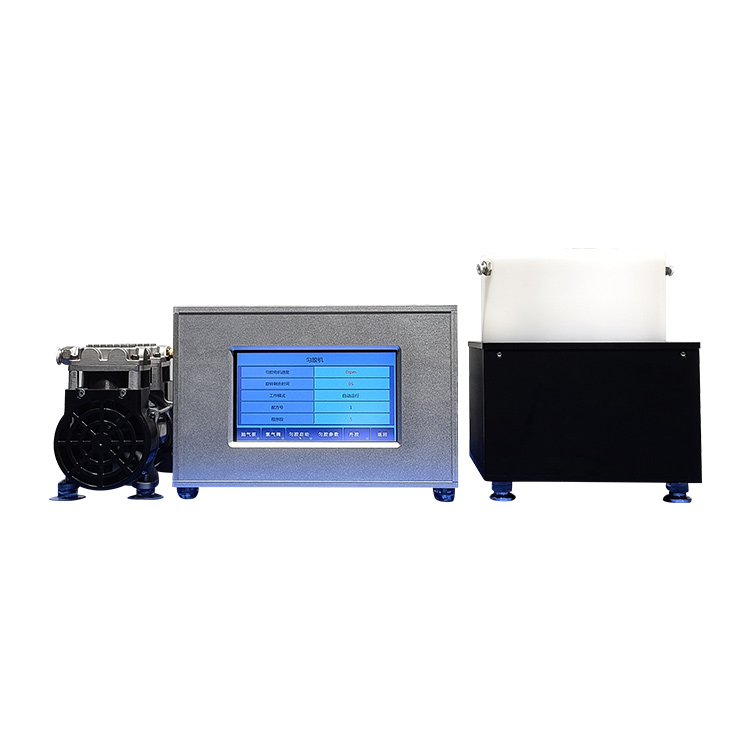

The glue spreader is mainly composed of a base, a rotating disk, a transmission device, an exhaust device, an annotation system, and a digital display temperature controller. The preparation process can be divided into the following steps: placing the solution on the rotating disk; starting the rotating disk for centrifugal action; controlling the rotation speed and time to form a film of the desired thickness; and finally using the exhaust device to remove the remaining glue on the coating surface.

When in use, the glue spreader needs to prepare a certain amount of solution or mixture of the required materials, usually using an organic solvent or water as a diluent, and adding a surfactant to improve the viscosity and surface tension. The formula of the mixture should be determined according to the chemical properties and thickness of the required film.

In addition, the spin coater uses advanced precision motors, and its speed can reach very high, such as 10,000 rpm, which effectively ensures the uniformity of film formation. At the same time, it may be controlled by a touch screen, and the coating curve can be preset, which greatly simplifies the use process and reduces the learning cost.

Please note that different spin coaters may have different characteristics and functions, so when selecting and using them, it is recommended to refer to the instructions of the relevant products or consult professionals.

The main purpose of the spin coater is to evenly coat liquid or colloidal materials on substrates such as silicon wafers, crystals, quartz, and ceramics to form a thin film. This equipment is widely used in various fields, including but not limited to photoresist spin coating, biological culture medium preparation, and sol-gel method for making polymer films.

Specifically, the spin coater rotates the substrate at high speed and uses centrifugal force to evenly distribute the glue on the surface of the substrate to form a uniform and dense film. The thickness and uniformity of this film can be adjusted by controlling the rotation speed and time to meet the needs of different applications.

In photoresist spin coating, the spin coater is used to prepare photoresist films on silicon wafers or other substrates, which is a key step in the manufacture of semiconductor devices and integrated circuits. In the production of biological culture medium, the coating machine is used to prepare uniform biological culture medium film for research such as cell culture and tissue engineering. In addition, the spin coater also plays an important role in the production of polymer films by the sol-gel method.

In general, the spin coater is widely used in many fields such as materials science, semiconductor manufacturing, biology, etc., providing important technical support for scientific research and production.

Technical parameters of the spin coater:

Product name | 1000MM spin coater |

Product model | CY-SPC40-T-SS |

Supply voltage | AC380V 50H |

Rated power | 15KW |

Speed | max1500rpm |

Cavity size | 1000MM |

Cavity material | Stainless steel 304 |

Tray size | 780mm |

Tray material | Aluminum alloy |

Control system | Touch screen LCD screen, single-step or multi-step glue spreading operation |

Glue baking system | Baking temperature max 200℃ |

Glue dripping system | Multi-point glue dripping, 3-5 drip nozzles, automatic injection |

Dimensions | 1400*1400*2000 |

Weight | 1.5T |