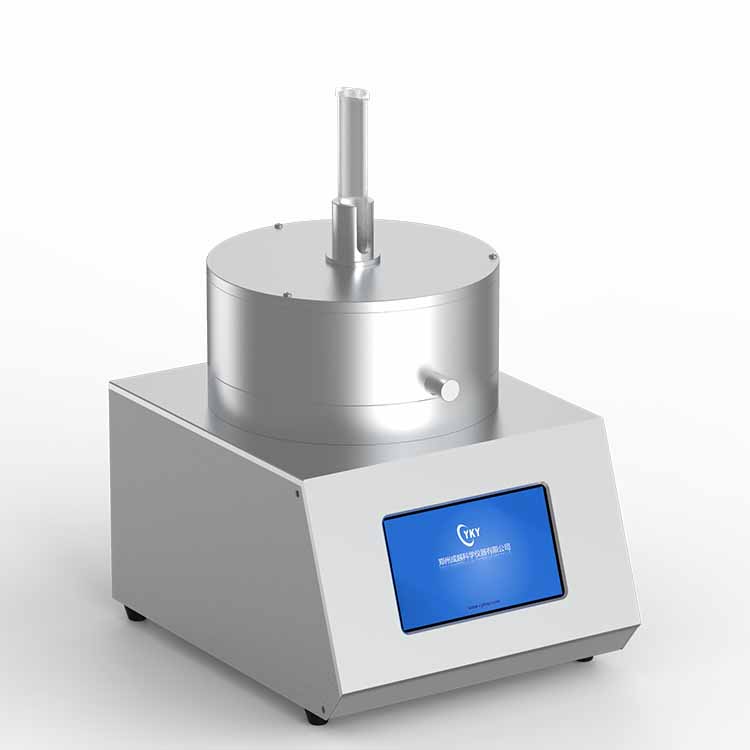

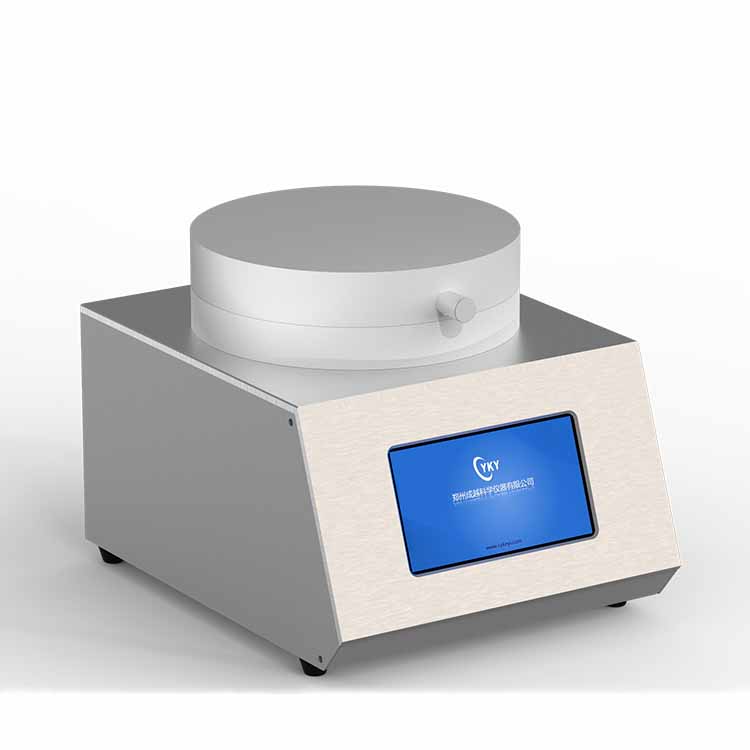

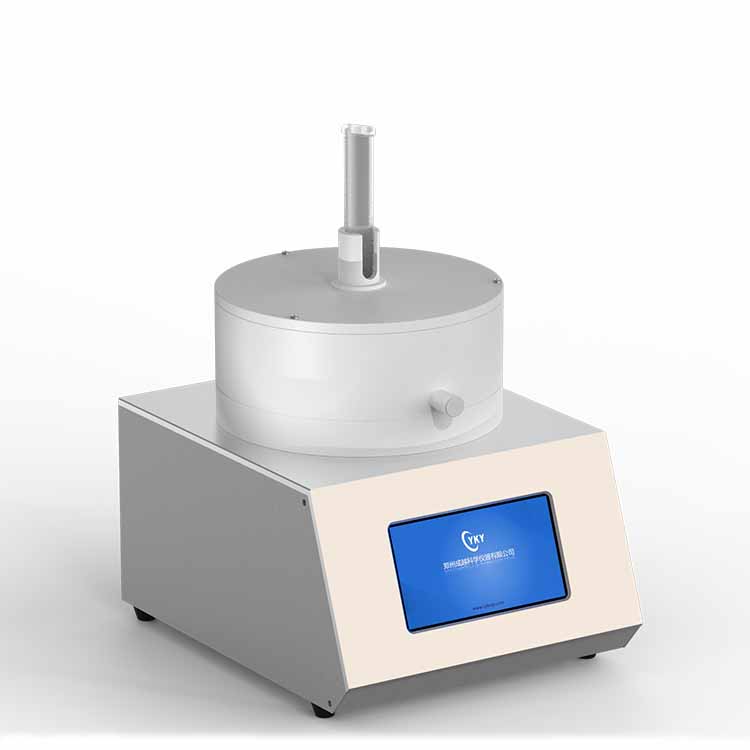

The lab Compact Vacuum Spin Coater is suitable for surface coating processes such as semiconductor, silicon wafer, wafer, substrate, conductive glass and plate making. It can be used in production, scientific research and teaching in industrial and mining enterprises, scientific research, education and other units.

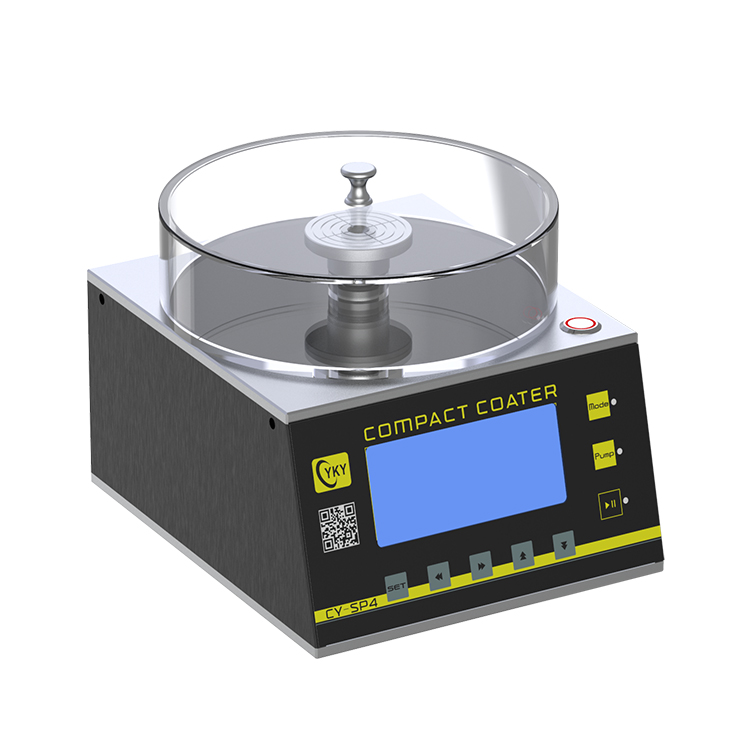

VTC-100A is CE certified compact spin coater with vacuum chucks designed for easy and quick coating via sol-gel for wafers up to 4". The spinning speed is variable from 500-8000 rpm with two programmable segments. The package comes included with complete accessories for immediate use

lab Compact Vacuum Spin Coater Main Features:

1) Desktop type homogenizer, coating film thickness range: 100nm~100um;

2) can be used for photoresist (PR), polyimide , metal organic , dopant, silicon film , and most organic solutions, aqueous solutions;

3) Compact design, user editing, control, storage, and removal of the glue application program, easy to operate;

4) The acceleration and deceleration rates are automatically calculated based on the set time/speed (Ramp Time/RPM value);

5) The user edits, controls, stores, and removes the glue application program through the front panel display and buttons of the glue machine, and performs experimental operations.

lab Compact Vacuum Spin Coater Specifications

Spin Speed & Time: Digital control panel with TWO programmable segments for different spin times and speeds

Spinning speed: 500 - 8000 RPM

Spinnning Time: 1 - 60s

Input Power:110VAC or 220VAC please select the voltage in options bar (10A fuse)110VAC)

Motor Power: 24V DC motor with 150W Max.24V

Product Dimensions13''(L) x 10''(W) x 8.5''(H)

Net Weight:15 kg (33 lbs)

Compliance:CE Certified

Shipping Dimensions:40"(L) x 28"(W) x 24"(H)

Shipping Weight:46 kg (100 lbs)

Warnings:

Do not overflush the water bowl/base with any kinds of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use fabric cloth to wipe out the residues remain in the bow/base.

If necessary, turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation.

For more details about the cleaning procedure, please review the cleaning instruction for the spin coaters.

lab vacuum spin coater Product Detail

Design principle:

Aluminum casting case to keep spinning stable

Liquid disk made of Polypropylene (PP) to resist most of the corrosive solutions

Drainage outlet and vacuum pump connector are on back panel,One filter is included in standard package. It is used to connect the coater for preventing waste water flowing into the pump

The spin coater can be used in glovebox with Ar g or N2 gas, but pump must be put in outside glove box via a feedthrogh).

20mL syringe is used to contain the coating material,The syringe holder height can be adjusted and rotated freely along the support rod.

lab vacuum spin coater Advantage:

Precise speed control and repeatability (less than 0.2rpm)

Precise temperature control (temperature uniformity: 0.3%)

Repeatability and stability (motor spin coating speed stability error < ±1%)

Flexible and versatile and comprehensive options (automatic dispensing, back cleaning, development, edge removal, etc.)

Economical and practical good value for money