Spin coater, also known as spin coater or spin coater, is an experimental device for preparing thin films. It is mainly used to evenly coat liquid samples on substrates to form a uniform thin film. The following is a detailed explanation of the spin coater:

Spin coater is a coating device that uses the centrifugal force generated by rotation for coating. It is able to produce a thin and uniform coating on a flat and smooth target.

Working principle:

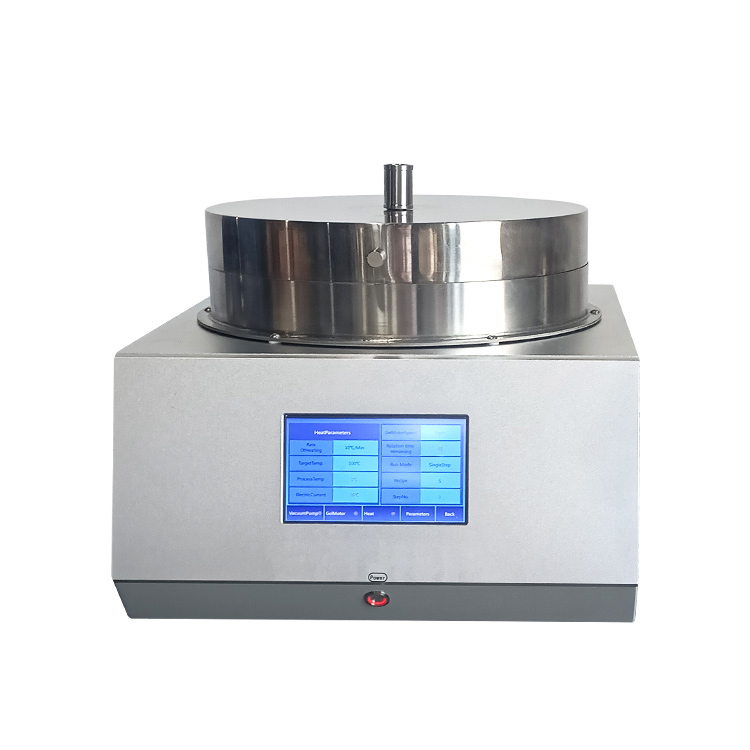

The working principle of the spin coater is to add the liquid sample to the surface of the rotating substrate, and the sample is evenly distributed on the surface of the substrate through centrifugal force, and finally a uniform thin film is formed. The spin coater is usually composed of a rotating table, a control system, a nozzle, and a motor. During operation, the user needs to pour the sample on the substrate, place the substrate on the rotating table, and then control the rotation speed and rotation time so that the sample is evenly coated on the substrate surface while rotating.

Application field:

Spin coaters are widely used in many fields, including anti-corrosion coating on semiconductor wafers, coating of optical media, coating primers or photochromic solutions on lenses, etc. At the same time, it is also commonly used in research in the fields of materials science and chemistry, such as the preparation of thin films, coating, electroplating and other experiments that require uniform coverage.

The spin coater can coat liquid or colloidal materials on substrates such as silicon wafers, crystals, quartz, ceramics, etc. to form a thin film. It is mainly used for photoresist spin coating, biological medium preparation, sol-gel method for preparing polymer films, etc.

Precautions for use:

When using a spin coater, it is necessary to pay attention to the selection of a suitable spin coating liquid, which is the key to spin coating technology. In addition, it is also necessary to pay attention to controlling the rotation speed and rotation time to ensure the quality and uniformity of the coating.

Main components:

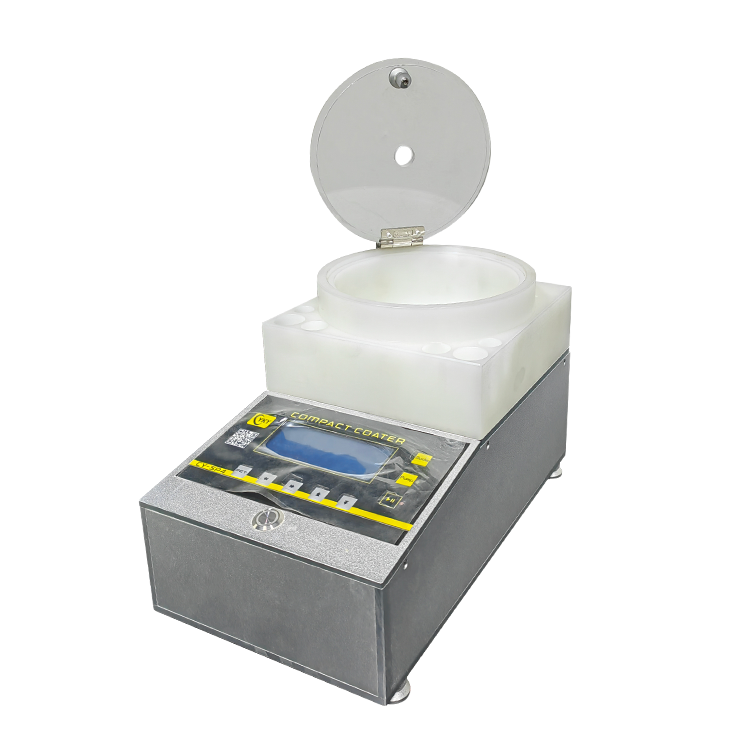

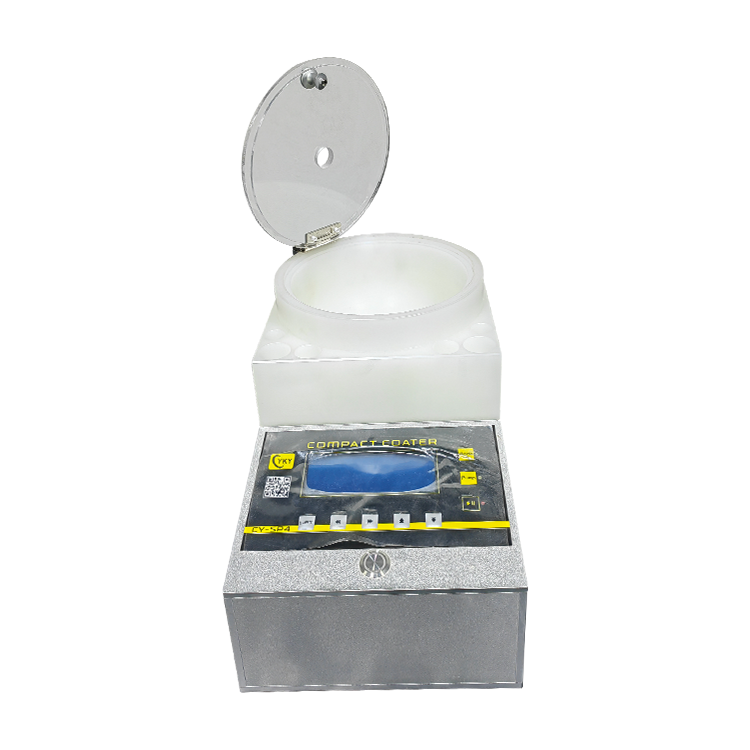

The main components of the spin coater include a base, a rotating table, a fixture, etc. These parts work together to ensure that the spin coater can work stably and accurately.

Technical parameters:

Product name | PP Chamber Spin Coater |

Product model | CY-SPC8-PP-DZ |

Power supply voltage | AC220V,50Hz |

Speed | 0~10000rpm |

Acceleration | 100~5000rpm/s |

Speed resolution | 1rpm |

Single-step time | 3000s |

Cavity size | 170mm |

Cavity material | PP Chamber |

Suction cup | No suction cup, need to customize mechanical chuck |

Glue dripping method | Customer design mechanical hand glue dripping |

Vacuum interface | Exhaust gas, waste liquid extraction interface |

Control method | Provide communication interface connected to PC |

Complete machine size | Chassis part requires separation from cavity |

Complete machine weight | 12kg |