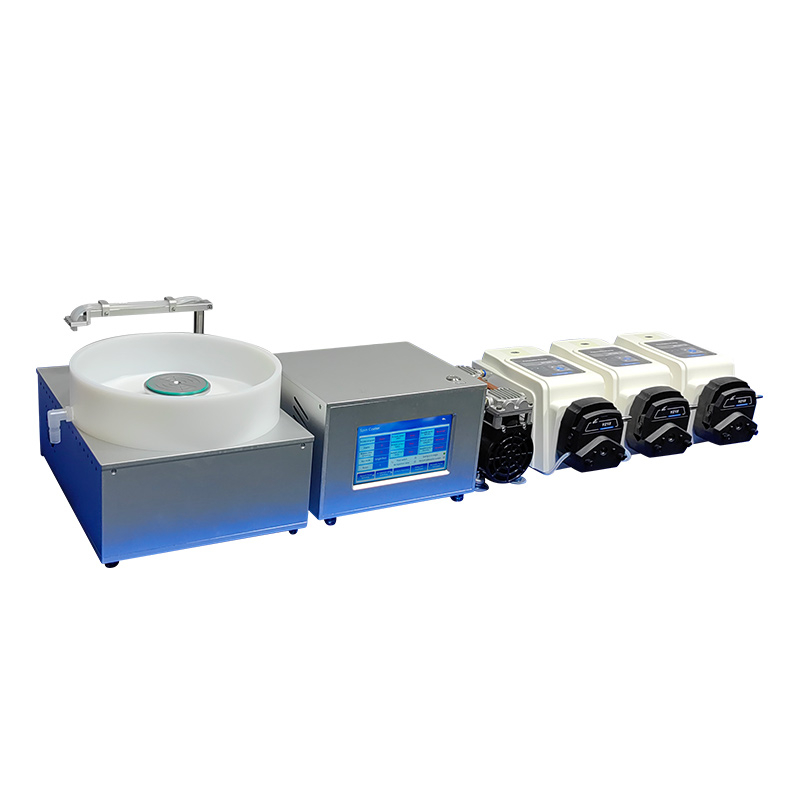

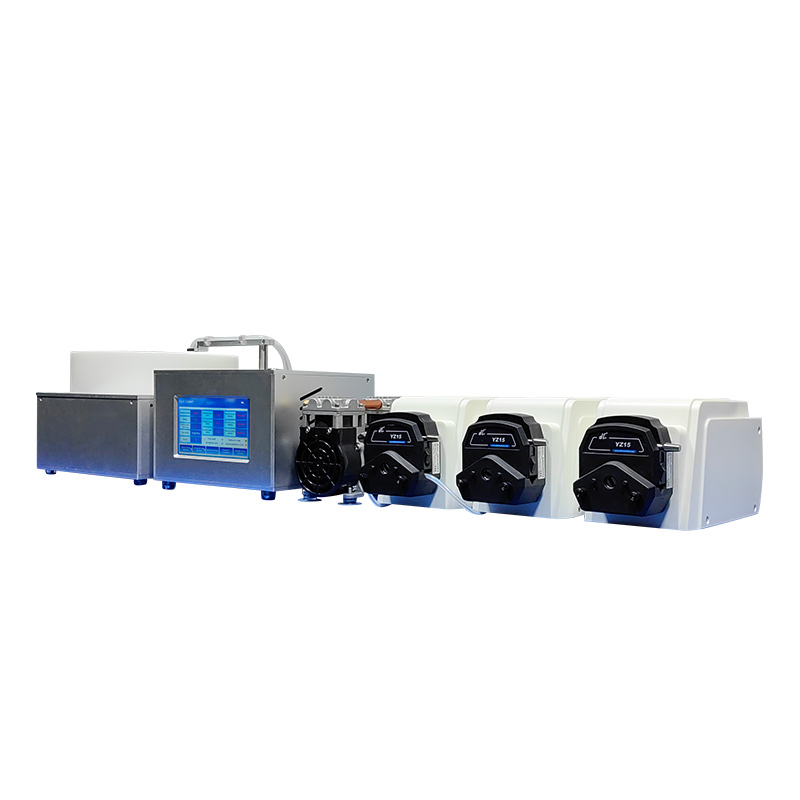

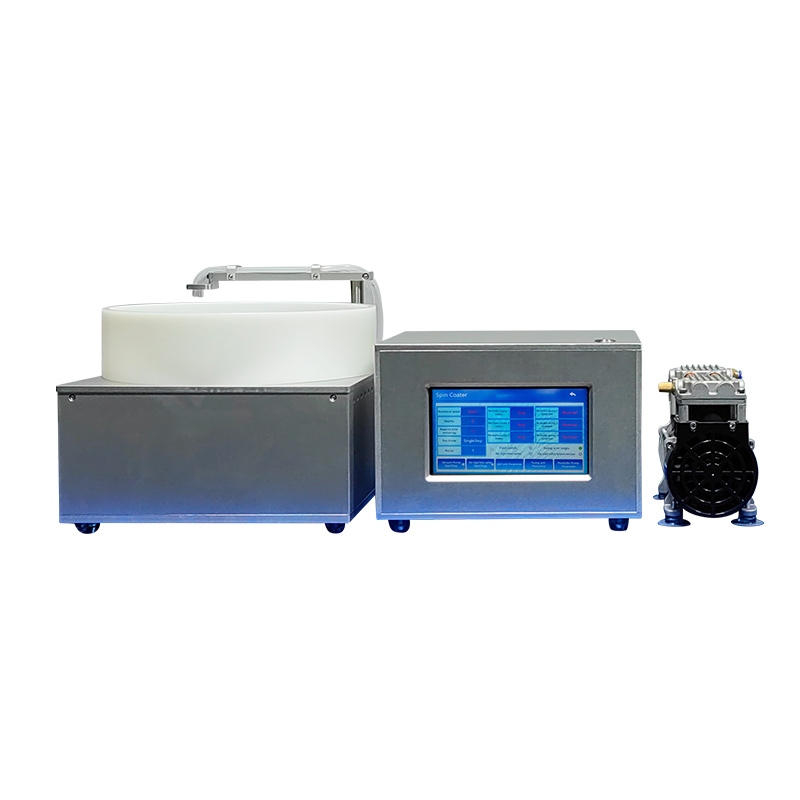

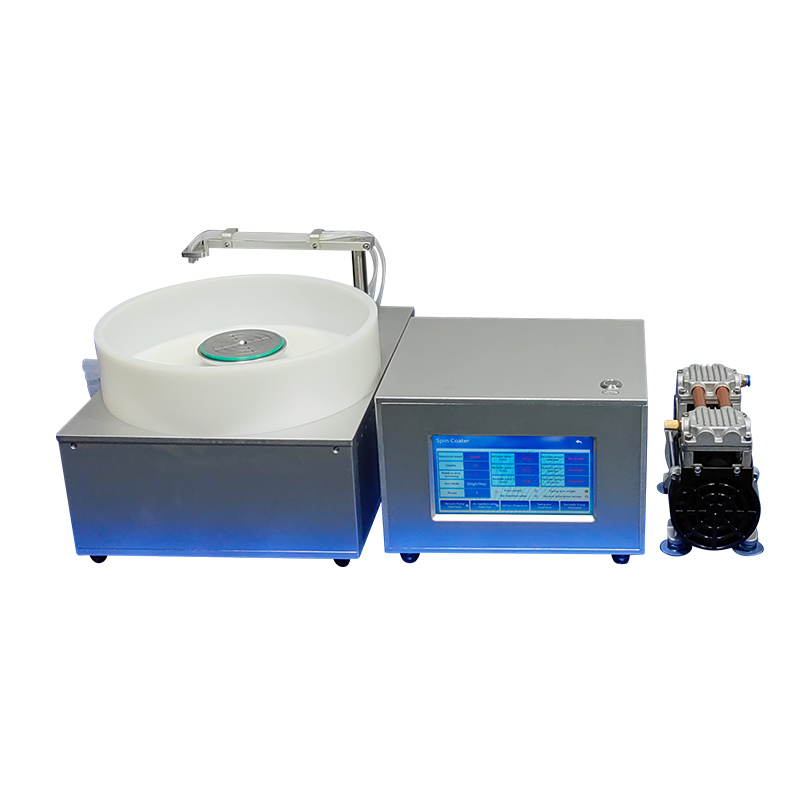

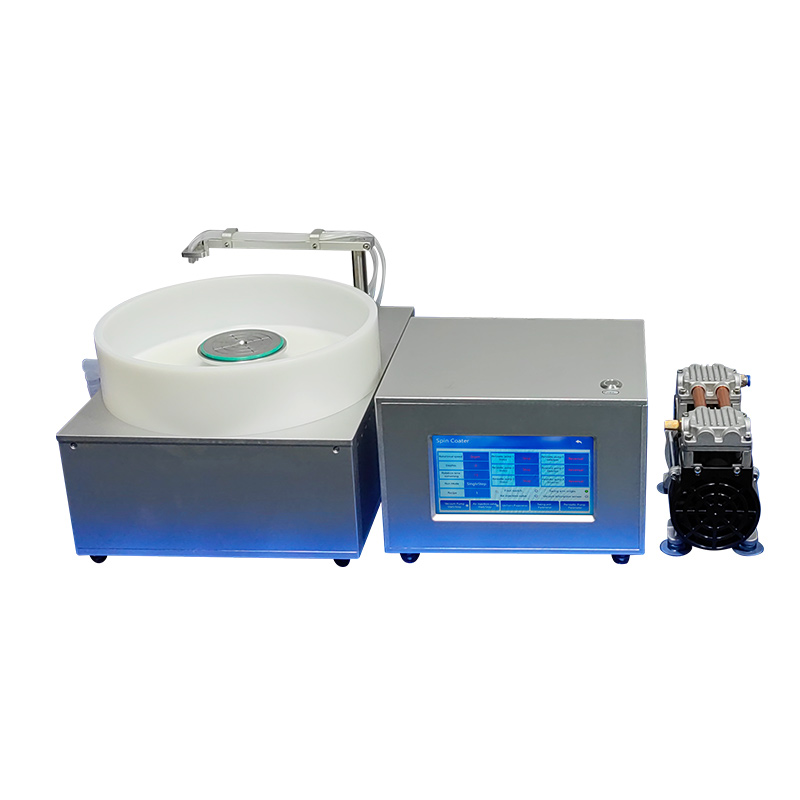

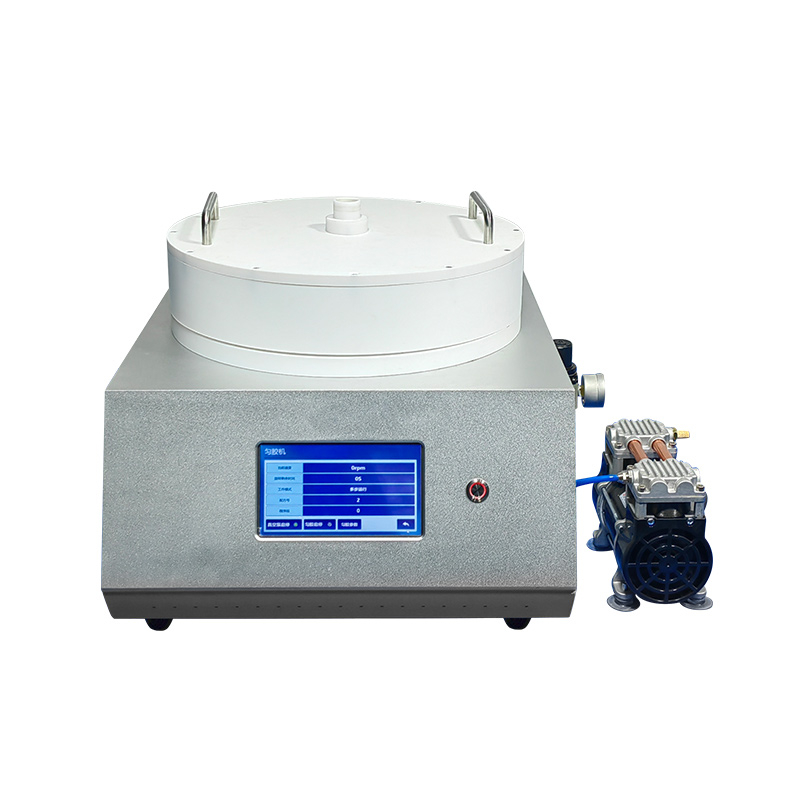

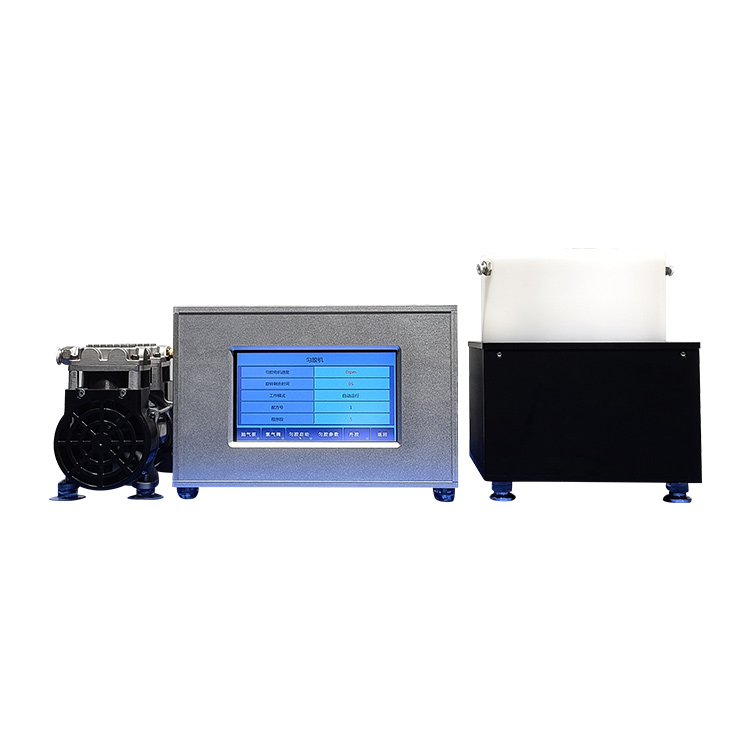

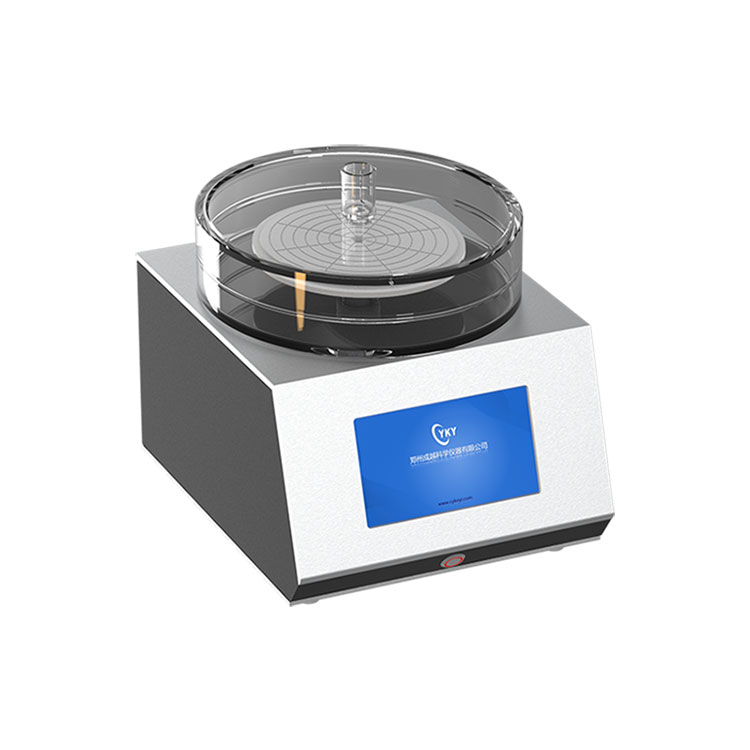

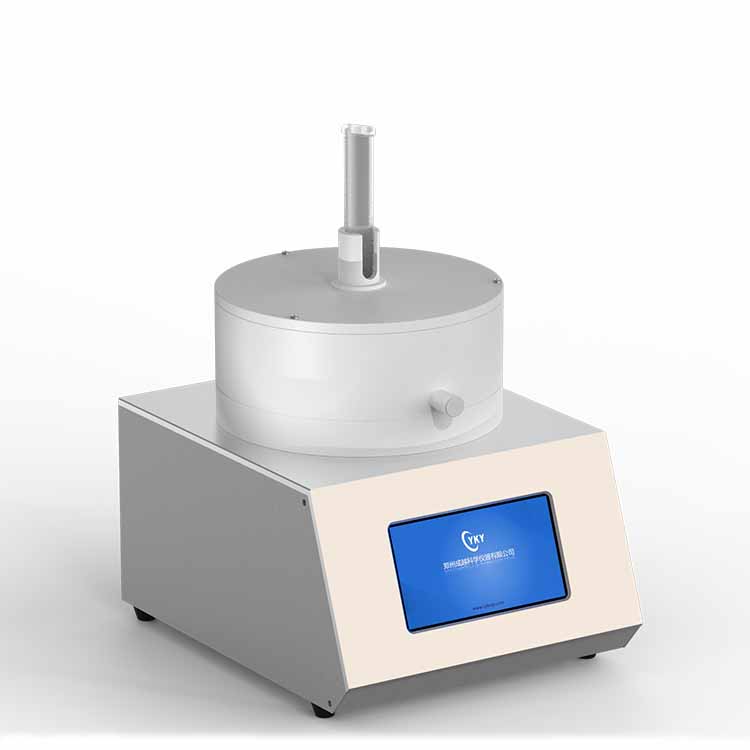

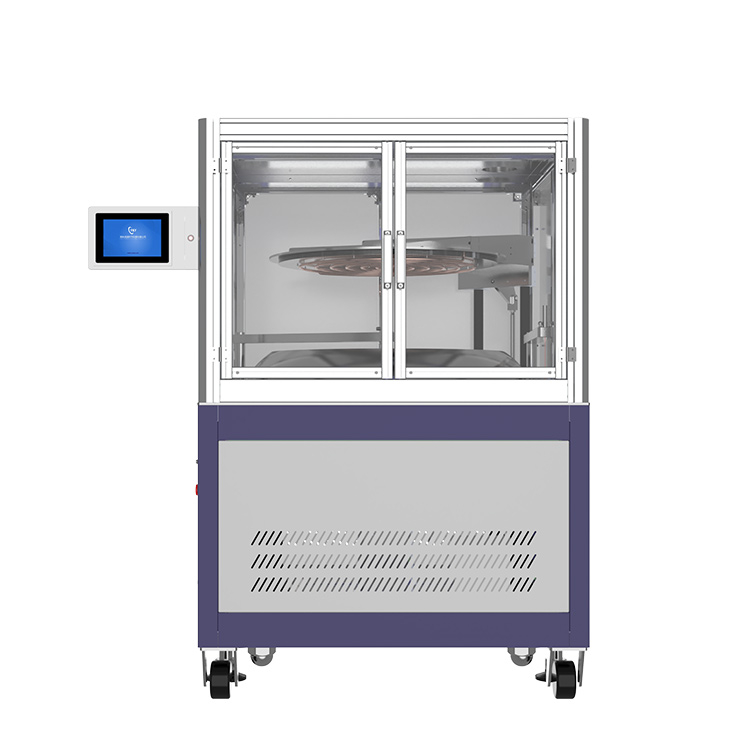

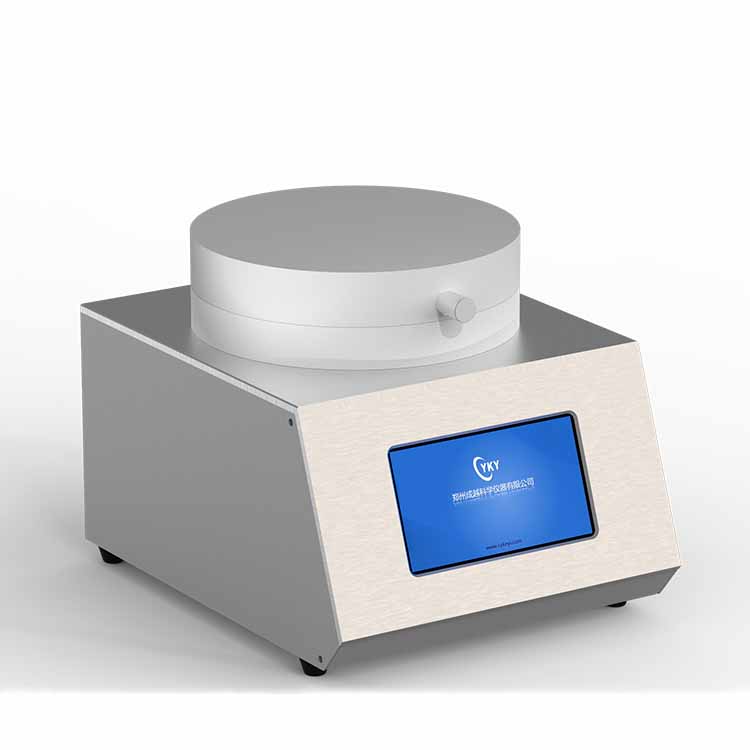

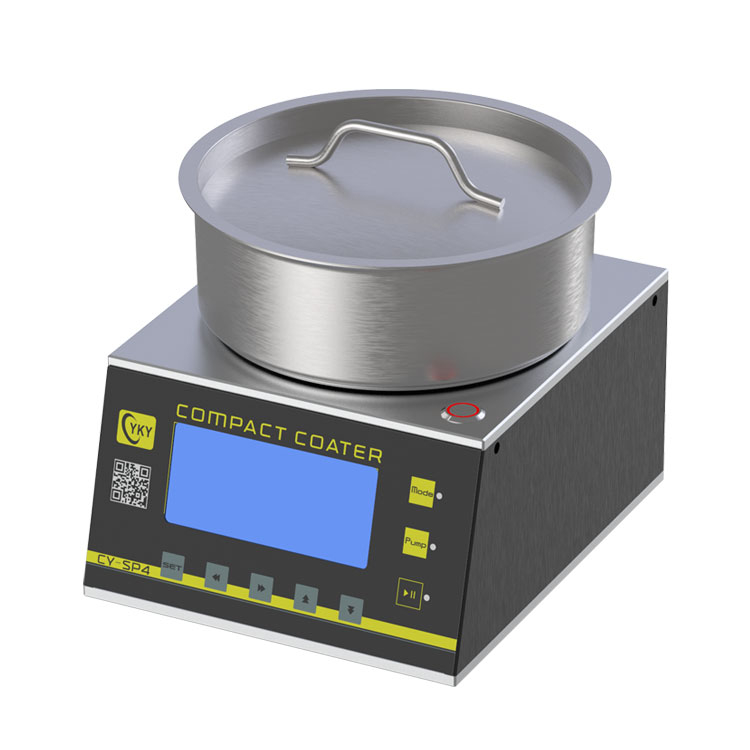

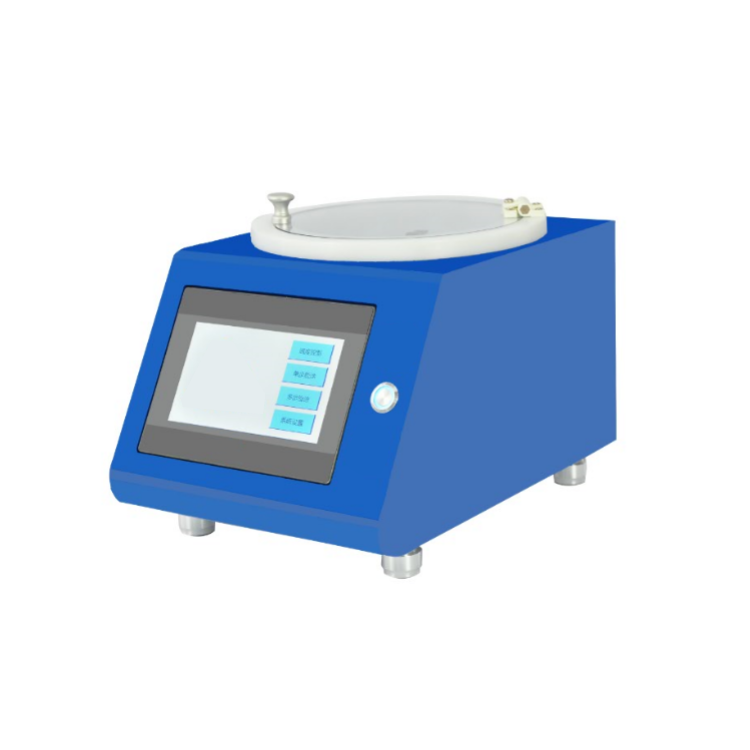

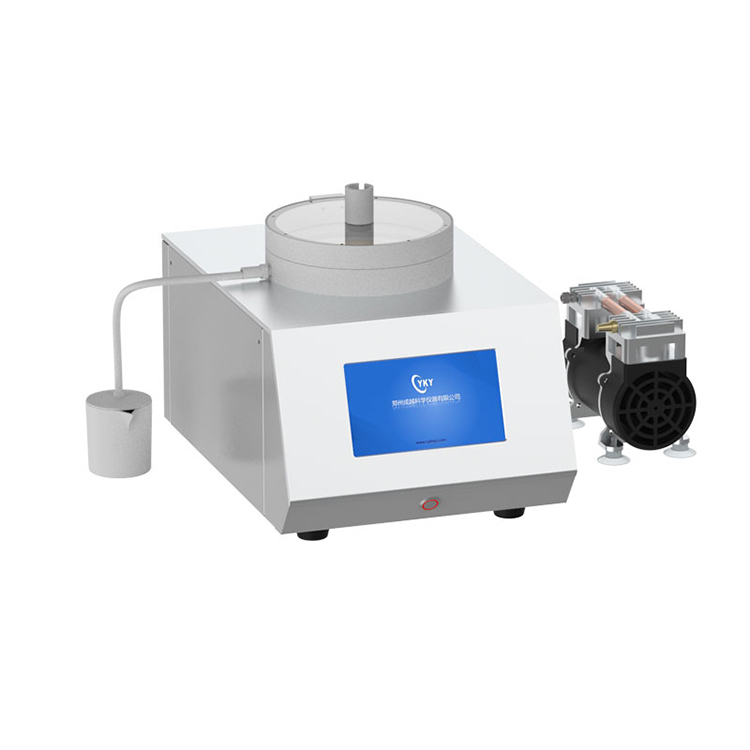

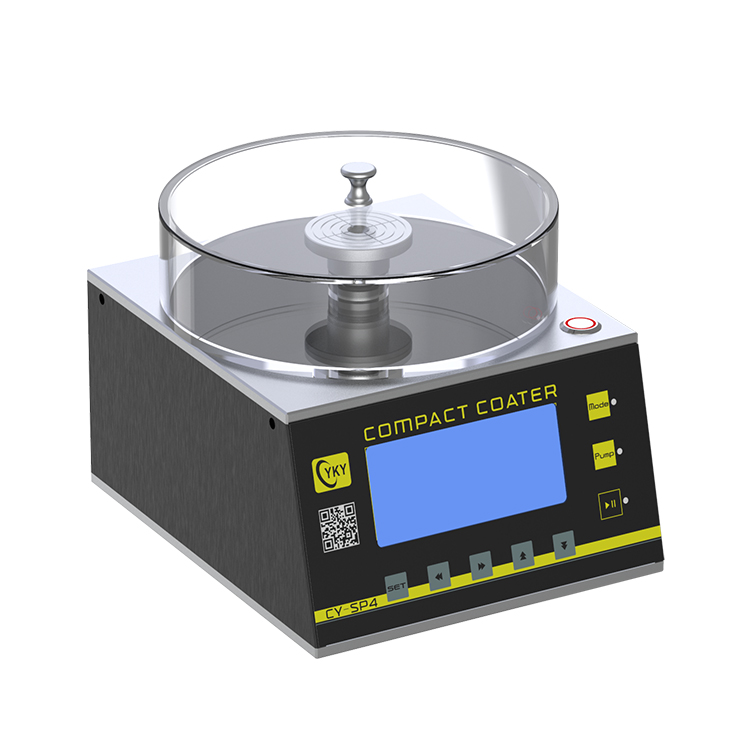

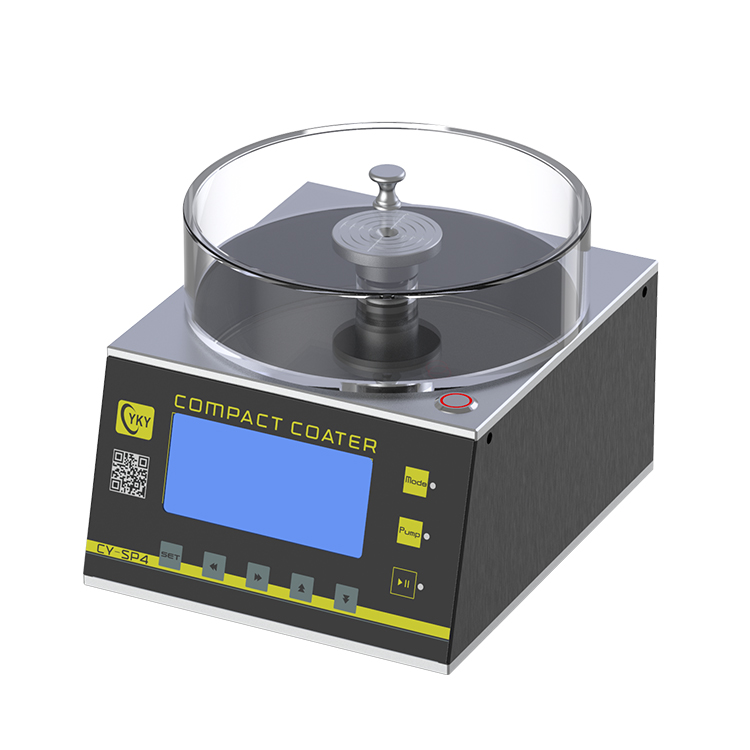

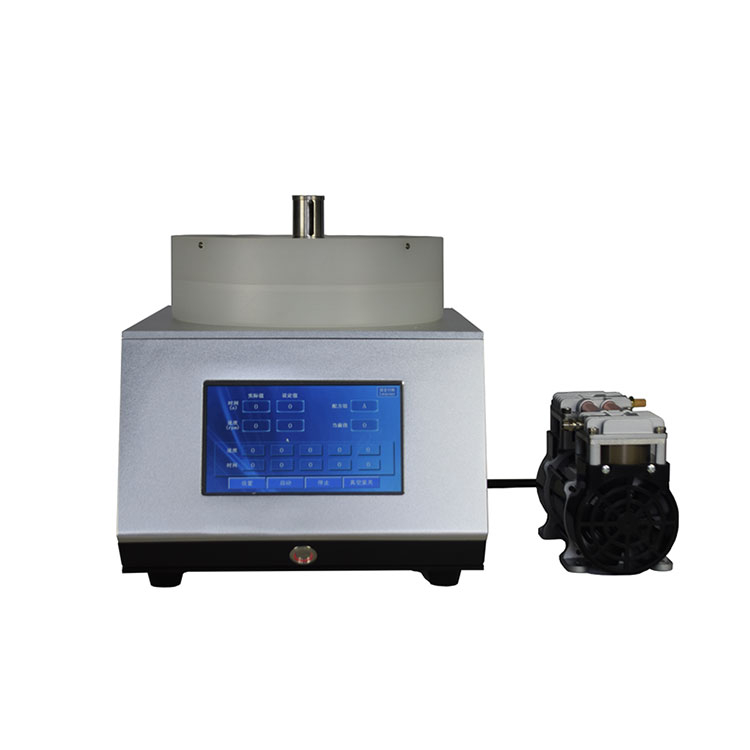

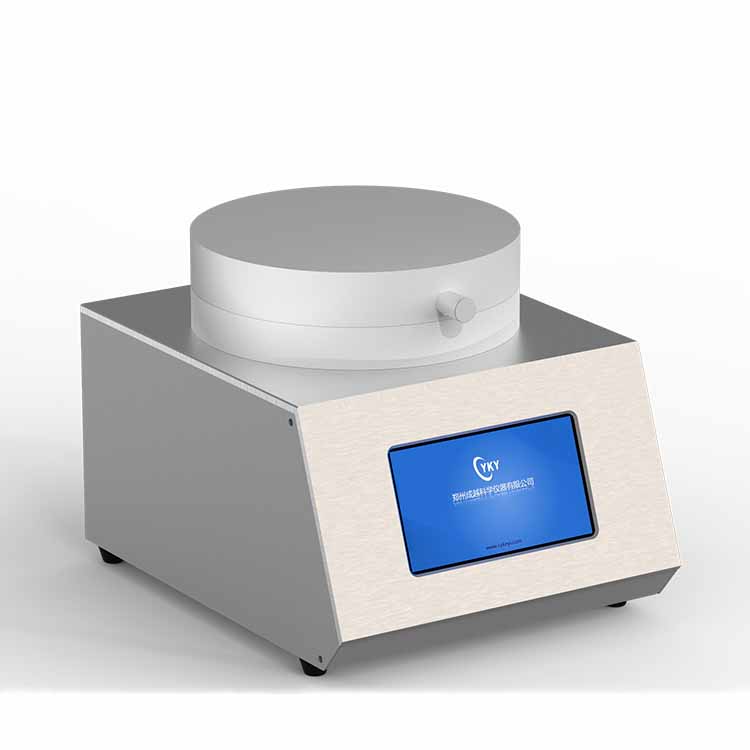

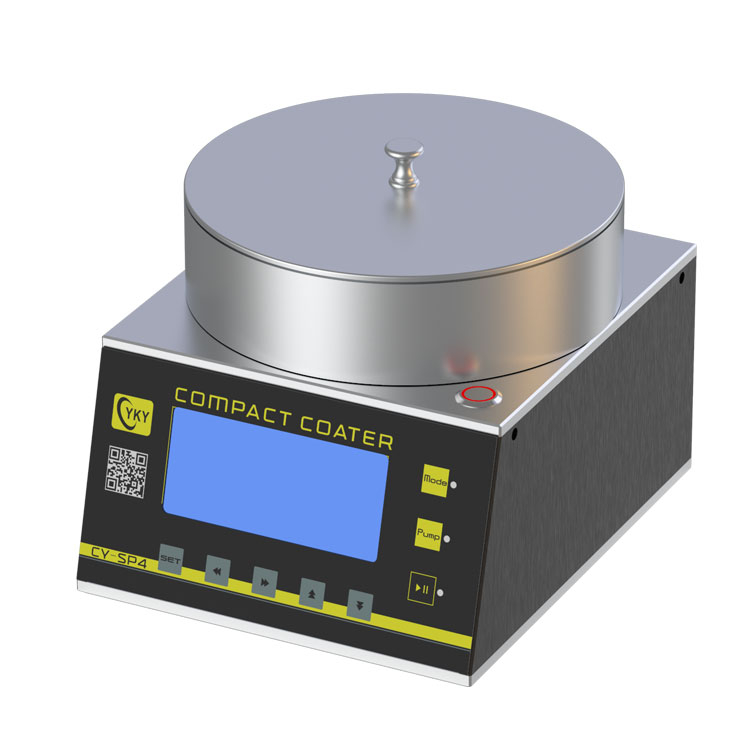

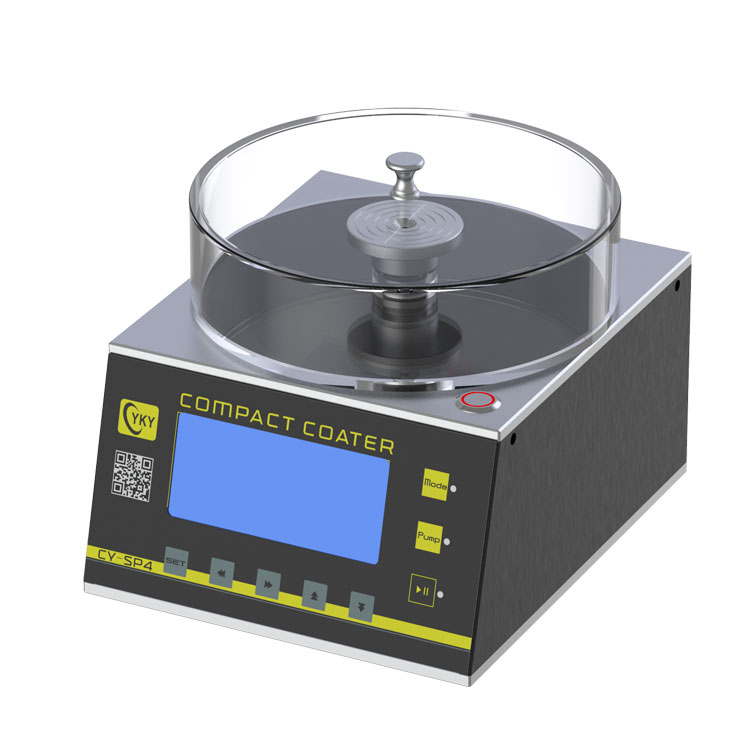

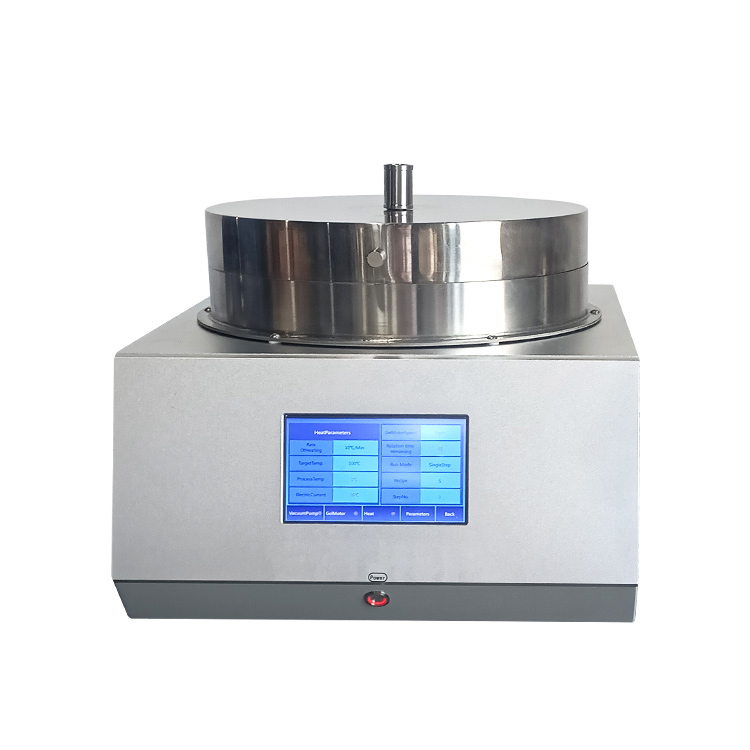

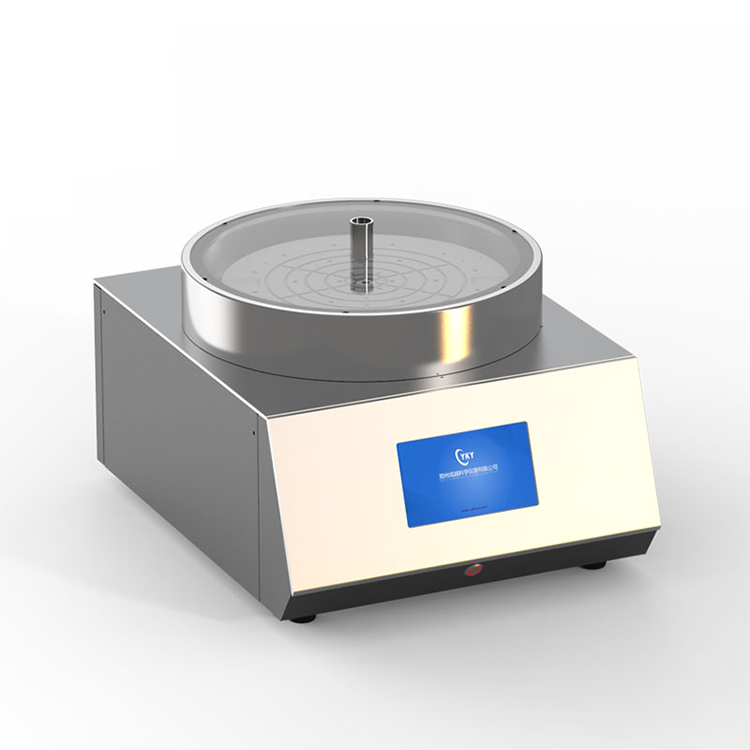

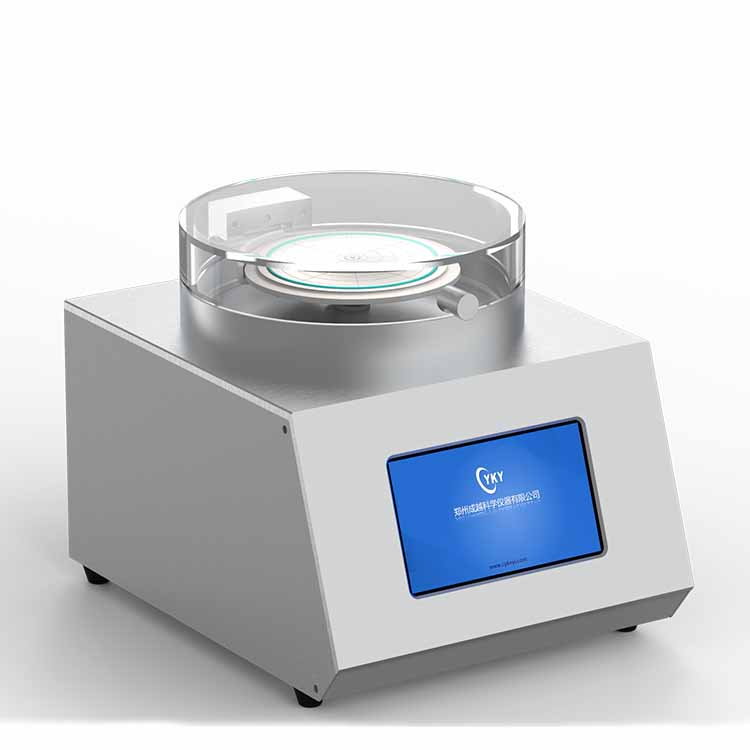

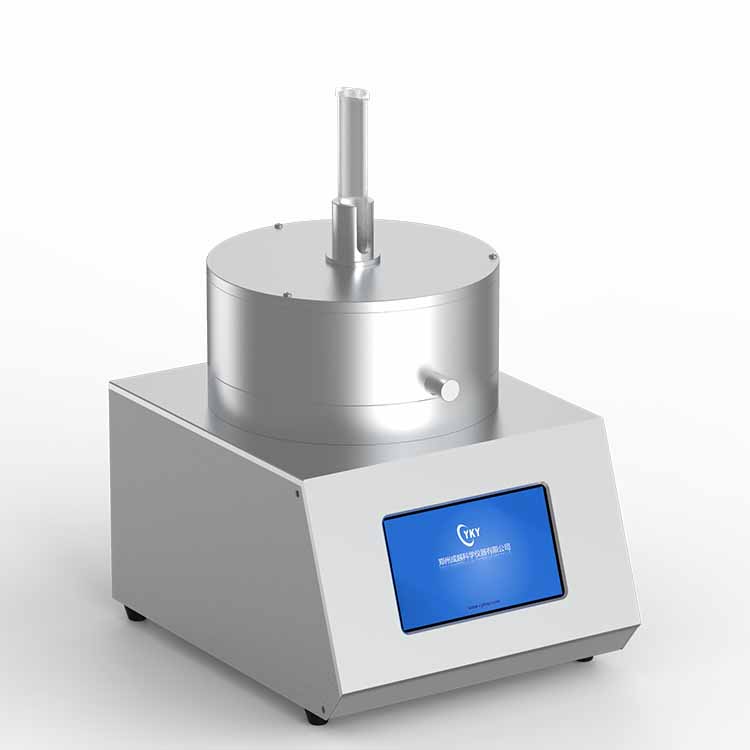

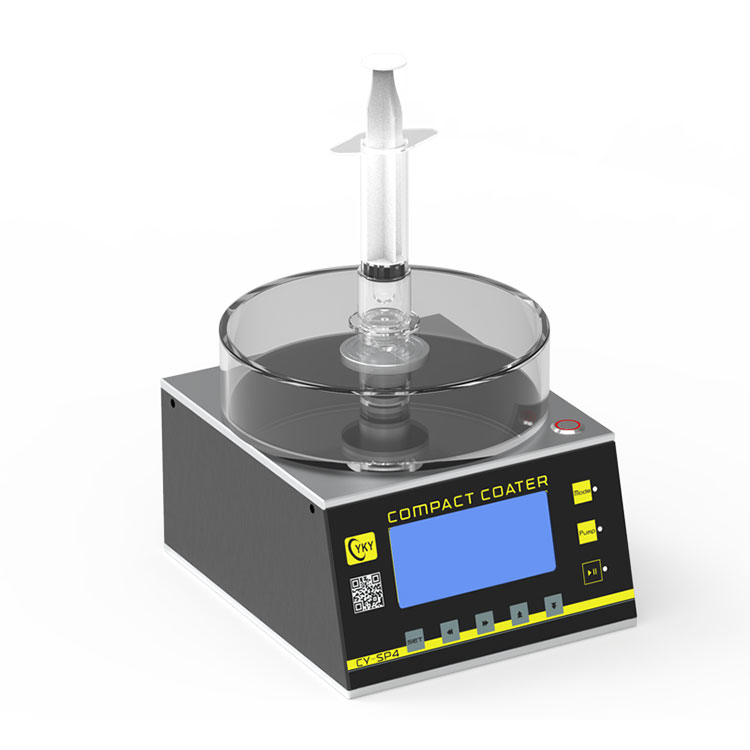

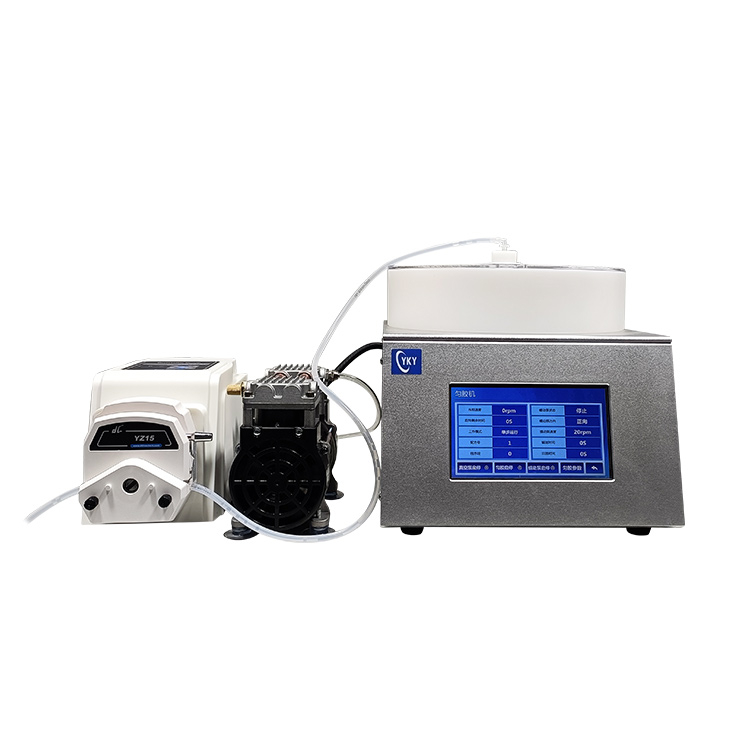

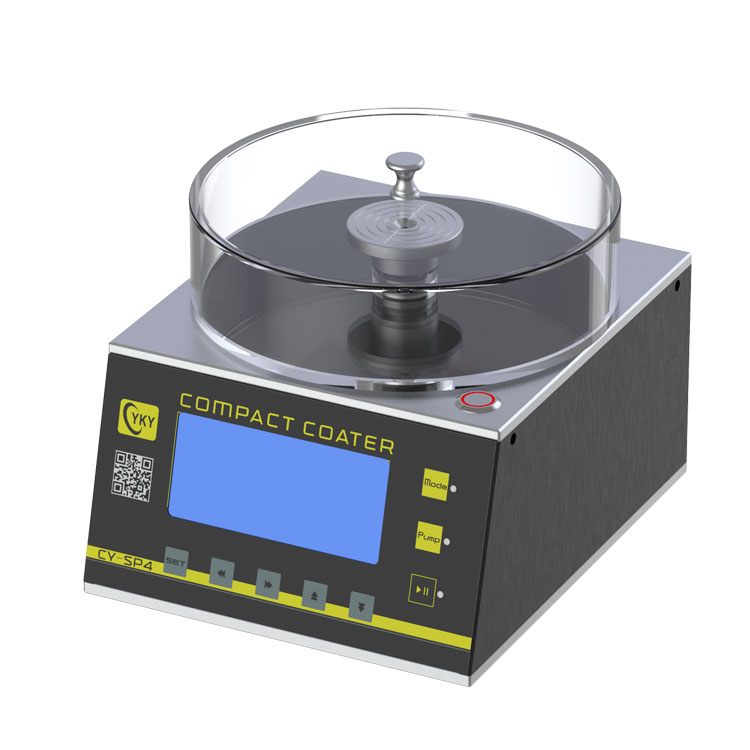

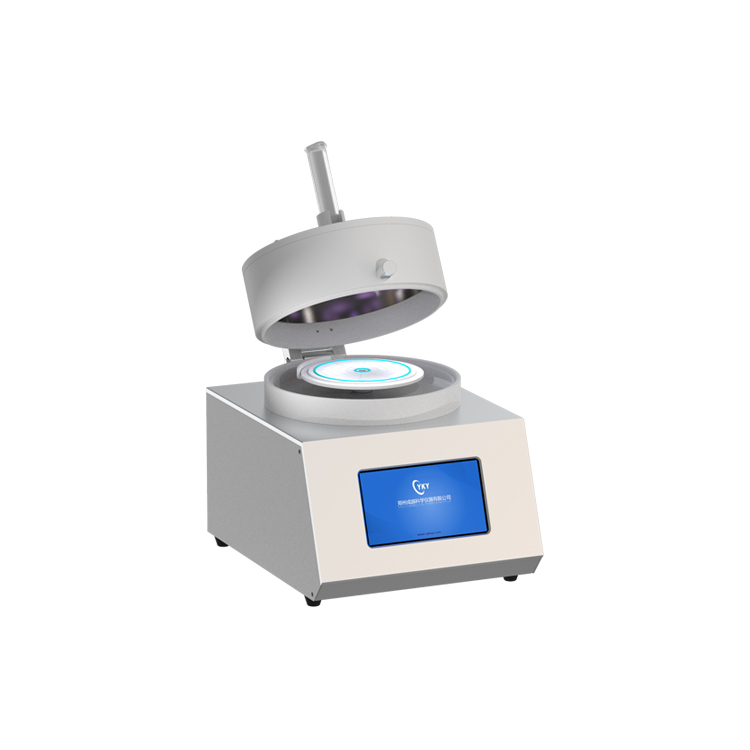

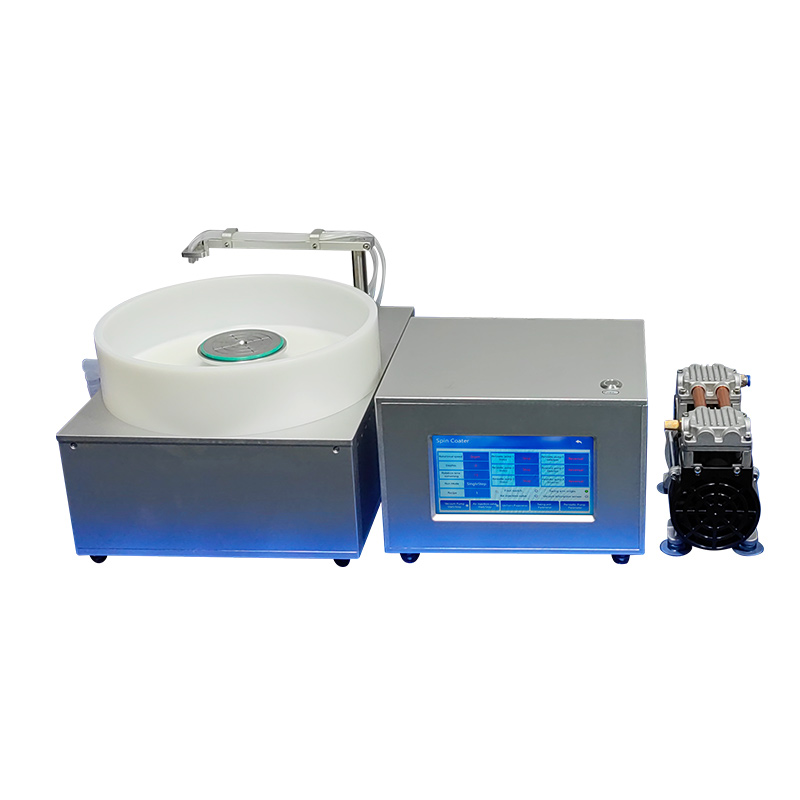

The swing arm spin coater mainly uses the centrifugal coating principle to coat liquid or colloidal materials on silicon wafers, crystals, quartz, ceramics and other substrates to form a thin film. This process is widely used in the field of materials research. The instrument uses an advanced precision motor, and the speed can reach 10,000 rpm, which effectively ensures the uniformity of film formation. In addition to the basic spin coating function, this product is equipped with a swing arm, which can achieve semi-automatic or fully automatic glue coating through the combination of the swing arm and the peristaltic pump. In addition, this instrument uses a touch screen control, and the glue coating curve can be preset, which greatly simplifies the use process and reduces the learning cost. It is very suitable for laboratory purchase. This instrument uses a split controller and host. The host is in the glove box, and the controller is outside the glove box, which can prevent chemicals from corroding the screen.

Technical Parameters:

Product name | swing arm spin coater |

Product model | CY-SPC8-BB-PP |

Maximum speed | 10000 RPM |

Speed resolution | 1 RPM |

Maximum rotation time | 3000 S |

Spin time resolution | 1 S |

Maximum acceleration | 5000RPM/S |

Liquid distribution | 3 peristaltic pumps, flow range 0.008ml/min-83.5ml/min |

Swing arm speed | 0-30°/S |

Cavity size | Inner diameter 260mm |

Dimensions | 310mm(W)x400mm(D)x250mm(H) |

Weight | 20kg |

Power input | AC220V 50/60Hz |

Evacuation rate | 50L/min |

Vacuum interface | Φ6mm Quick-twist connector |