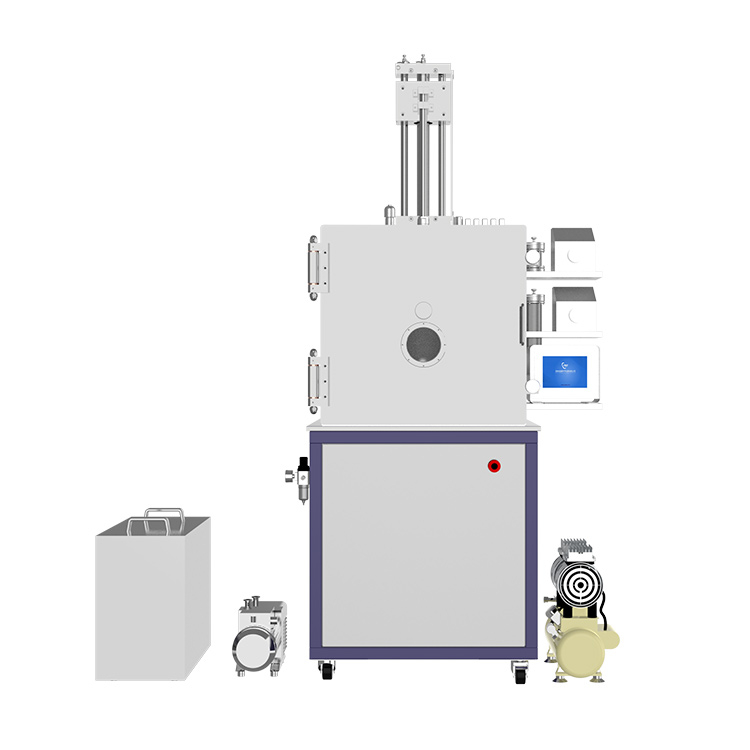

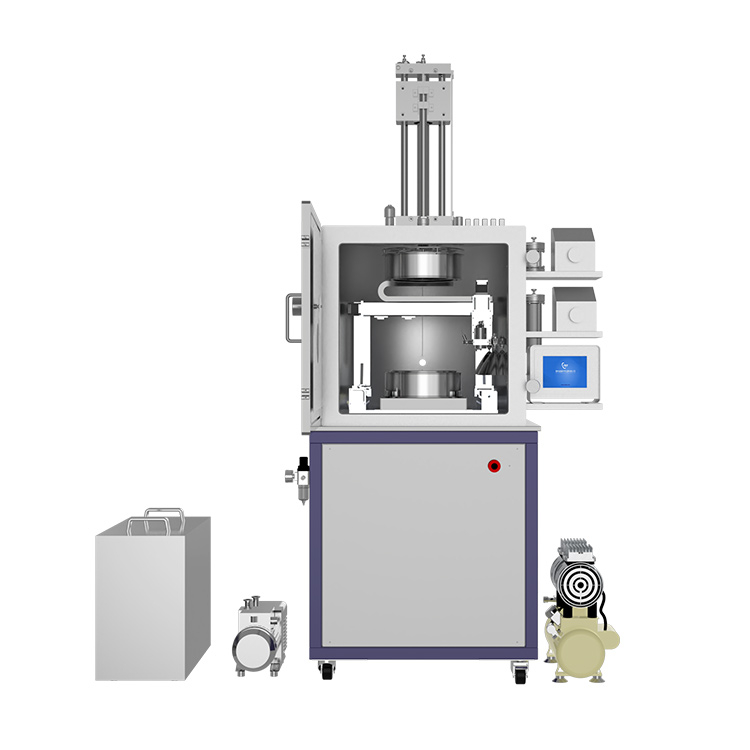

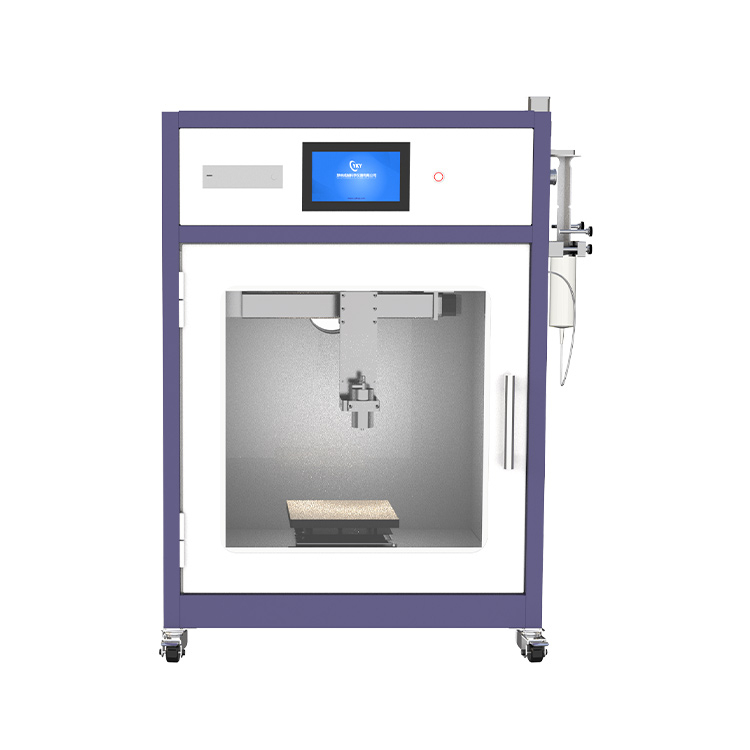

The high vacuum spray pyrolysis coater is an automatic spray pyrolysis equipment with a stainless steel chamber and a molten tin bath heater. The vacuum spray pyrolysis coater includes three compressed gas spray heads to achieve multi-layer thin film coating. Compared with conventional SS hot plates, the tin bath heater provides uniform and stable heating to the substrate during the coating process. The SS304 chamber ensures a clean and healthy atmosphere suitable for the most demanding experimental requirements.

Details:

The vacuum spray pyrolysis coater contains a software for the automation of the spray head movement and the dispensing rate. A positive displacement pump controlled by a stepper motor is used to dispense the solution as needed. The spray head sprays a fine atomized solution on the substrate, and its movement is controlled in the X and Y directions by a linear stage driven by a stepper motor to ensure uniform coating. The spray pattern and speed can be adjusted by changing the compressed gas pressure at the nozzle.

Spray pyrolysis is a process of depositing thin films by spraying a solution on a heated surface, where the components react to form compounds. The method is particularly useful for the deposition of oxides and has long been a manufacturing method for applying transparent conductors of tin oxide (SnO2) or tin oxide to glass substrates. Now, this technology is increasingly used to prepare perovskite films, such as perovskite solar cells.

Ultrasonic pyrolysis spray machine technical parameters:

Product name | High vacuum high temperature ultrasonic pyrolysis spraying |

Product model | CY-TSC-200*200-T |

Control method | Automatic touch screen control |

Sample size | Φ200mm |

Low vacuum | 5.0x10-4pa (molecular pump) |

Power supply voltage | AC220V, 50/60Hz |

Maximum power | 3.5KW |

Ultrasonic atomizer | 50KHz 30W |

Liquid viscosity | 1-50mPa·s (cP) |

Nozzle stroke | X-Y axis maximum 260mm |

Moving speed | 0-80mm/s (x-axis direction) 0-80mm/s (Y-axis direction) |

Heating substrate | Φ200mm |

Maximum temperature | 1000℃ |

Temperature control method | AI-PID temperature control |

Exhaust device | The equipment is equipped with an exhaust device so that the decomposed gas can be discharged from the exhaust port device |

Injection method | Large flow injection pump |

Communication protocol | Windows system, the default communication port is RS485 or RS232 |

Dimensions | 780x780x1500 |

Weight | 300KG |