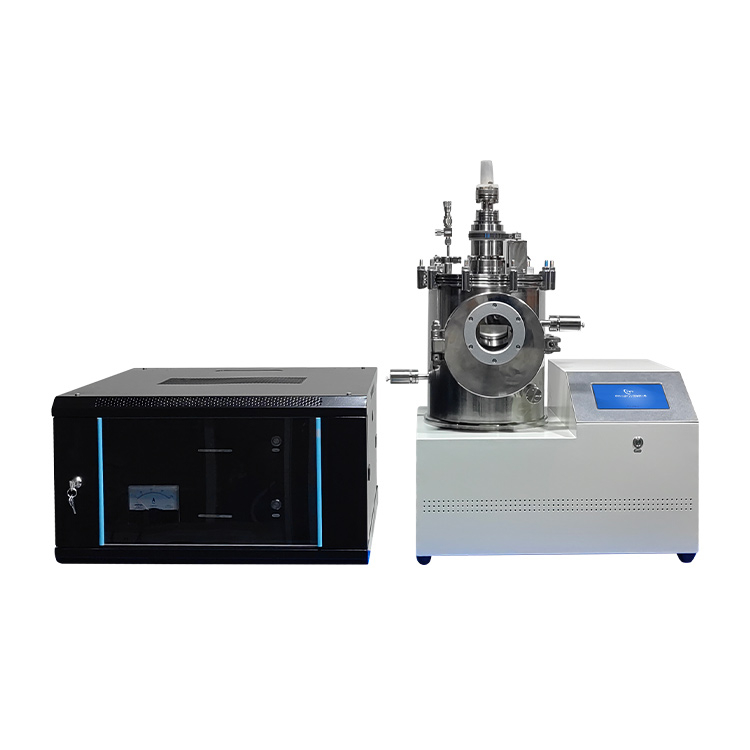

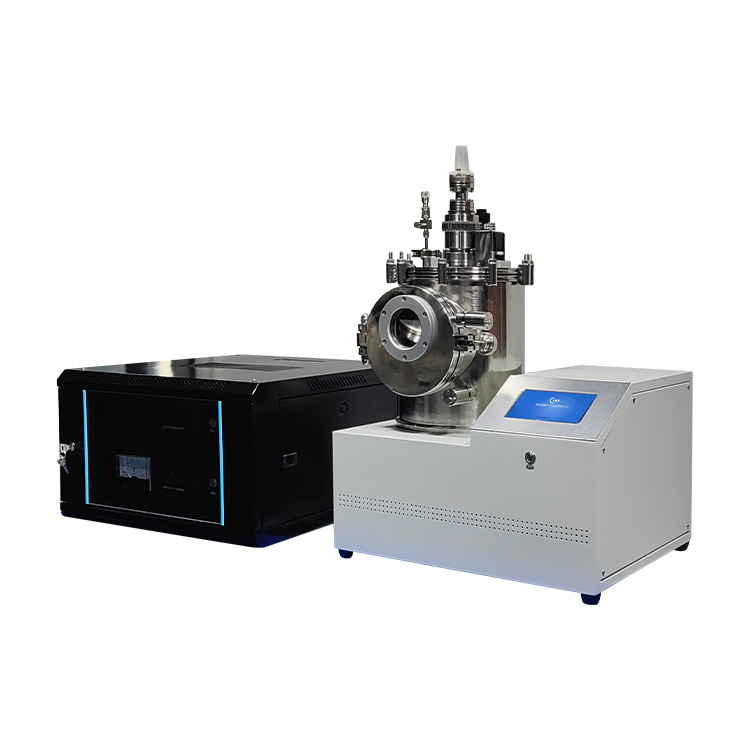

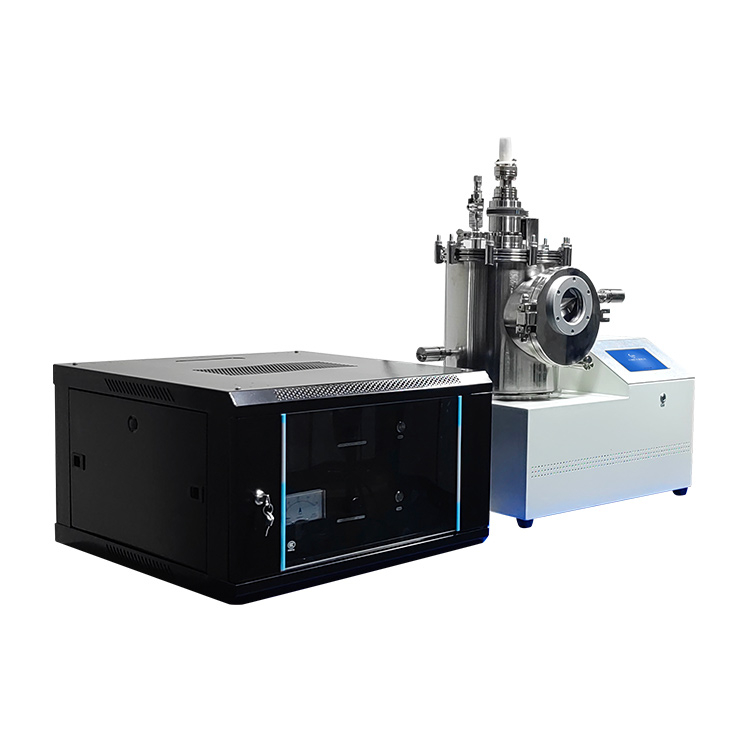

This dual-function coating instrument combines plasma sputtering and thermal evaporation, equipped with a DC sputtering target and thermal evaporation components. It is capable of both metal film coating through plasma sputtering and elemental thin film deposition through evaporation, such as carbon or other metals. The instrument features highly integrated components, enabling both coating functions within a single chamber. The coating instrument uses a 304 stainless steel chamber as the vacuum chamber, making the coating process fully visible. It comes standard with a dual-stage rotary vane vacuum pump, which can quickly achieve a vacuum level of 1.0E-4Pa, with an ultimate vacuum of 1.0E-5Pa, suitable for most evaporation coating experiments and DC sputtering experiments. The instrument is compact, space-saving, can be placed on a laboratory bench, and offers multiple functions in one machine, making it highly cost-effective and ideal for universities and research institutions.

Application Range of the Dual-Function Coating Instrument: The composite coating instrument with thermal evaporation and plasma coating is suitable for operations such as gold sputtering and carbon evaporation for scanning electron microscope (SEM) sample preparation, as well as for the preparation of electrodes for non-conductive material testing.

This instrument is highly recommended for use in various universities and research institutions.

Technical Parameters:

Product name | Thermal Evaporation coater and Plasma Coater |

Product model | CY-EVZ270-I-HP-SS |

Sample stage | Position | Top settings |

Dimensions | diameterφ150mm |

Speed | 0-20 rpm Adjustable |

Adjustable temperature | ≦500℃ |

Thermal evaporation source | Tungsten Boat |

Evaporation power supply | Evaporation source with an independent power supply |

Sputtering power supply | DC power supply |

Sputtering target | Quantity 2”×1 |

Vacuum chamber | Cavity size | Diameter φ273mm×H300mm |

Observation window | Diameter φ80mm |

Cavity material | 304 stainless steel |

Opening method | Front door |

Film thickness measurement | Crystal film thickness measuring instrument (film thickness controller is also optional) |

Vacuum system | Foreline pump | Bipolar rotary vane pump, gas pumping speed 1.1L/S |

Secondary pump | Turbomolecular pump, gas pumping speed 60L/S |

Vacuum measurement | Compound vacuum gauge (ionization gauge + resistance gauge) |

System vacuum | 5×10-4Pa |

Control System | CYKYSelf-developed professional-grade controller |

Other parameters | Power supply | AC220V,50Hz |

Complete size | 600mm×500mm×850mm |

Complete power | 7KW |

Complete weight | 120kg |