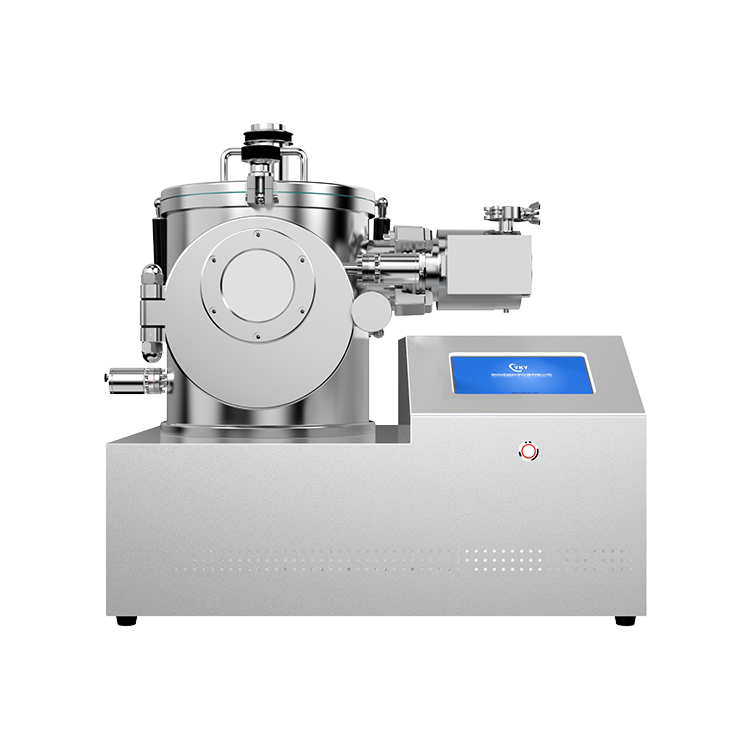

The high-vacuum dual-source thermal evaporation coating machine is an advanced evaporation coating instrument equipped with two evaporation sources. It utilizes tungsten filament baskets (or tungsten boats) as the evaporation sources, and the distance between the sample stage and the evaporation sources is adjustable. This instrument can stably evaporate metals and certain organic materials. Featuring a high-vacuum stainless steel chamber with excellent sealing performance and vacuum properties, it ensures a reliable vacuum environment. The chamber is equipped with an observation window, allowing for visual monitoring of the coating process. Equipped with a molecular pump system, it can achieve an ultimate vacuum of 10E-5Pa, which significantly enhances coating quality and meets the vacuum requirements of most evaporation coating experiments.

The high-vacuum thermal evaporation coating machine is a widely used experimental equipment in chemistry, materials science, physics, and other fields. Its primary applications encompass the following aspects:

I. Film Preparation

Metal Film Evaporation: The high-vacuum thermal evaporation coating machine is particularly suited for evaporating oxygen-sensitive metal films (such as Ti, Al, Au, etc.). These metal films have extensive applications in electronic devices, optical devices, sensors, and other fields.

Oxide Material Evaporation: This instrument is also suitable for evaporating various oxide materials, which are of significant value in functional films, ceramic coatings, photoelectric materials, and other aspects.

Organic Material Evaporation: By modifying certain configurations, the high-vacuum thermal evaporation coating machine can also evaporate organic materials, fulfilling research demands in light-emitting devices, organic solar cells, and more.

II. Sample Preparation and Modification

Electron Microscope Sample Preparation: During the preparation of samples for electron microscopes (e.g., scanning electron microscopes, transmission electron microscopes), the high-vacuum thermal evaporation coating machine can deposit a thin film on the sample surface to improve its conductivity, protect the sample surface, or enhance imaging quality.

Surface Modification: Through evaporation coating technology, a thin film can be formed on the surface of the substrate material, thereby altering its surface properties, such as improving wear resistance, corrosion resistance, optical performance, etc.

III. Scientific Research and Education

Scientific Research Experiments: The high-vacuum thermal evaporation coating machine is an indispensable experimental equipment in scientific research activities, used for the research and development of various new materials and processes.

Educational Experiments: In the teaching of material science, physics, and related disciplines, this instrument can also be used to demonstrate the principles and operation processes of evaporation coating technology, helping students better understand and grasp relevant knowledge.

IV. Process Testing

Process Optimization: By conducting process tests with the high-vacuum thermal evaporation coating machine, the impact of different evaporation conditions (e.g., temperature, vacuum level, evaporation rate) on coating quality can be evaluated, thereby optimizing evaporation coating process parameters.

Quality Control: In industrial production, this instrument can also be used for quality control and inspection of coated products, ensuring that product performance meets relevant standards and requirements.

In summary, the high-vacuum thermal evaporation coating machine boasts extensive application value in film preparation, sample preparation and modification, scientific research and education, as well as process testing. With the continuous development of science and technology, the application of this instrument in more fields will continue to expand and deepen.

High vacuum thermal evaporation coating instrument technical parameters:

Product name | High vacuum dual source thermal evaporation coating |

Product model | CY-EVV195-II-HH-SS |

Sample stage | Position | Top setting |

Dimensions | Diameter φ65mm |

Speed | 0-20 rpm |

Pitch | Adjustable distance between sample holder and evaporation source |

Adjustable temperature | ≦500℃ |

Thermal evaporation source | Tungsten wire basket × 2, tungsten boat × 2 |

Evaporation power supply | Each evaporation source is equipped with an independent power supply; two evaporation sources can be evaporated at the same time |

Vacuum chamber | Cavity size | diameterφ195mm×H210mm |

Observation window | diameterφ100mm |

Cavity material | 304 Stainless steel |

Opening method | Open cover |

Film thickness measurement | Crystal film thickness measuring instrument (film thickness controller is also optional) |

Vacuum system | Foreline pump | Bipolar rotary vane pump, gas pumping speed 1.1L/S |

Secondary pump | Turbomolecular pump, gas pumping speed 600L/S |

Vacuum measurement | Compound vacuum gauge (ionization gauge + resistance gauge) |

System vacuum | 5×10-4Pa |

Control System | CYKYSelf-developed professional-grade controller |

Other parameters | Power supply | AC380V,50Hz |

Complete size | 600mm×650mm×1500mm |

Complete power | 7KW |

Complete weight | 260kg |