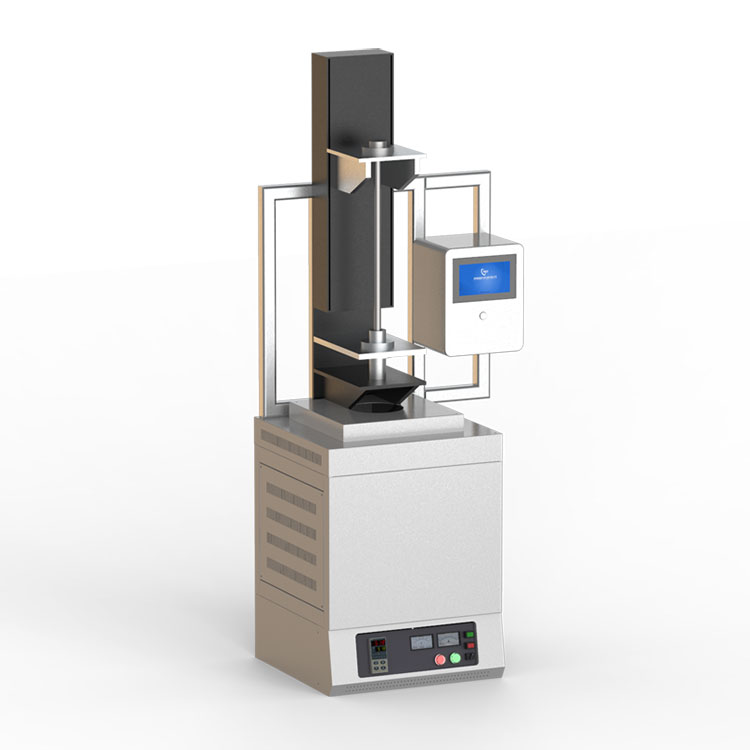

CY-BG-1200 is a small 1200℃ Bridgman single crystal growth furnace, equipped with an inner diameter of Φ72mm quartz tube and a precise furnace body moving mechanism (maximum stroke 200mm), This equipment is designed to grow small size single crystals or directional solidification of materials in a controlled atmosphere

Technical parameters of Bridgman crystal growth furnace:

Working voltage | 208~240VAC |

Maximum power | 4KW |

Heating temperature zone | 2 heating temperature zones: each temperature zone is 100mm, the total temperature zone length is 200mm |

Maximum heating temperature | 1200℃ |

Continuous working temperature | 1100℃ |

Thermostat | 2 program temperature controllers, independently control 2 temperature zones, the temperature control accuracy can reach +/-0.1℃ |

Maximum temperature gradient | 1℃/cm |

• The user needs to find a suitable temperature gradient

•Can create different temperature gradients by adjusting the temperature of 2 temperature zones

• Adjusting the opening diameter of the furnace body can also change the temperature gradient

•The equipment contains quartz tube (outer diameter Φ80mm×inner diameter Φ72mm×length 800mm) and stainless steel sealing flange

Servo motor is used to drive the furnace body to move up and down

•The servo motor and high-precision linear module to ensure that the furnace body will not be stuck during the movement

•The furnace body has two modes of slow lifting and fast moving

•Maximum travel stroke: 200mm

•Movement speed range: 0.03mm/hr--30mm/hr (adjustable, accuracy +/-1um)

•The moving speed range of the furnace body can be customized according to customer requirements

Sealing flange

• A pair of stainless steel sealing flanges for sealing quartz tubes

• Pressure sensor and Φ6.35mm air outlet are installed on the top flange

• The bottom flange has KF25 vacuum interface and Φ6.35mm air inlet

•The bottom flange adopts stepping motor to drive up and down, which is used to load and take out the crucible

• The equipment is equipped with a graphite crucible with a diameter of Φ60mm×70mmH

•The crucible table is installed on the bottom flange

• Vacuum: 10-2torr (using mechanical pump), 10-5torr (using molecular pump system)

The touch screen control panel can control the moving speed of the furnace body, the moving stroke and the temperature of the furnace body and display the temperature of the crucible, and can also control the internal pressure of the furnace tube

• Set the pre-pull time in accordance with the heating furnace heating curve, for example, set it to start pulling after 5 hours

•Temperature curve function, always display two temperature control curves and the temperature curve at the bottom of the crucible, the temperature curve data can be saved, recorded and exported

• 2 Eurothermo instruments respectively control 2 temperature zones, with a temperature control accuracy of +/-0.1℃

• Contains 3 K-type thermocouples

2 thermocouples respectively control and detect the temperature of 2 temperature zones

1 thermocouple is used to detect the temperature at the bottom of the crucible

• Crucible platform and bottom flange are connected to each other

• A digital display pressure sensor and solenoid valve are installed on the sealing flange to control the constant air pressure in the furnace tube. The control range: 0.01MPa-0.02MPa