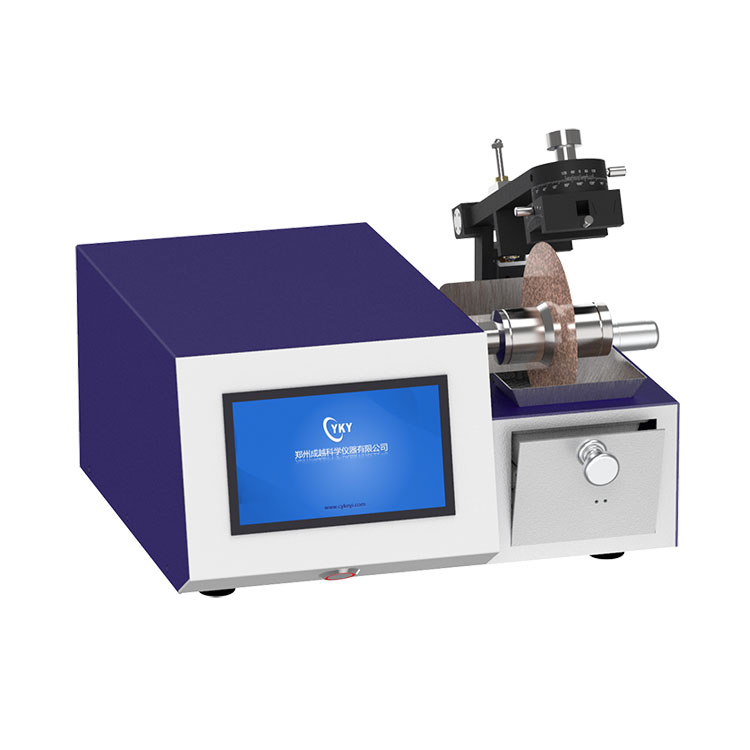

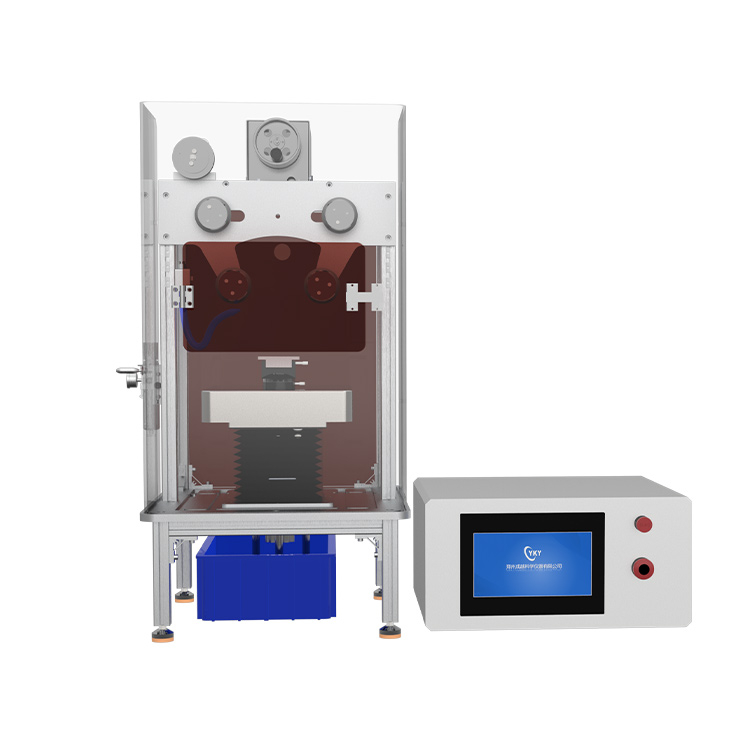

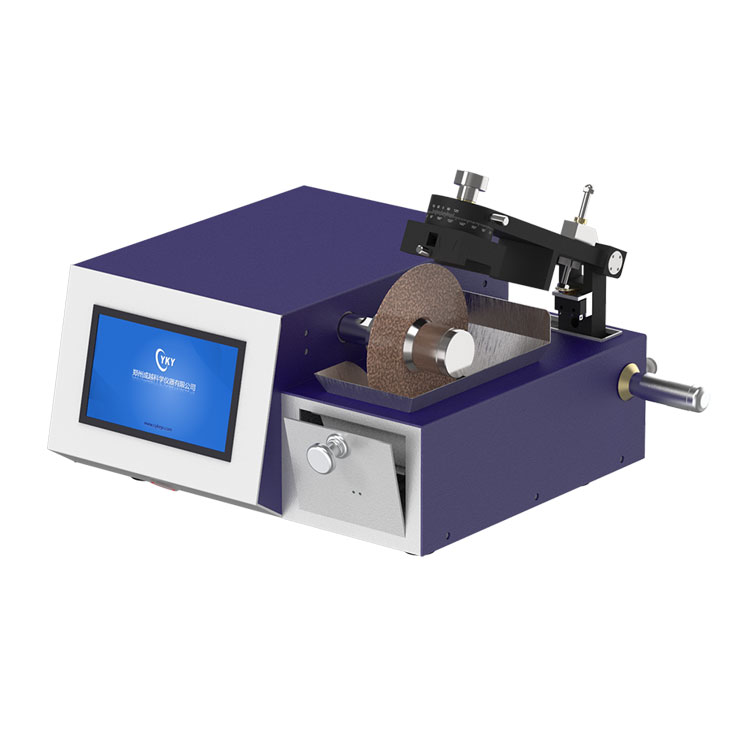

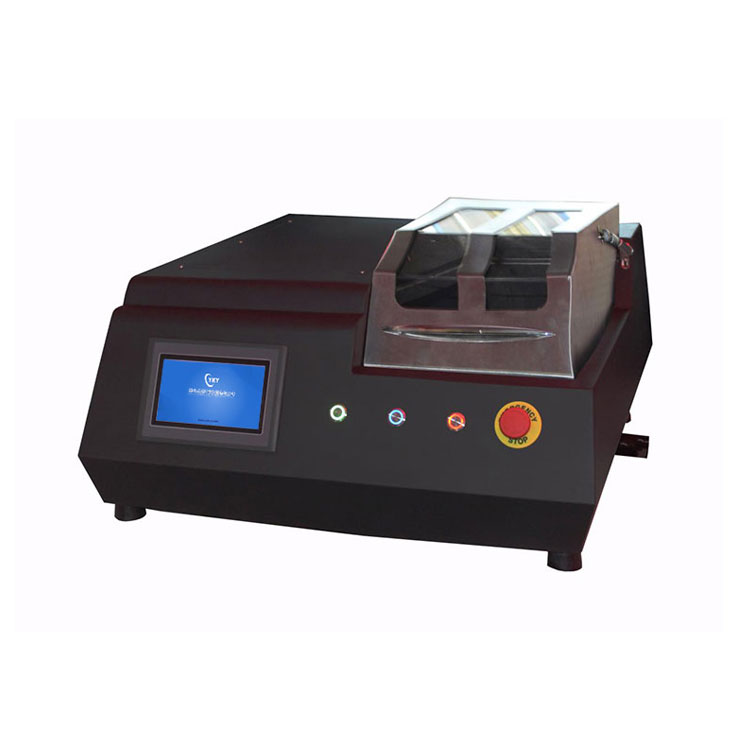

Functions | 1. Ceramic materials: alumina ceramics, zinc oxide ceramics, zirconia ceramics, target ceramics, honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc; 2. Crystal material: graphite, silicon crystal (solar polysilicon, monocrystalline silicon), sapphire, alumina crystal, infrared glass crystal, alumina crystal, silicon carbide crystal, cesium iodide crystal, etc.; 3. Glass materials: chalcogenide glass, optical glass, quartz glass, infrared glass, glass tube, etc.; 4. Metal materials: iron, aluminum, copper, titanium alloy, magnesium alloy and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc.; 5. Composite materials: PVC board, carbon fiber composite material, glass fiber composite material, etc. 6. Rock materials: precise sections of natural rocks, jade, meteorite, Peicui, agate and other high-value materials; geological optical slices, geological thin sections (sedimentary rocks, magmatic rocks, metamorphic rocks, ores), etc.. 7. Thermoelectric materials: bismuth telluride, lead telluride, silicon germanium alloy, etc. 8. Infrared optical materials: zinc selenide, zinc sulfide, silicon, germanium and other crystals 9. Biomedical materials:Bioplasticization specimen sections (human animal organs, jaw joint sections of soft and hard tissues, implant observation, tooth crown and bridge, teeth and other histological specimens); Combined sections of soft and hard tissues in orthopedics department (fresh tissues and hard tissues such as femur, hip joint and vertebral body, bone histological samples with implants, etc.); Cardiac and cerebrovascular stent section, stone section and other medical tissue sections; |

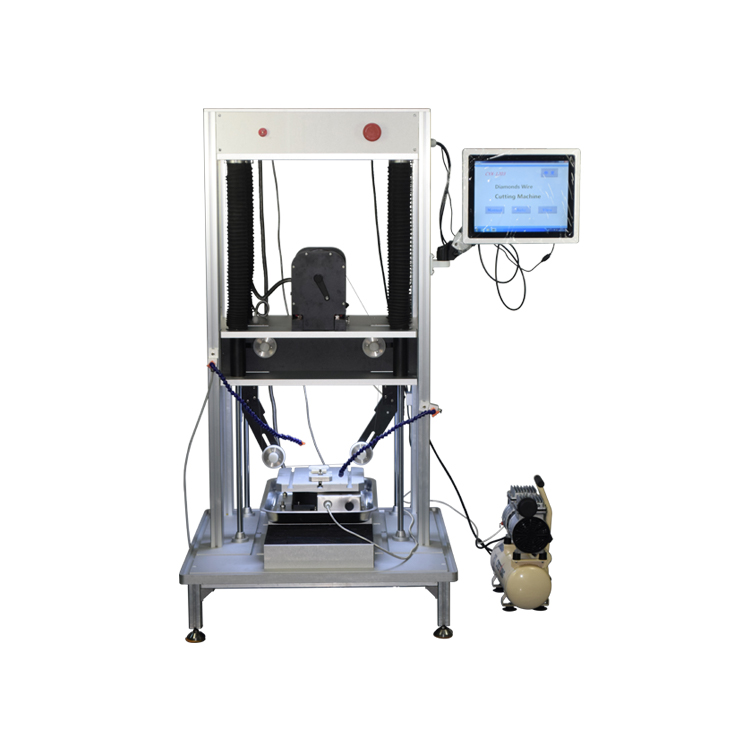

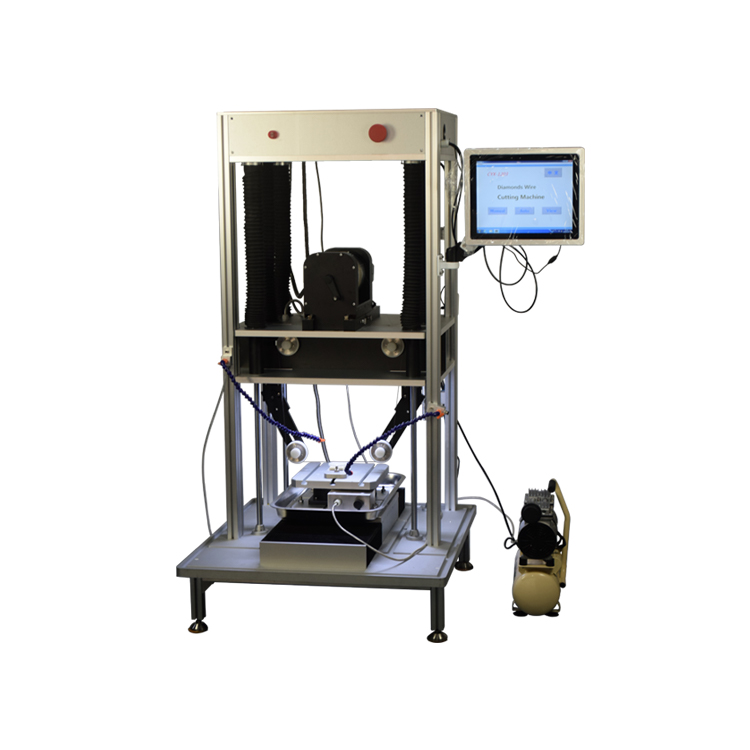

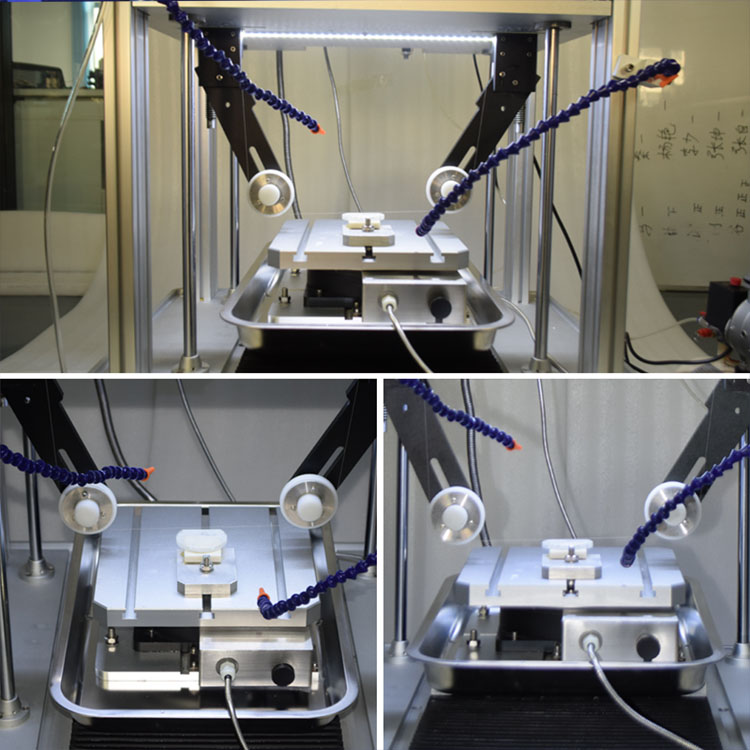

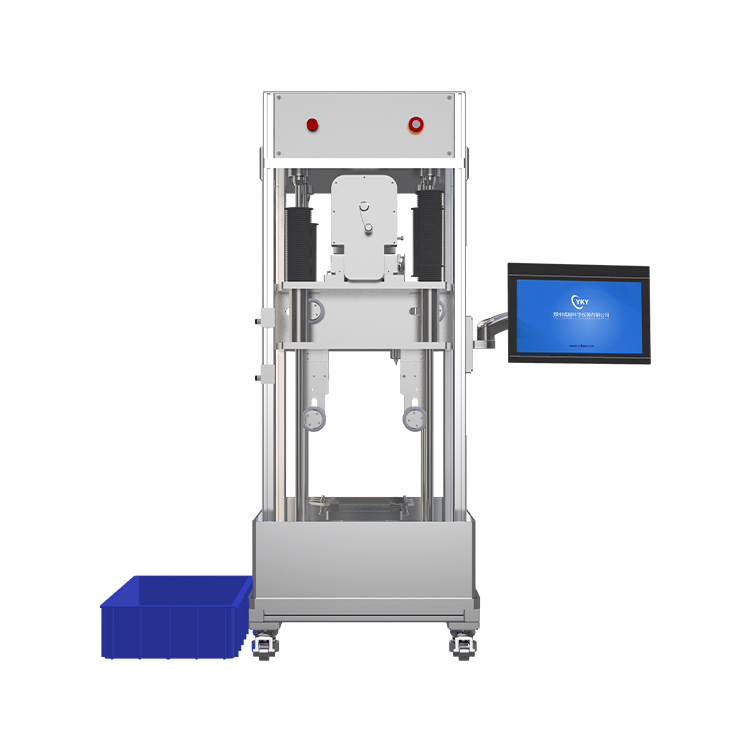

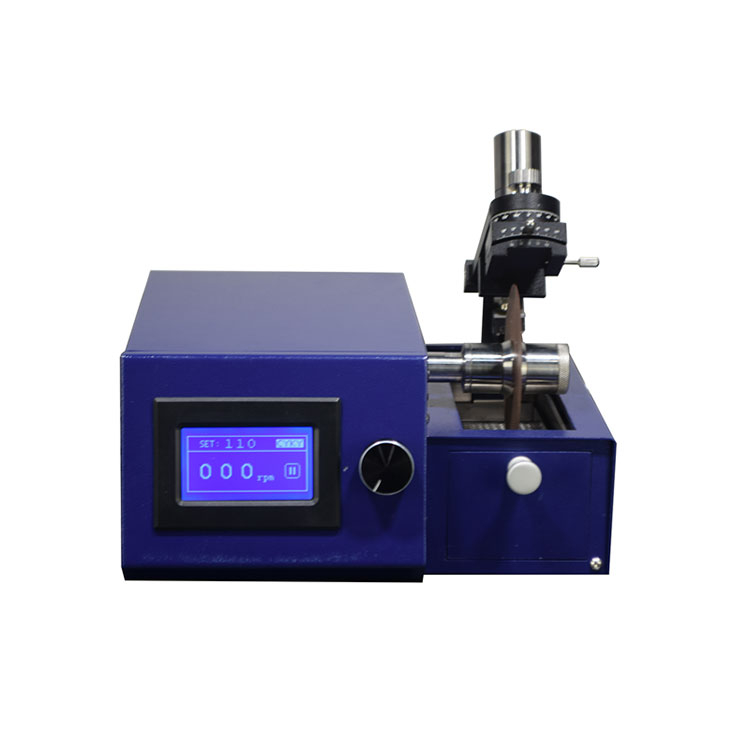

Parameters | 1. Power supply: 220 V 50 Hz; 2. Power: < 550W (max); 3. Spindle motor: AC frequency conversion motor, Power 400W; 4. Y, Z, R axis motor: precision stepping motor; 5. Cutting wire speed: 0-8m / s adjustable, digital display; 6. Total length of cutting line: ≤ 150m; 7. Cutting line diameter: ≤ 0.45mm; 8. Y axis travel: ≤ 300 mm, digital display; 9. Z axis travel: ≤ 300 mm, digital display; 10. Y, Z axis feed indication accuracy: 0.01mm; 11. Worktable angle: 0-360°, resolution 0.01°, digital display; 12. Repeated positioning accuracy of worktable: < 0.032° 13. Cutting sample size: Ø 300 mm × 300 mm (max); 14. Tension system: pneumatic tension, tension pressure adjustment range 0-1mpa; 15. Safety control device: self stop and emergency stop switch of line break |