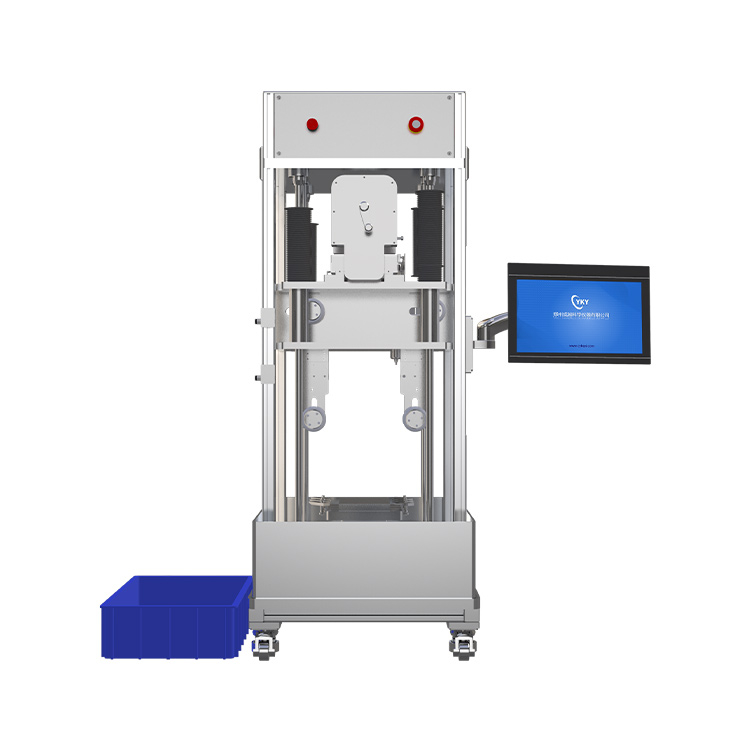

Product name | Fully automatic diamond wire cutting machine |

Product model | CY-DWC-M808 |

Technical parameters | Power supply | 220V 50Hz |

Power | <1.5KW(max) |

Spindle motor | Servo motor, power 750W |

Y, Z axis motor | Precision stepper motor |

Cutting wire feeding speed | 0-8m/s adjustable, digital display |

Cutting wire total length | ≤150m |

Cutting wire diameter | ≤0.35mm |

Y axis travel | ≤200mm,digital display |

Z axis travel | ≤200mm,digital display |

Y, Z axis feed indication accuracy | 0.01mm |

Workbench rotation angle | 0-360˚ |

Cutting sample size | Ø200mm×200mm(max) |

Tensioning system | Pneumatic tensioning, tensioning air pressure adjustment range 0-0.7Mpa |

Safety control device | Automatic stop when wire breaks, emergency stop switch |

Tensioning wheel | 2 piece |

Technical parameters | Guide wheel | 2 piece |

Diamond wire | 2 volume |

Water pump | 1 piece |

Resin ceramic block | 2 piece |

Paraffin rod | 4 piece |

Diamond wire | (Ø0.125mm、Ø0.25mm、Ø0.35mm、Ø0.42mm) |

Optional accessories | Special cutting oil |

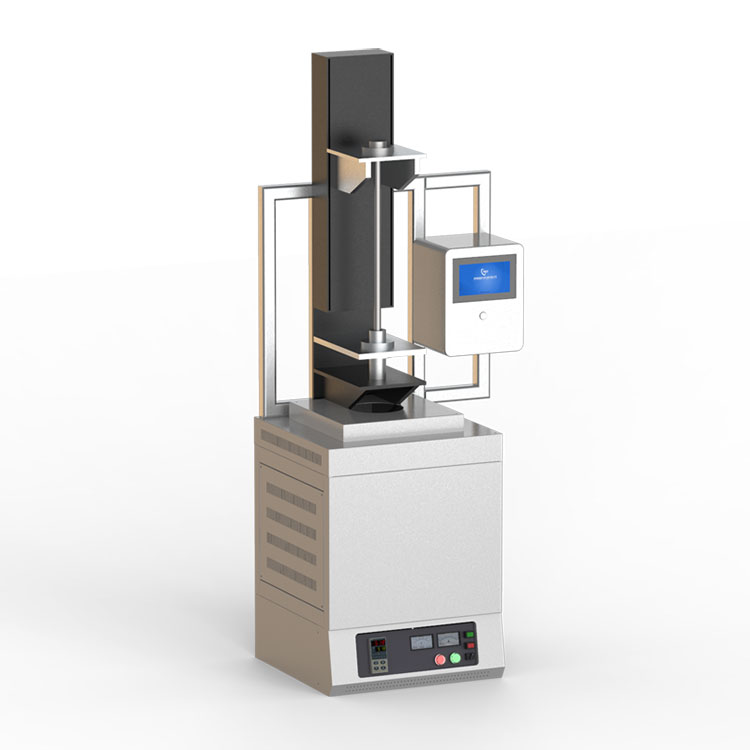

CY-1200-YB Wire Cutting Machine Swing Mechanism (especially suitable for cutting high-hardness materials such as gemstones, jade, etc., or low-hardness graphite, KDP, etc.) |

CY-1200-A Axis Swing Rotation Mechanism (especially suitable for cutting high-hardness materials such as jade, etc.) |

Heating Platform |

Silent Oil-free Air Compressor |

DX-100 Single Crystal Orientation Instrument |

Optional accessories | 600mm×700mm×1500mm |

Optional accessories | 约300kg |

Optional accessories | 1. Cutting size can reach 8". (max) 2. The main motor drives the diamond cutting wire to move downward at a constant speed, and the material is fixed on the workbench to ensure stable cutting. 3. The workbench can be rotated 360° manually or through program control. 4. The pneumatic tensioning system uses imported pneumatic components to make the tensioning force more stable and reliable. 5. The PLC program control system and large-size touch screen make the operation simple and fast. 6. Various tooling fixtures can be designed according to your needs. |

Functions and uses | Ceramic materials | Alumina ceramics, zinc oxide ceramics, zirconium oxide ceramics, target ceramics, honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc.; |

Crystal materials | Graphite, silicon crystals (solar polysilicon, single crystal silicon), sapphire, alumina crystals, infrared glass crystals, alumina crystals, silicon carbide crystals, cesium iodide crystals, etc. |

Glass materials | Chalcogenide glass, optical glass, quartz glass, infrared glass, glass tubes, etc. |

Metal materials | Metals and alloys such as iron, aluminum, copper, titanium alloy, magnesium alloy, non-ferrous metals (zinc sulfide, ferrite), etc. |

Composite materials | PVC boards, carbon fiber composites, glass fiber composites, etc. |

Rock materials | Precision cutting of natural rocks, jade, meteorites, Pei Cui, agate, etc., and precision slicing of various high-value materials; square slicing of geological light slices, geological thin slices (sedimentary rocks, igneous rocks, metamorphic rocks, ores), etc. |

Thermoelectric materials | Bismuth telluride, lead telluride, silicon-germanium alloy, etc. |

Infrared optical materials | Crystals such as zinc selenide, zinc sulfide, silicon, germanium, etc. |

Biomedical materials | Bioplasted specimen slicing (human and animal organs, combined slices of hard and soft tissues of the jaw, implant observation, dental crowns and bridges, and histological specimens such as teeth) ; Orthopedic soft and hard tissue sections (fresh and hard tissues such as femur, hip joint, vertebral body, bone histology samples with implants, etc.); Cardiovascular stent sections, stone sections and other medical tissue sections; |