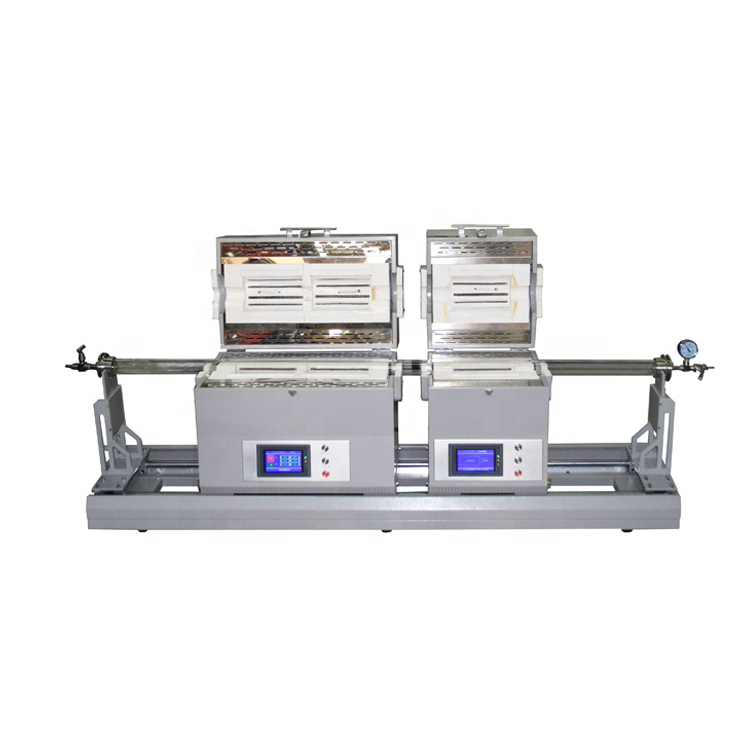

Furnace

Construction | Double layer steel casing with air cooling

High purity alumina fiber insulation for max. energy saving

Splitable cover for easy tube replacement |

Power

Consumption | 5 KW |

| Input Voltage | AC 208-240V Single Phase, 50 or 60 Hz |

Maximum

Temperature | 1200℃ |

Continuous

Temperature | 1100℃ |

Maximum

Heating Rate | <= 20℃ /min |

Heating Zone

Length | Three zones: (880mm, 35" in total)

Zone 1: 220mm (8.6" )

Zone 2: 440mm (17.3")

Zone 3: 220 mm (8.6") |

Constant

Temperature

Zone | If three zones are set at the same temperature, constant temperature zone

is 25"

(625 mm) long with a temperature discrepancy of +/- 1℃.

If using only one zone (center zone), constant temperature zone is 4.3"

(110 mm)

long with a temperature discrepancy of +/- 1℃. |

Temperature

Accuracy | +/- 1℃ |

Heating

Elements | Fe-Cr-Al Alloy doped by Mo |

Temperature

Controller | Three precision temperature controllers to control three zones separately.

PID automatic control with 30 programmable segments for precise control

of heating rate, cooling rate and dwell time.

Built in overheating & broken thermocouple protection.

Over temperature protection and alarm allows for operation without

attendant(s).

+/- 1 C temperature accuracy.

RS485 Communications Port.. |

Quartz Tube&

Sealing Flanges | 80 mm O.D x 72 mm ID. x 1400 mm fused quartz tube included.

Vacuum flanges with valves and pressure gauge are included.

Thermal block must be placed inside tube as the drawing below |

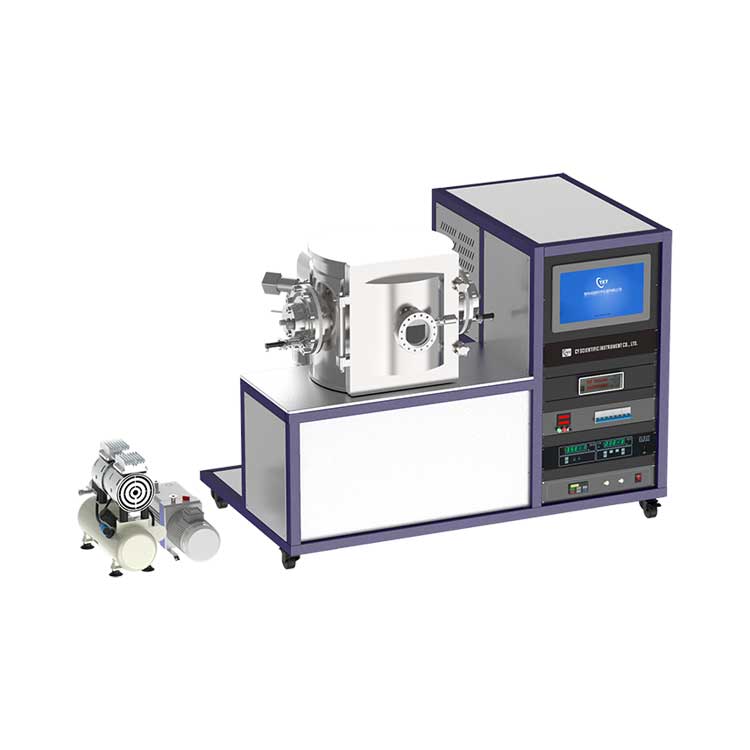

Vacuum Sealing

Flanges | Two stainless steel flanges with both vacuum gauge and valves included.

Min. vacuum pressure achieved by mechanical pump is 5.5 m-torr.

( 5.5x10^-3 torr).

The pressure can reach 10^-5 torr by using mechanical + molecular pump.

Leaking rate is < 5 m-torr / min. and stable vacuum pressure after 24 hours

is < 2 torr. |

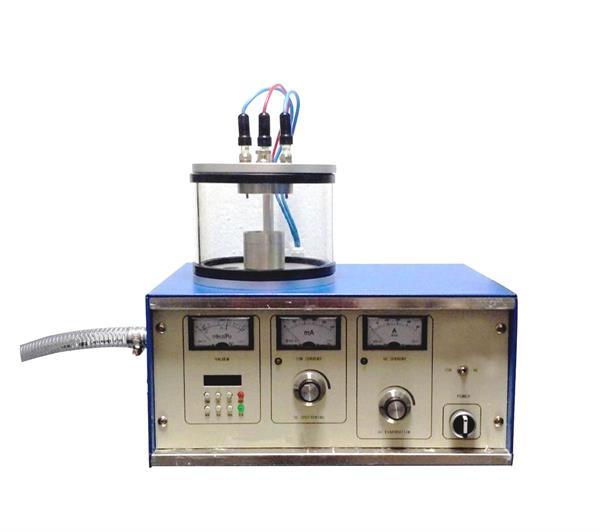

| Oxygen Monitoring | An Oxygen Sensor can be used to monitor the oxygen level of gas(es) used

in CVD systems

for preventing or reducing oxidation. Please click the picture below to

learn more: |

| Vacuum Pump | 120 L/m Rotary Vane Vacuum Pump is included with max. vacuum pressure

of 10^-2torr. Stainless steel hose tube is included for connecting to tube

furnace. |

Gas Flow Meter

and

Pressure Meter

| Three gas flow-meters (4% accuracy FS) are installed inside the mobile case

to

enable monitoring of gas flowing rates

Compact direct read flow meter, 10-100 cc/min.

Compact direct read flow meter, 16-160 cc/min.

Compact direct read flow meter, 25-250 cc/min. |

| Valves | Four stainless steel valves are installed in the side panel of mobile cart to

control mixing of three inlet gases separately |

| Dimensions | Furnace: 1100 X 450 x 670 mm

Bottom Mobile case: 600x600x597 mm |