Basic Info

Model NO.: CY-VTC-200P

Coating: Vacuum Coating

Condition: New

Chamber: Anti-Corrosive

Warranty: One Year

Transport Package: Wooden Box

Origin: Zhengzhou, China

Type: Powder Coating Booth

Substrate: Ceramic

Structure: Polypropylene

Motor: Brushless

Trademark: CY

Specification: chamber dia. 150mm

HS Code: 85141090

Product Description

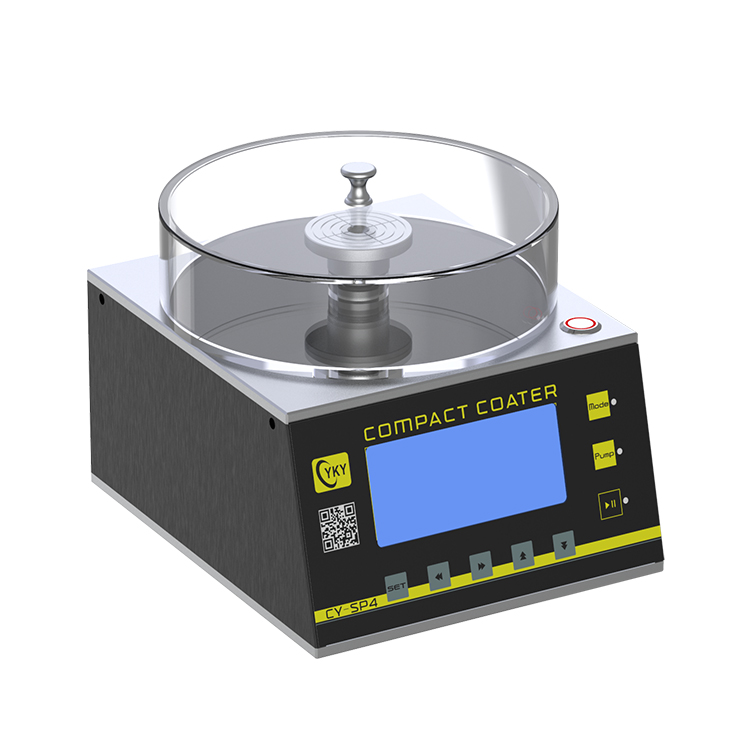

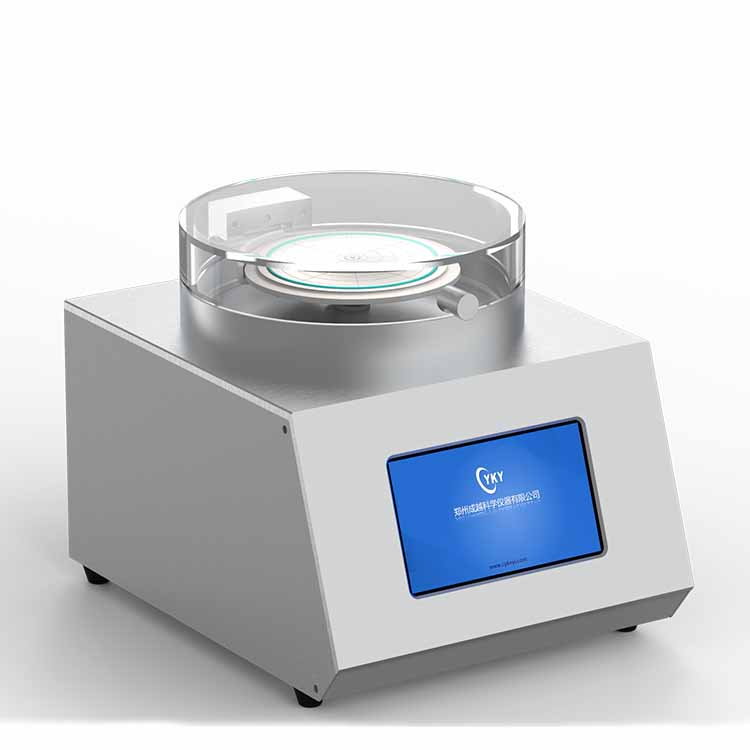

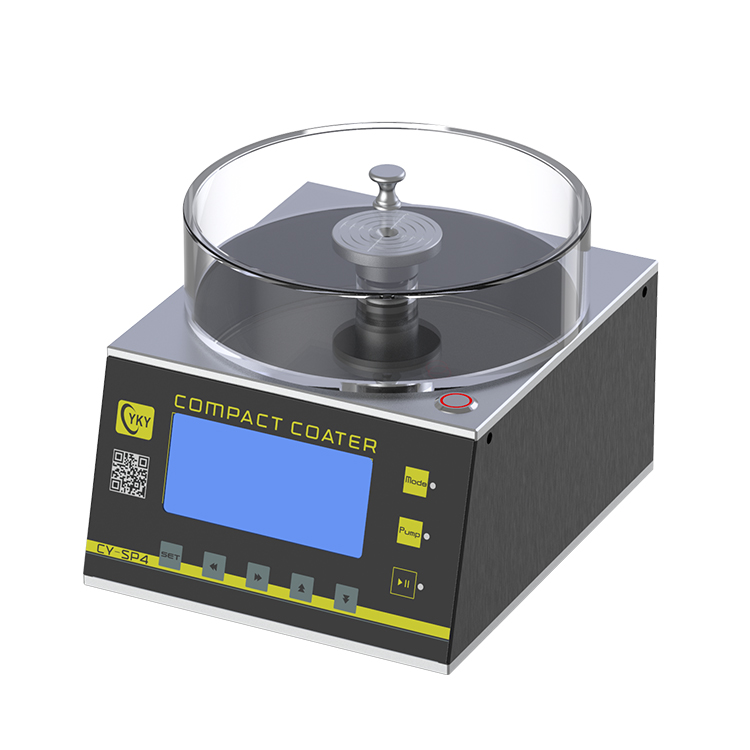

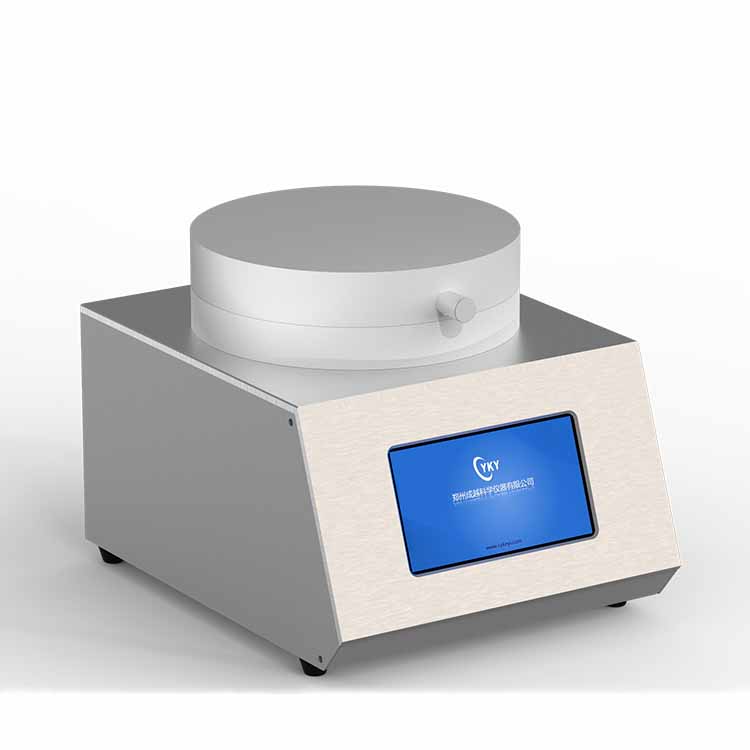

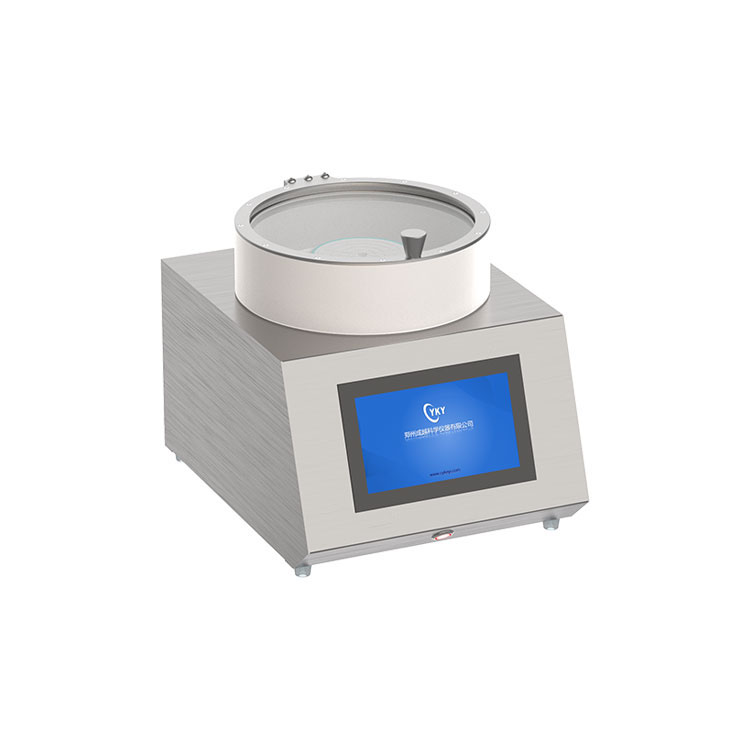

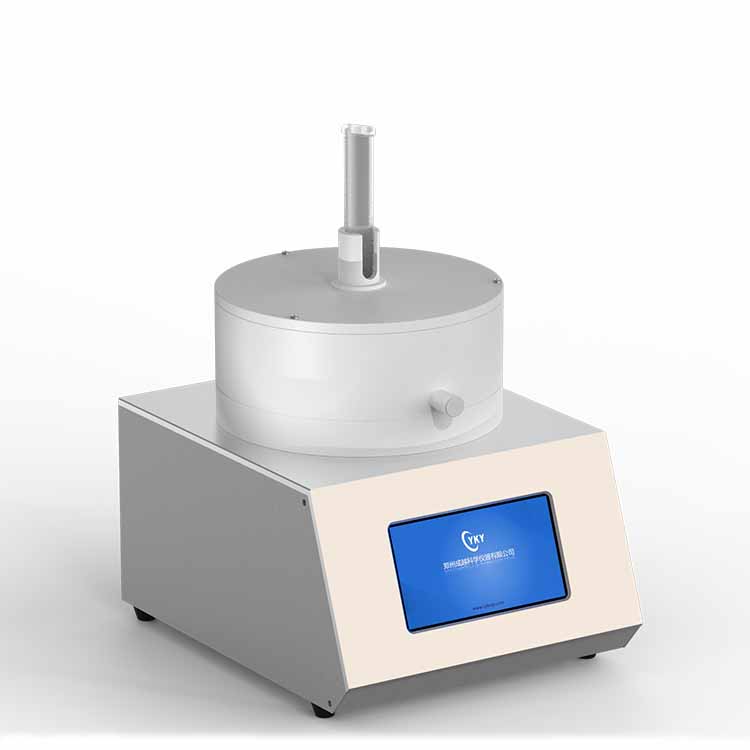

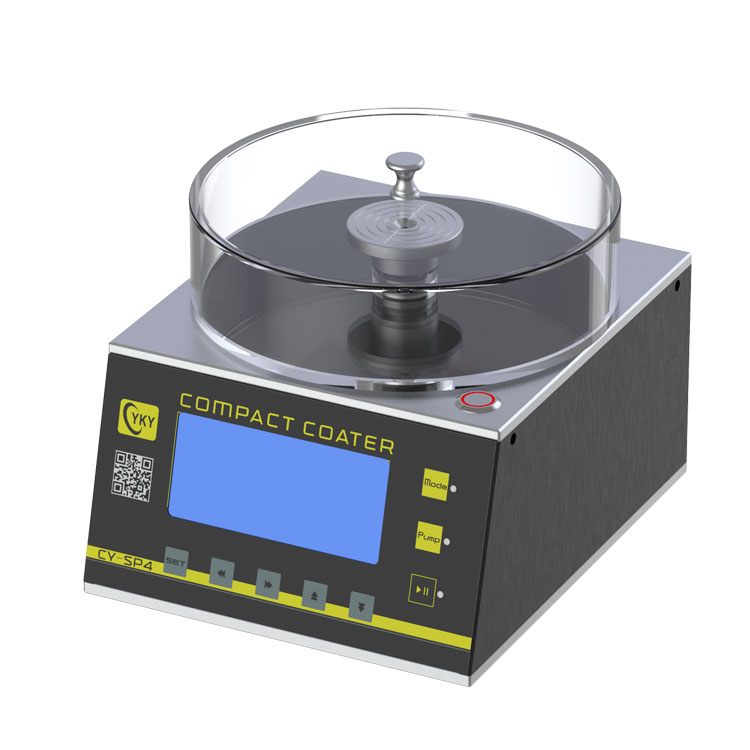

Anti-Corrosion Spin Coater ( 8000 RPM & 6" wafer Max.) with Complete Accessories

Introduction

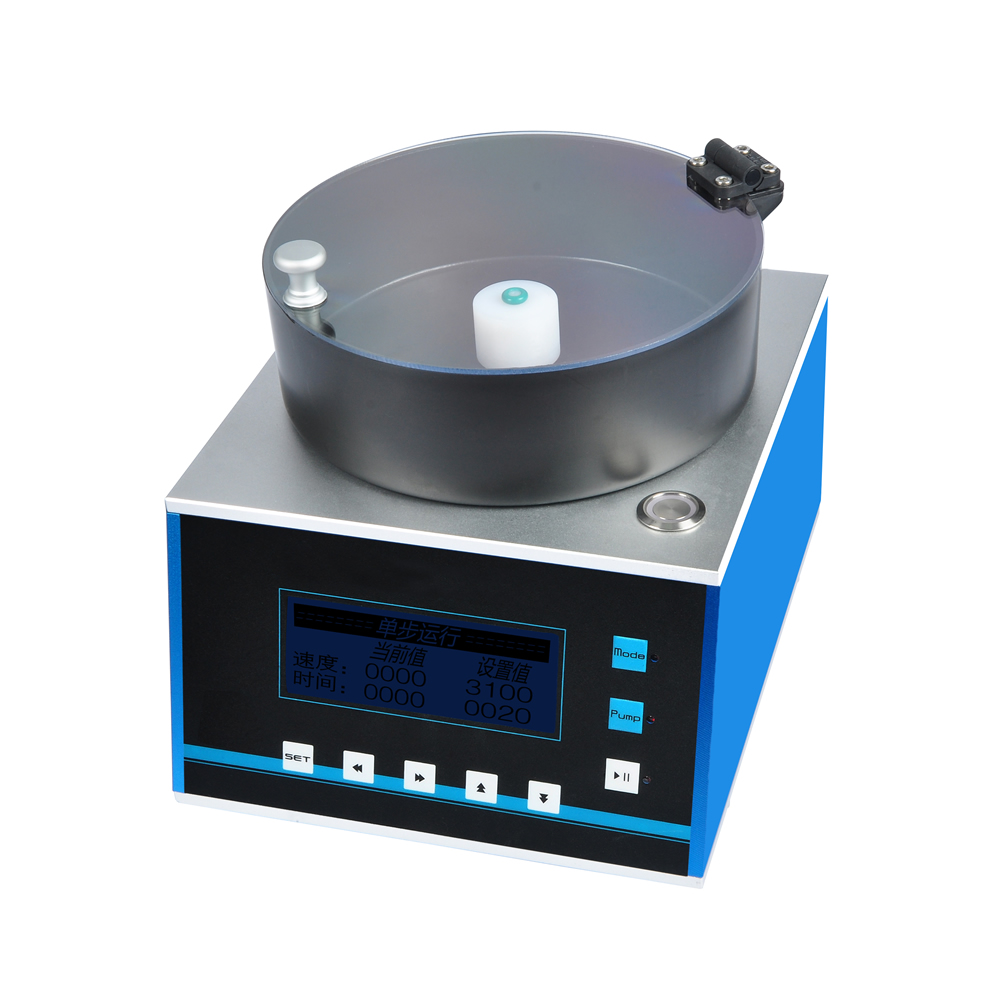

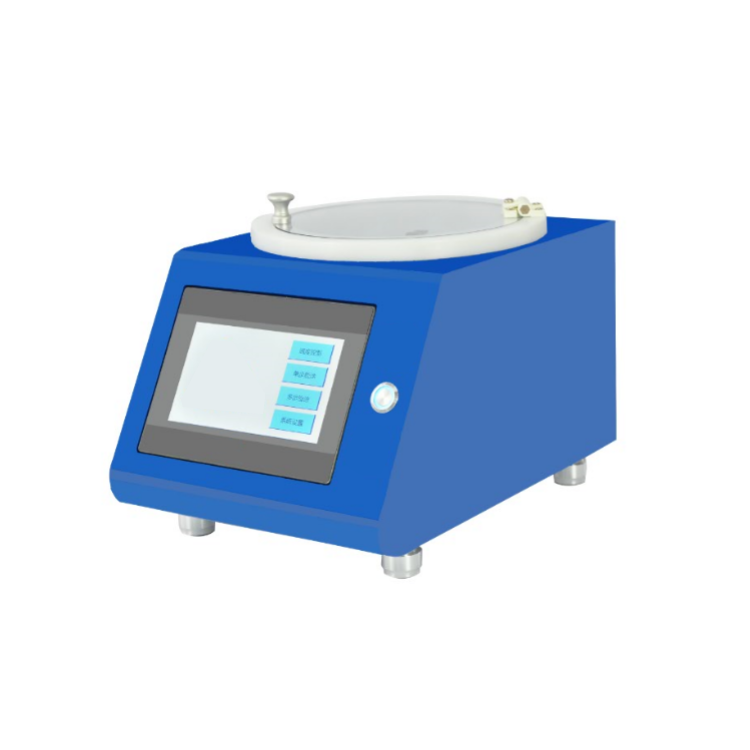

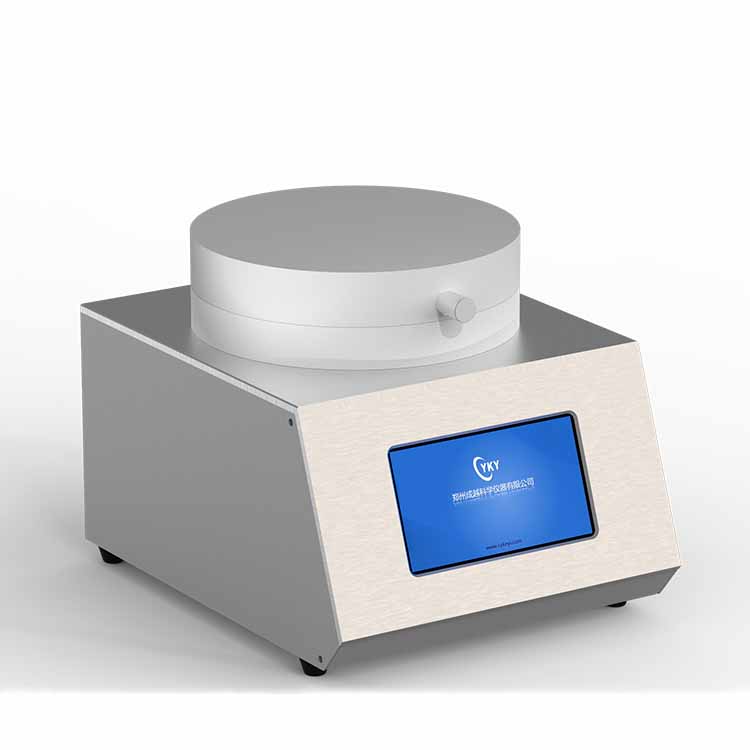

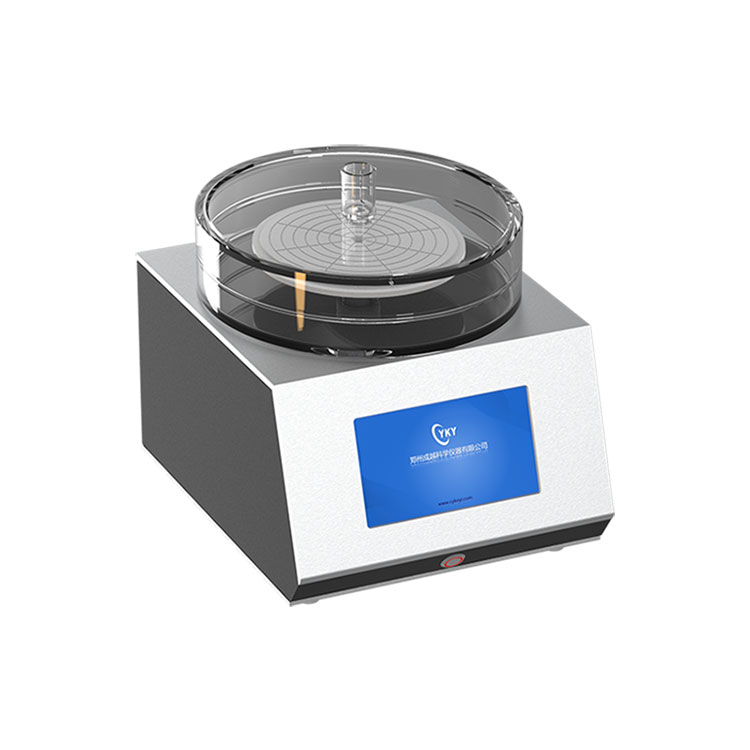

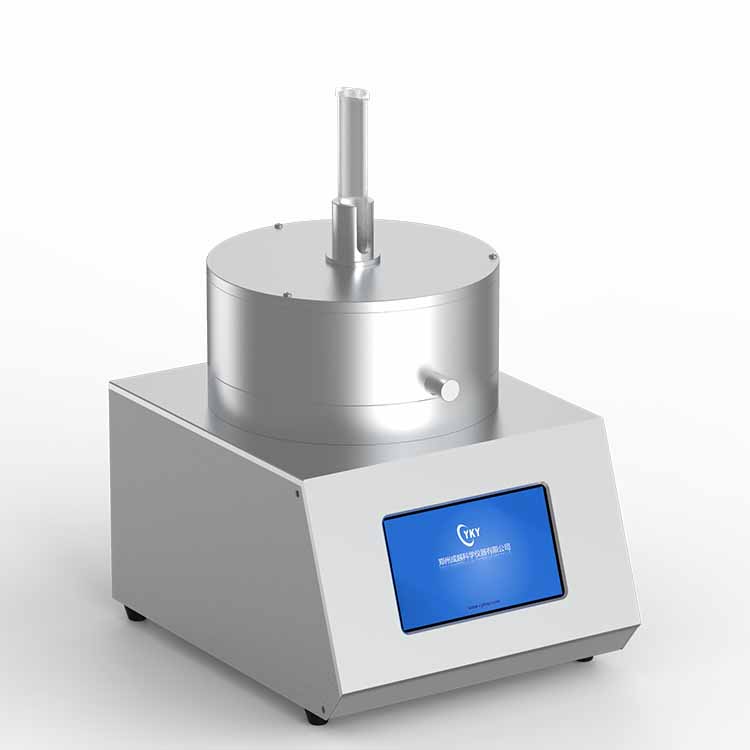

Anti-Corrosion Spin Coater is made of Polypropylene (PP) material, which can be used for strong acidic or alkali solution, especially suitable for use inside glovebox under Ar gas. Four vacuum chucks are included for coating wafer from 10 mm to 6". Digital control box is separated from spin coater which allow you operate in the remote location. The spinning speed is variable from 500-8000 rpm with two programmable segments. The package includes the oilless vacuum pump and 20ml syringe for immediate use.

Specification

Structure

| Case and spin disk made of PolypropylenePolypropylene (PP) to resist most of the corrosive solutions.

Digital control box is separated from spin coater.

One filter is included in standard package. It is used to connect the pump and coater for preventing waste water from flowing into the pump.

One oil-less vacuum pump is included in the standard package |

| Input Power | Default 220VAC, 50/60Hz, single phase, 1000W Max.

110V is available in optional bar ( with 1500W transformer )

A power socket on the back of the Digital control box is used to supply power for the vacuum pump. (The output voltage of this power socket depends on the input voltage of the spin coater, e.g. if the spin coater is plugged into AC 110V, this power socket will supply AC 110V.) |

| Chamber &Vacuum Chuck | Chamber diameter: 150 mm

4 sets of PP anti-corrosive vacuum chucks with different sizes ( Φ21mm,Φ38mm,Φ60mm,Φ100mm ), which can hold substrate from 10mm Dia to 6" Dia.

If your sample < 10 mm, please order rubber cup from us at extra cost |

Spin Speed | Digital control panel with two programmable segments of different spin times and speeds

500 - 8000 RPM adjustable spinning speed at each segment |

| Liquid Injecting | 20mL syringe is included to contain the coating material.

Optional:

You may choose Precision Electronic Single Channel Pipette: 20 - 200uL for more accurate coating

Using plasma cleaner to treat substrate surface before coating can improve film quality

You may consider our new product: Heatable syringe

|

| Motor | 24VDC, Brushless, 200W max.: |

Product Dimensions

| Spin Coater: 25.2cm(Φ) x 41cm(H)

Digital controller: 23cm(L) x32cm(W) x16cm(H) |

| Net Weight | 25 kg |

| Compliance | CE Certified |

| Warranty | One year limited with lifetime support |

Service

1. Factory prices with the best quality.

2. One year free-of-charge maintenance for all the dental equipment

3. Customized service for special demand

4. Fast and flexible delivery, by sea, by air, by express

5. Quick response within 24 hours

How to order

1. If you are interested in our products, please tell us the model number and quantity.

2. We will make a proforma invoice for your order.

3. We will deliver the product ASAP on receipt of the payment

Guarantee

1. Guarantee for one year after shipment.

Payment

1. Western Union

2. PayPal

3. Secure Payment through Alibaba

4. Telegraphic transfer

5. L/C

Factory

Zhengzhou CY Scientific Instrument Co., Ltd is mainly engaged in the research and development, design, manufacturing and sales of equipment used in scientific researches. Independence and innovation is the company's tenet.Our main products include: tube furnace, muffle furnace, plasma cleaner, vacuum furnace, atmosphere furnace,CVD system and customized lab equipment.Welcome you come to visit us.

Exhibition