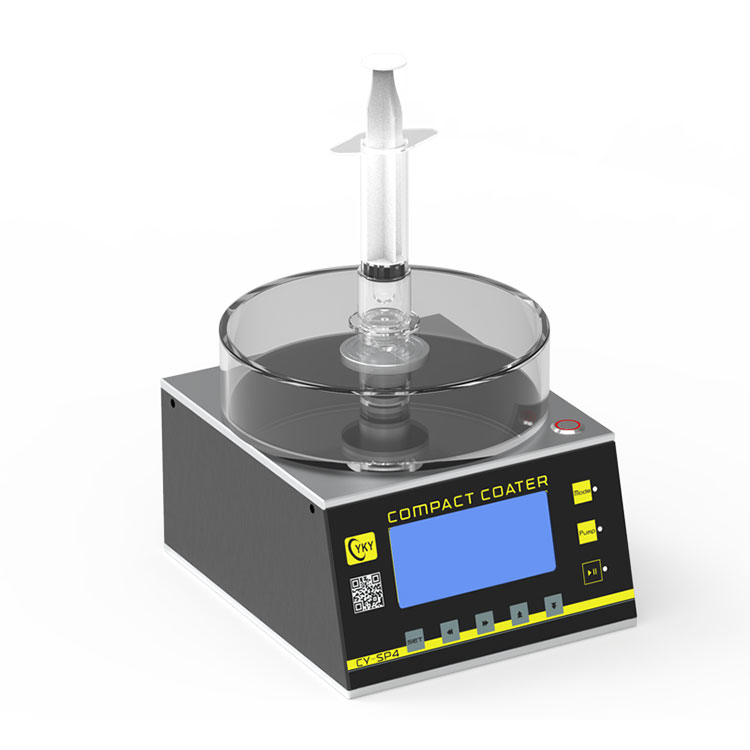

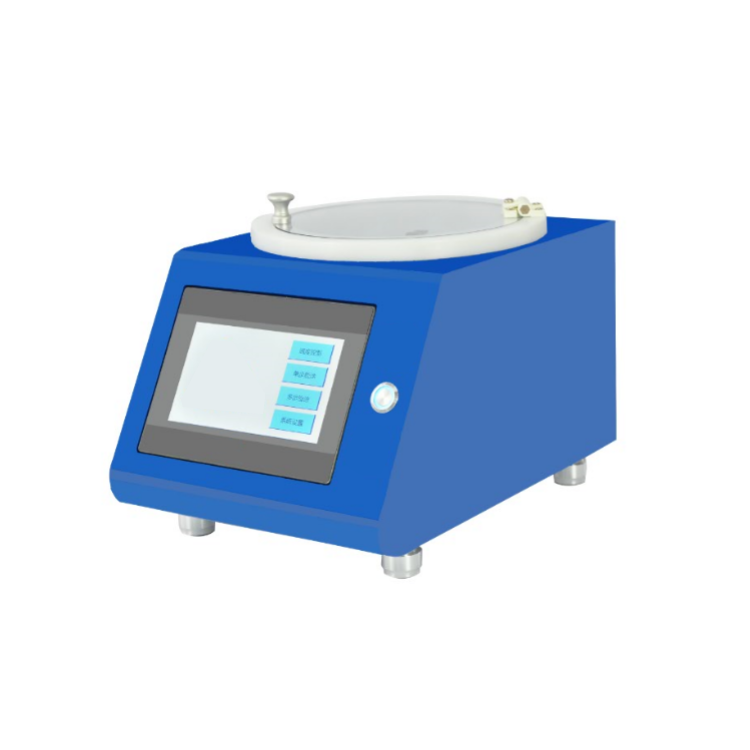

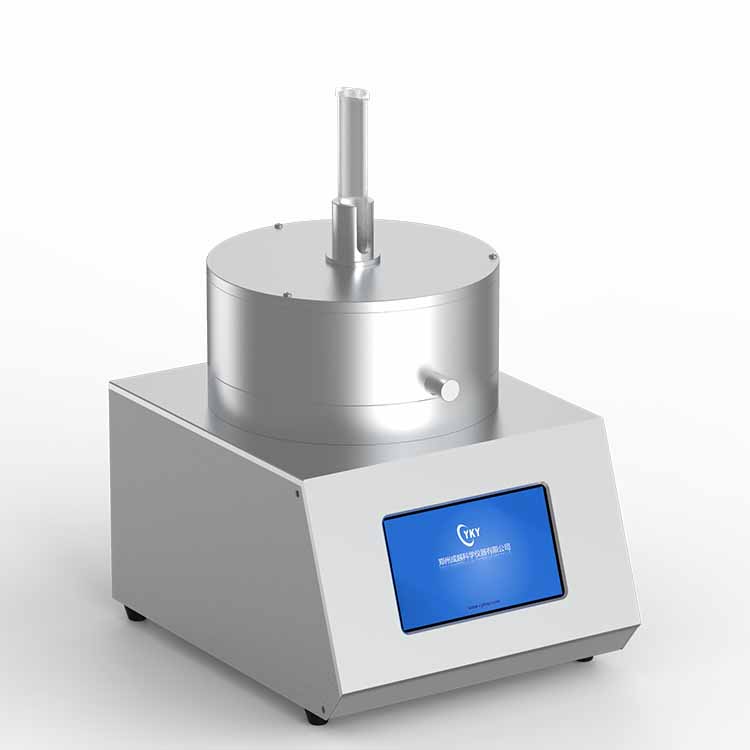

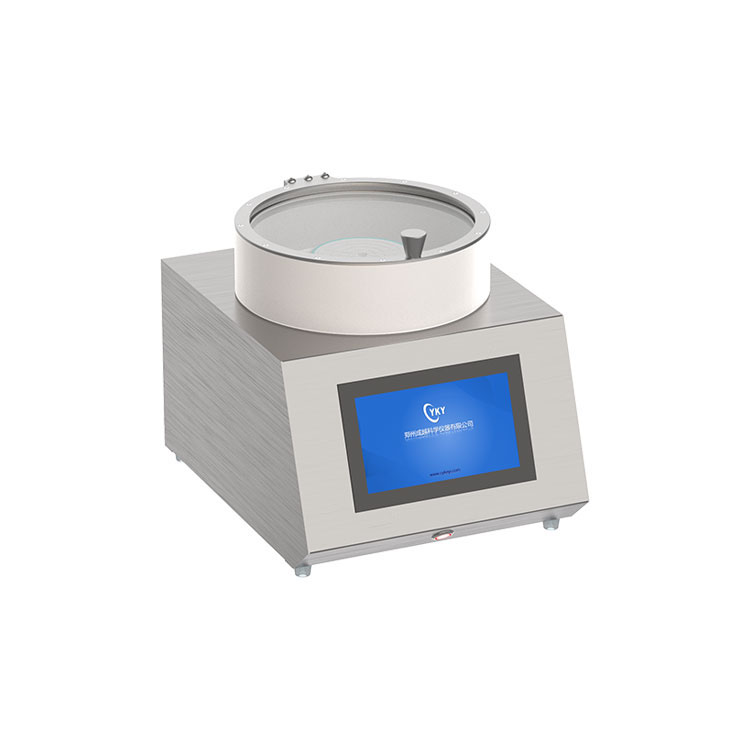

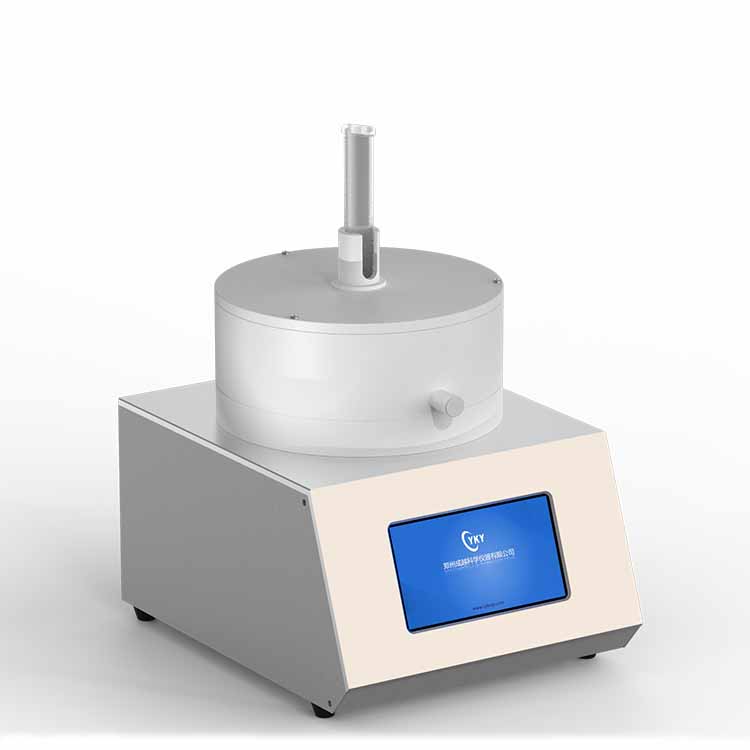

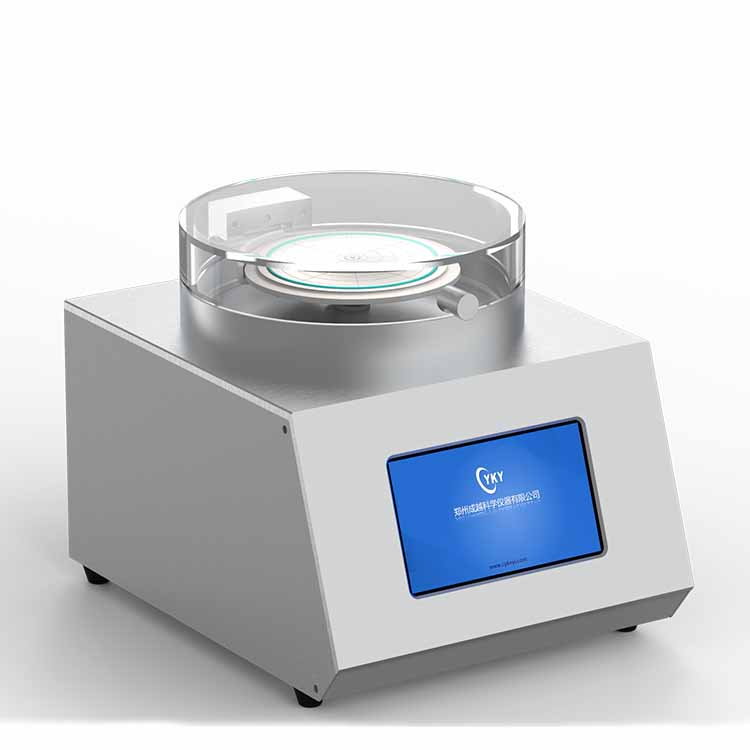

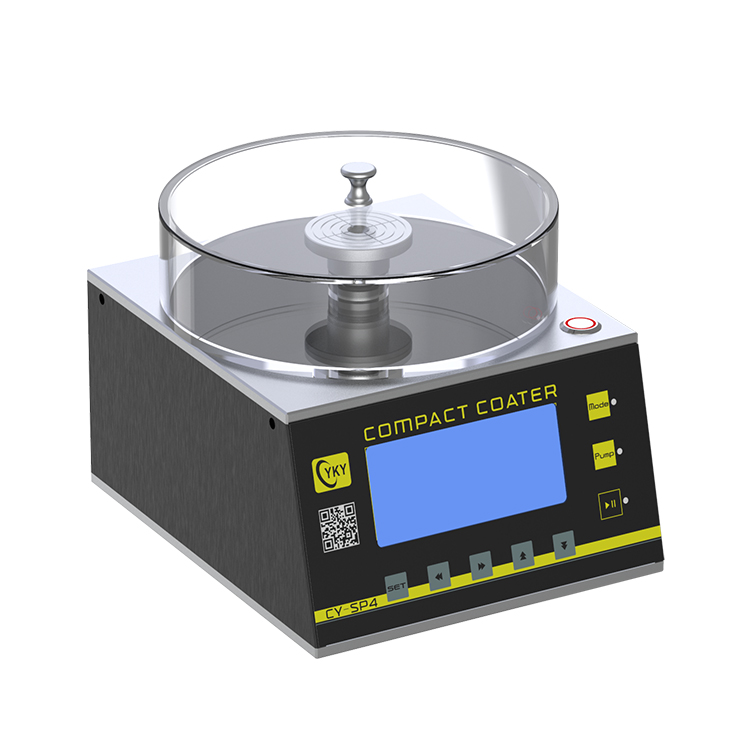

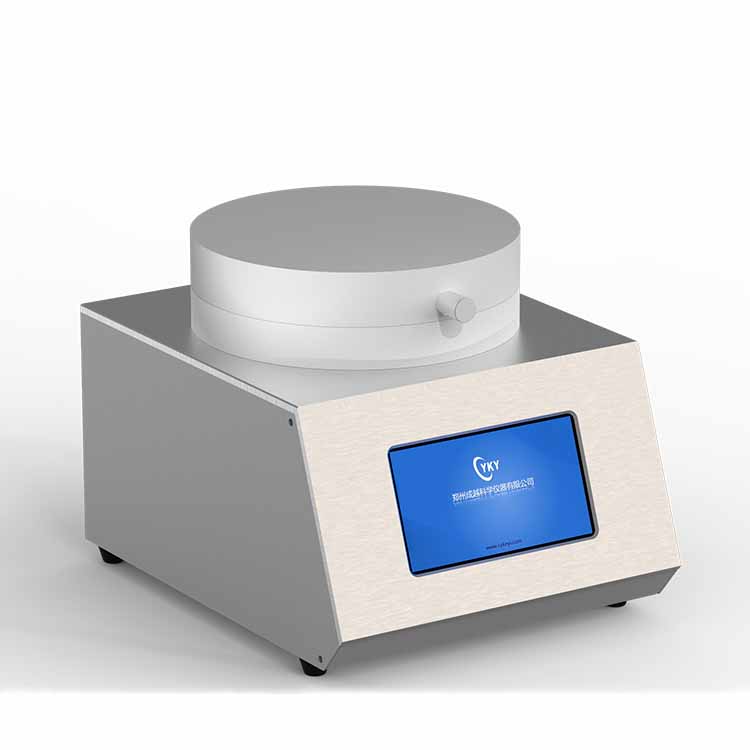

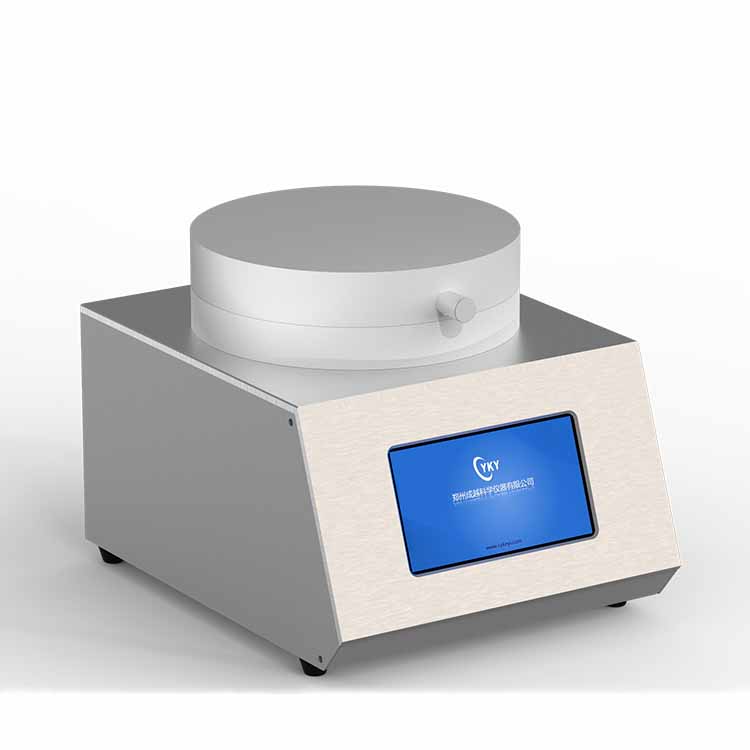

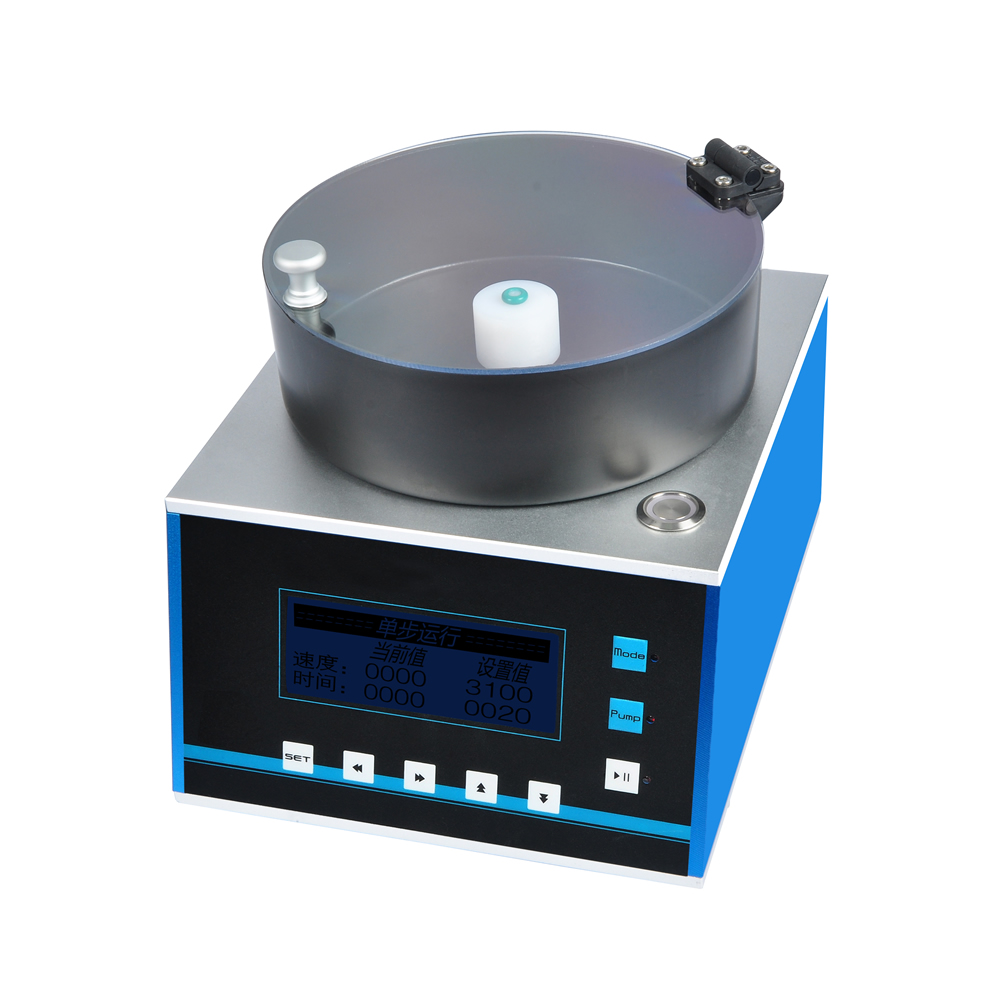

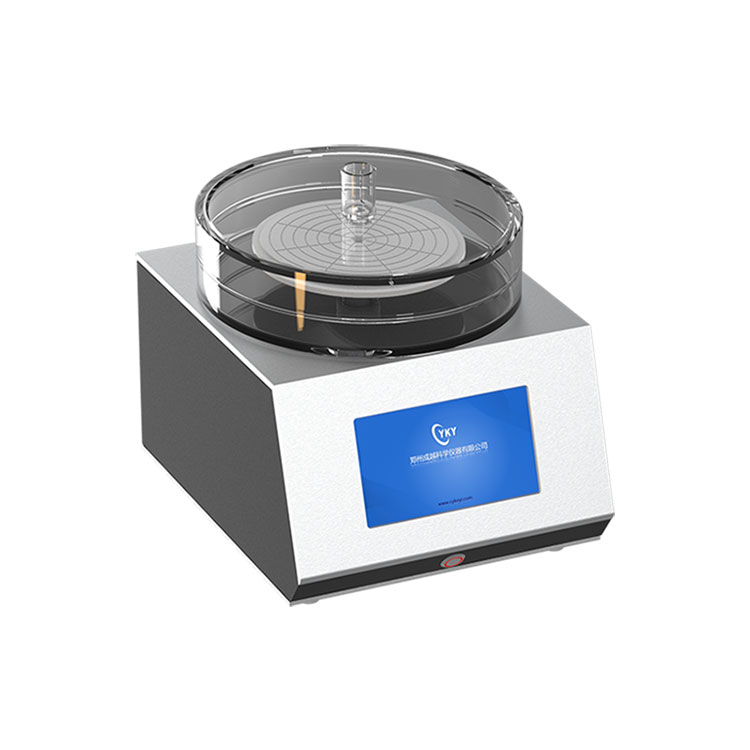

The vacuum heating type spin coater mainly uses the centrifugal coating principle to coat a liquid or colloidal material on the substrate such as silicon wafer, crystal, quartz, ceramic and so on to form a thin film, and the film has a wide application in the field of material research. The working chamber of the heating type spin coater is made of polytetrafluoroethylene (plastic king) material, which is a polymer compound formed by polymerization of tetrafluoroethylene, which has excellent chemical stability and strong corrosion resistance. It is widely used in a variety of applications requiring acid and alkali resistance and organic solvents.

Vacuum heating type spin coater product features:

1. The surface of the coating can be heated at a constant temperature. The heating range is from room temperature to 120 °C, and the temperature control precision is 0.1 °C.

2. It can be used to uniformly coat organic matter for film preparation.

3. You can first be spin coating, and then bak it.

4. Rotating coating process parameters for a variety of different substrates can be stored. Each coating process can be set up with multiple different rotational speeds.

5. The working chamber is made of polypropylene (PP) material.

Vacuum heating type spin coater technical parameters:

Item | Detals |

rotating speed | 0~10000rpm |

accelerated speed | 100~5000rpm/s |

Speed resolution | 1rpm |

Single step time | 3000s |

Voltage input | AC220V 50Hz |