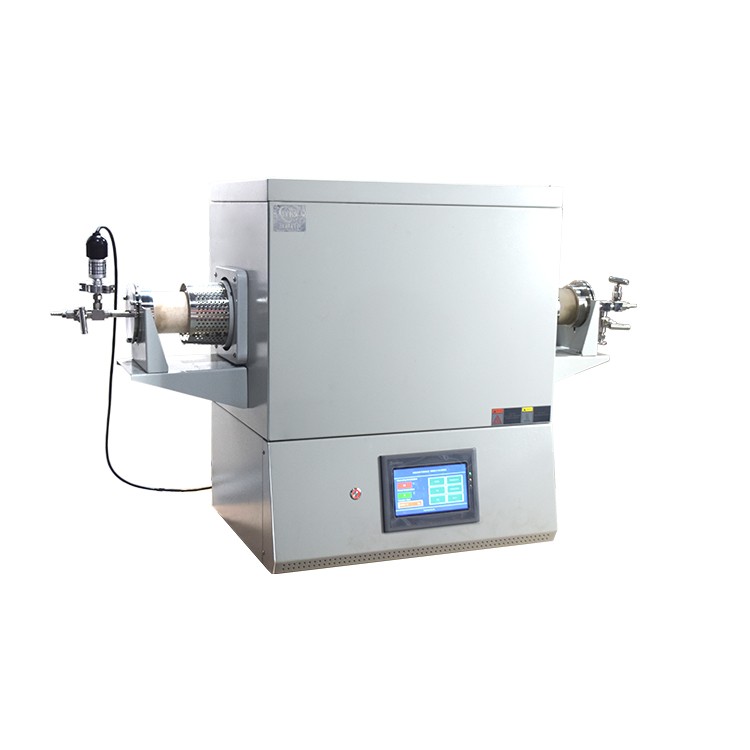

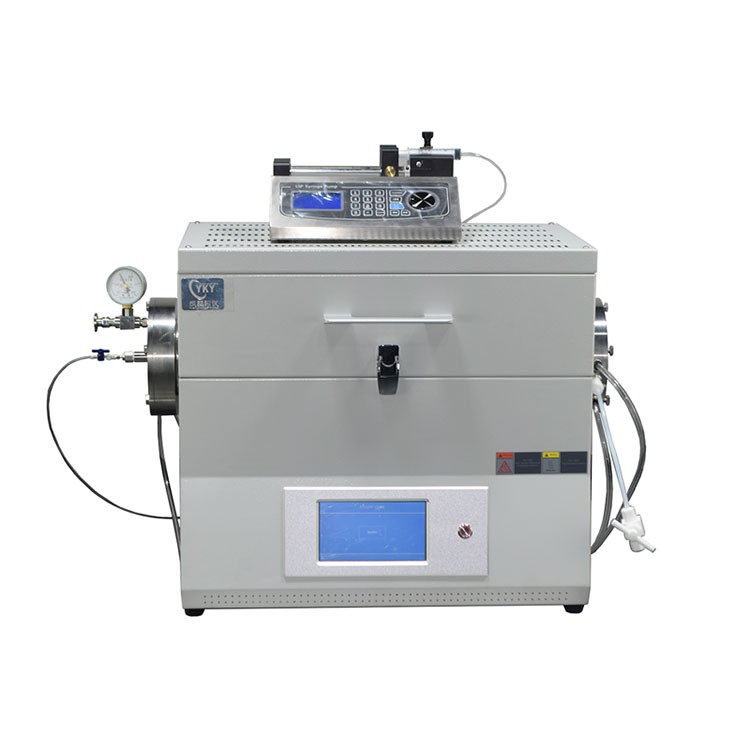

Furnace & Power | Splitable Eight heating zone tube furnace with air cooling layer High quality fibrous insulation and reflective coating for max. energy saving. Power: 208 - 240VAC 50/60Hz, Single Phase, 12 W max. (circuit breaker which is rated @ 80amps or higher is recommended) |

Heating Zone | Ten heating zones: 150mm / zone Total heating zone length: 1500mm Constant temp. zone: 900mm ±5°C |

Working Temperature | 1100°C max.for < 1hr 1000°C for continuous Heating rate: ≤10°C/min |

Temperature Control | Ten digital temperature controllers to controll each heating zone Each channel is with PID auto-tunning, upto 30 segments programmable Built in overheating & thermocouple failure protection. +/- 1 ºC temperature accuracy. |

Heating & Cooling Rate | Heating: 0-200℃ ≤10℃/min , 200-700℃ ≤6℃/min, 700 -900℃ ≤3℃/min, 900-1100℃≤1℃/min Cooling: 200-800℃ ≤10℃/min , 800-1100℃ ≤5℃/min |

Thermocouple

| Omega 3mm OD K Type with high-temperature (220°C) connector Total 10 TCs, one for each zone |

Process Vessel

| Pressure vessel is made of Nickel based superalloy GH747 Vessel size: OD 85 x ID 45 x Length 2400 (mm) |

Working Pressure

| 15 Mpa max. at <800°C 10 Mpa max. at <900°C 6 Mpa max. at <1000°C 4 Mpa max. at <1100°C Never heat up above 1200°C |

Working Gases

| Inert gas and oxygen No hydrogen or any flammable gas |

Flange and Fitting | Two CF type flanges are weld with female 1/4"NPT fitting to connect high-pressure tube 2 pcs Copper o-rings are included ( spare copper O-ring is available as consumable ) |

Gas Flow & Pressure Control System

| Gas flow and pressure control system is built in the separated unit with digital display Two pressure sensors and digital displays are installed to monitor the pressure for gas inlet and furnace tube One high-pressure mass flow controller is installed at the gas outlet to control gas flow rate with max. 10Mpa working pressure and 500 SCCM flow rate Pressure relief valves are installed to ensure safety. The valve will release gas when pressure reaches setting point. |

Dimension & Weight | Dimension: 26000mmL*700mmW*947mmH (furnace); 1100mmL*600W*1200mmH (control consol) Net weight: 480 kg |