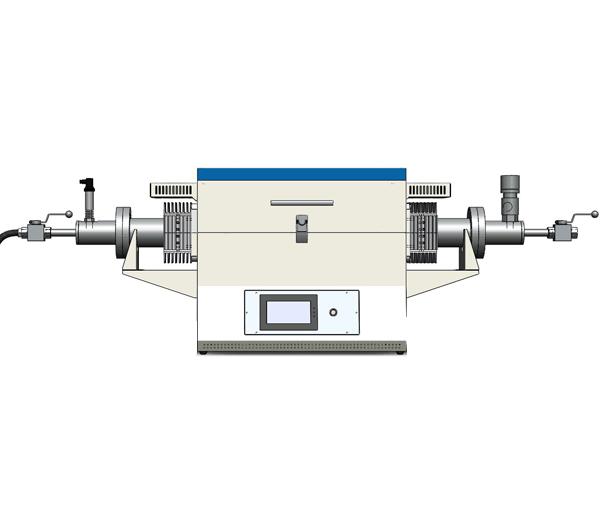

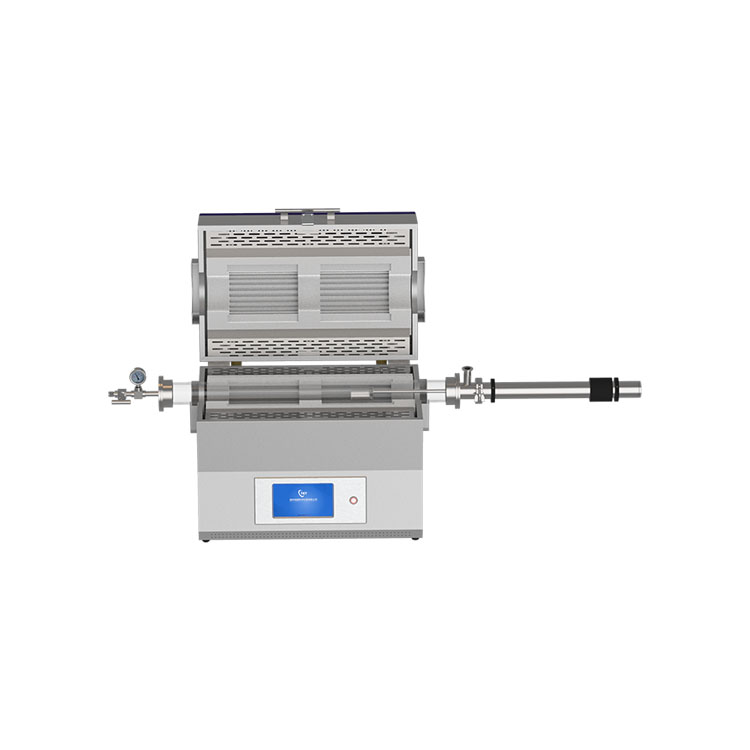

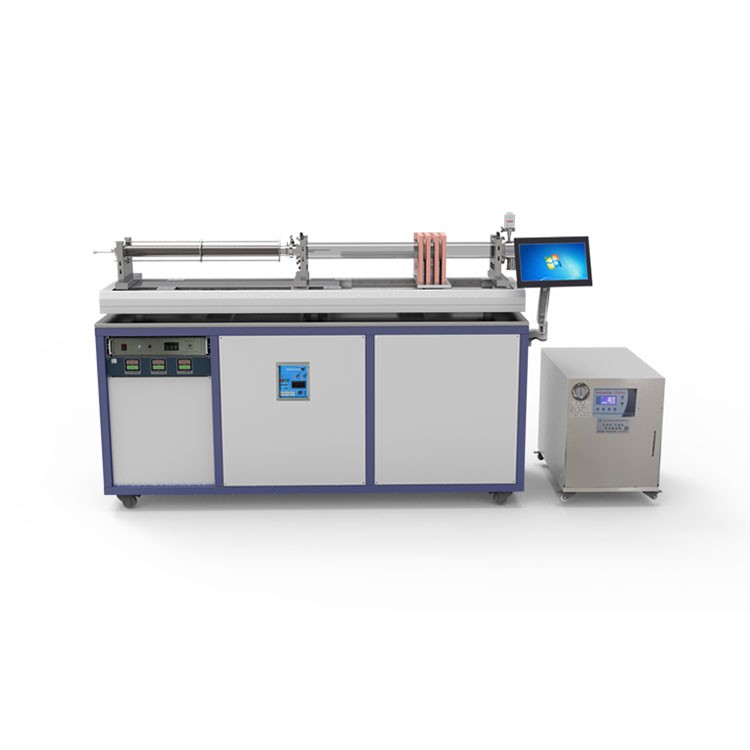

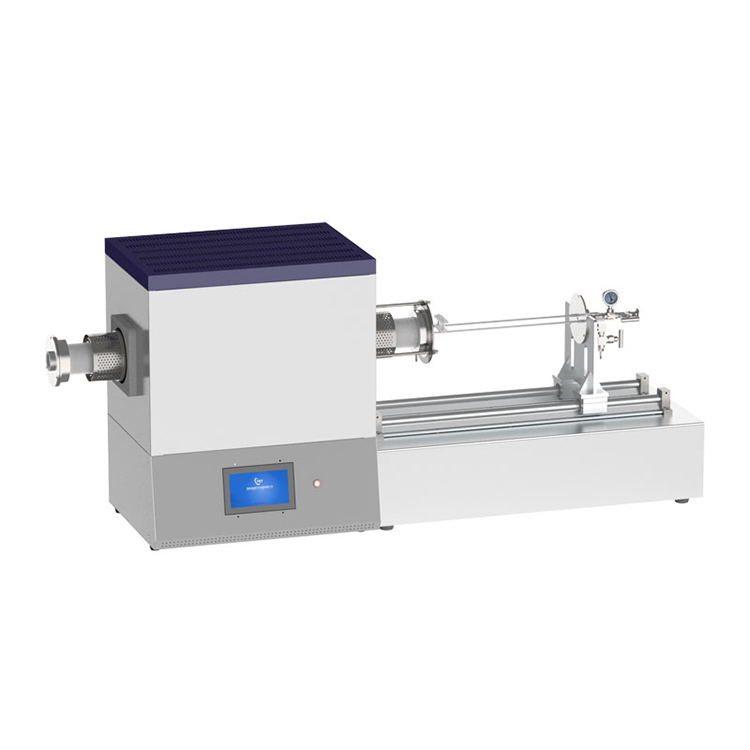

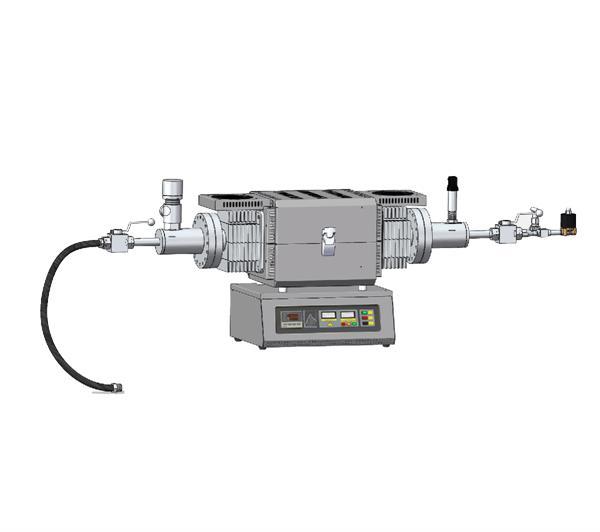

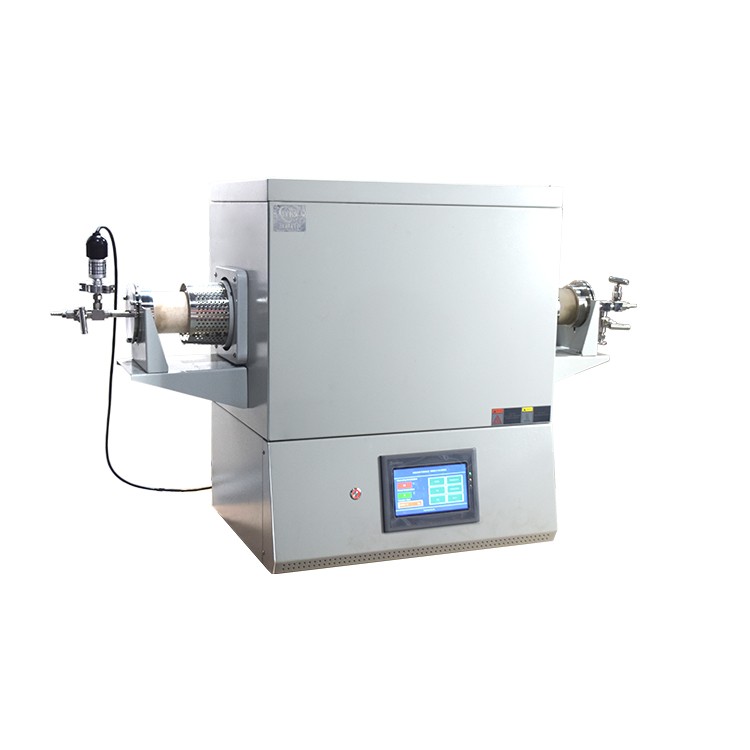

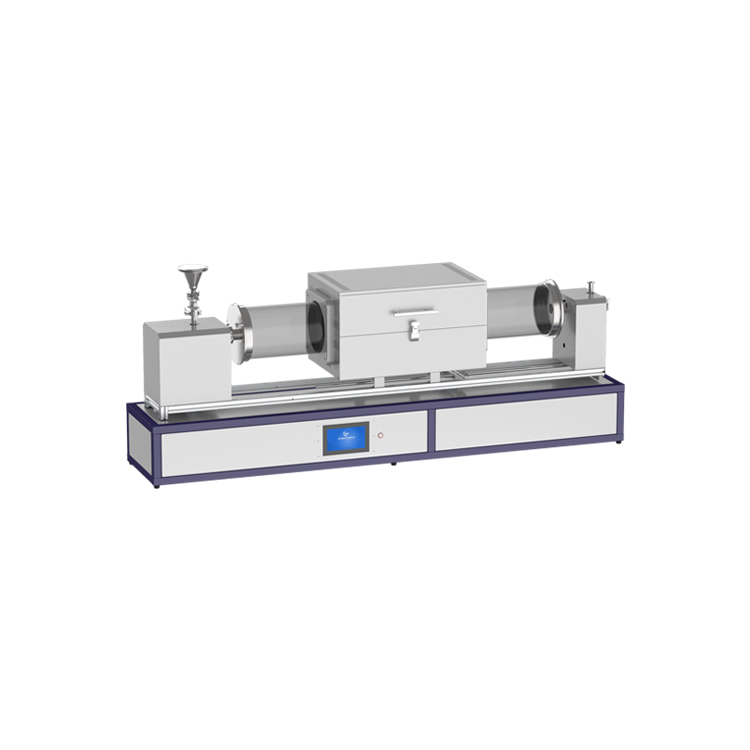

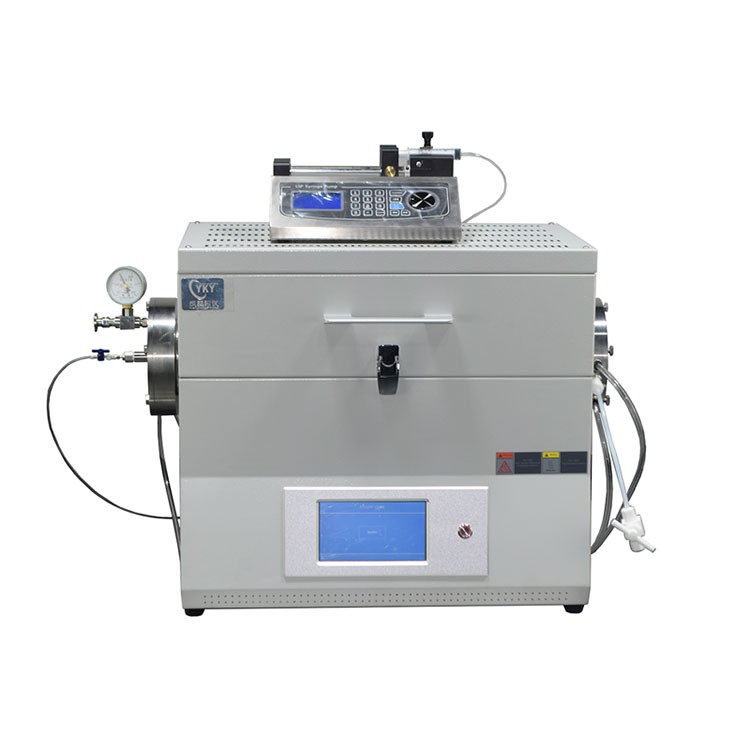

Furnace Construction | Double shell casing with cooling fans High purity alumina fibrous insulation for max. energy saving Split cover enables faster cooling and easy operation Hydrogen detector and solenoid valve are included for safety measures The liquid evaporator is heatable with a precision temperature controller to produce a mixing of hydrogen and liquid vapor. The hydrogen gas furnace must be placed under a fume hood which is not included. |

Power | 4 KW Max |

Input Voltage | AC 208 - 240V single phase (30A air breaker is required) |

Heating Elements | FeCr27Al7MO2 |

Heating Zone Length | Two heating zones: 8" (200 mm) length of each zone, 16" (400 mm) total Constant temperature zone: 150 mm within +/- 1℃ when two zones are set at same temperature |

Temperature Uniformity | +/- 1°C in heating Zone |

Continuous Working Temperature | 1100°C |

Recommended Heating Rate | 10°C /min |

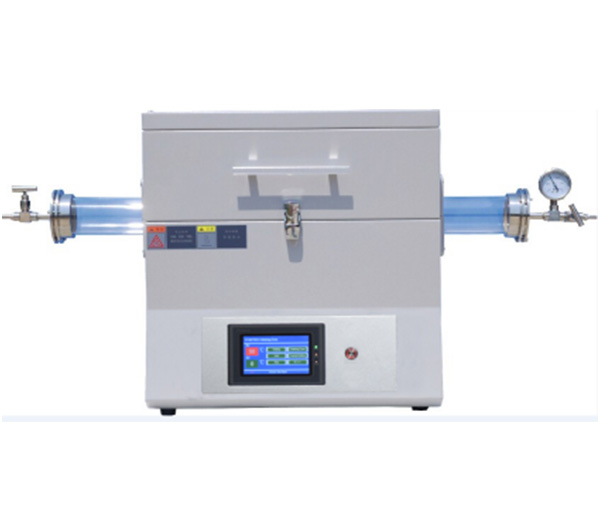

Processing Tube and Flanges | High purity quartz tube: Φ 80 (OD) × Φ 74 (ID) ×1000 L, mm Vacuum flange: SS304 flanges are included to achieve vacuum up to 10^ - 5 torr by turbopump. |

Temperature Controllers | Two MET certified digital temperature controllers with 30 programmable segments for precise control of heating rate, cooling rate and dwell time. Built in PID Auto-Tune function with overheating & broken thermocouple protection. Over temperature protection and alarm allows for operation without attendant(s). +/- 1 ºC temperature accuracy. RS485 port is installed in front of panel for PC connection PC control module and software is included for computerized temperature control. |

Float Flow Meter | Two flowmeters 50-500ml/min are built on the gas inlets. One flowmeter is for Hydrogen delivery while the other is mainly for CVD gas with liquid vapor The extra flowmeter is available upon request at extra cost. You may consider using our mass flow gas station 1 - 9 channel for more accurate gas control |

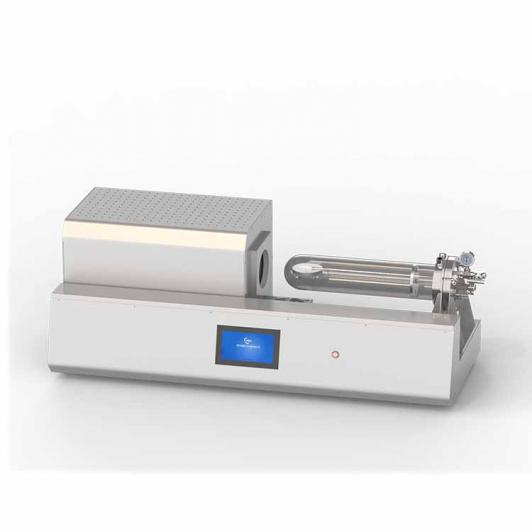

Bubbler/ Liquid Evaporator

| Such a liquid evaporator is suitable for liquid sources and chemical precursors delivery in CVD processes. One stainless steel container is included with capacity of 600 ml ( 80OD x 200H, mm) The container is inserted into a small cylindrical heater with thermal insulation The container can be heated up to 250°C and controlled by a precision programmable temperature controller. Two SS needle valves and one pressure gauge are built on the container |

Humidity Monitor ( included) | One precision humidity monitor is connected to the processing tube flange with KF25 adaptor Measurement range : 0 - 100 % RH with 1.5 % FS accuracy, or -60º ~ +60º DP with +/-0.3º accuracy. Tips: You may adjust the evaporator's (water inside) temperature and H2 gas flow rate to achieve desired humidity level. |

Hydrogen Detector System

(included) | Working Temperature Range: 40ºF to + 149ºF (- 40 ºC to + 65ºC) Alarm Point: H2 Limited Explosive Line 10 % (10 % LEL). Once detecting H2 gas beyond the point, it will shut off the inlet valve to the H2 automatically. |

Warranty | One-year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty). |

Furnace Dimensions | 1400 × 600 × 1200 mm |

Product Net Weight | 100 Kg |

Warning

| Tube furnaces with alumina tubes are designed for using under vacuum and low pressure < 0.12 atm (absolute pressure) The flow rate for gasses should be limited to < 200 SCCM (or 200 ml/min) for reducing thermal shocks to the tube Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°C |