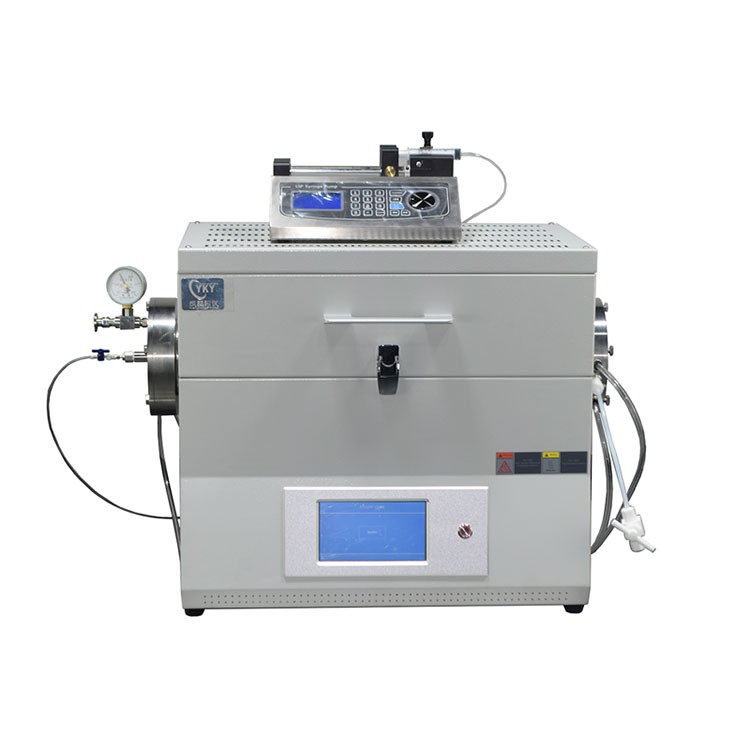

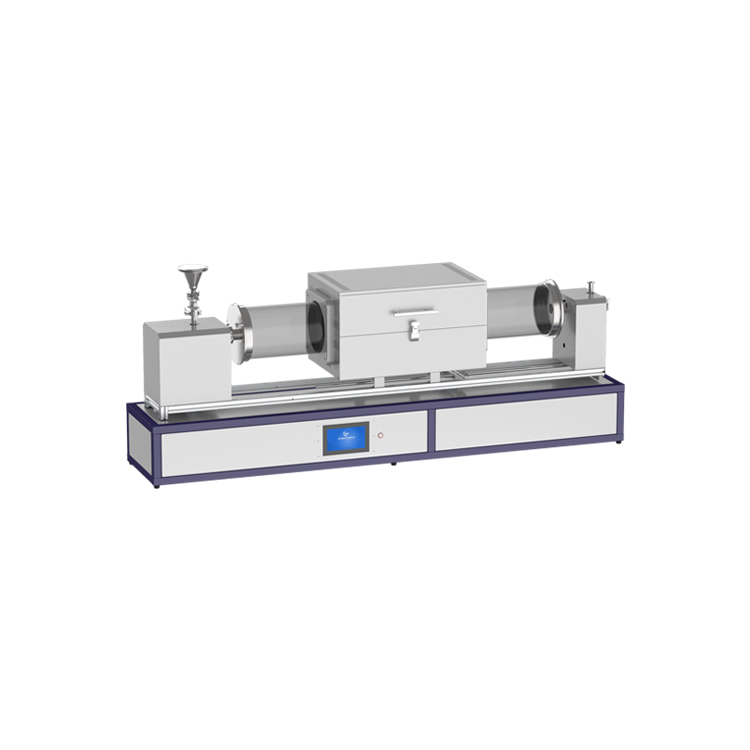

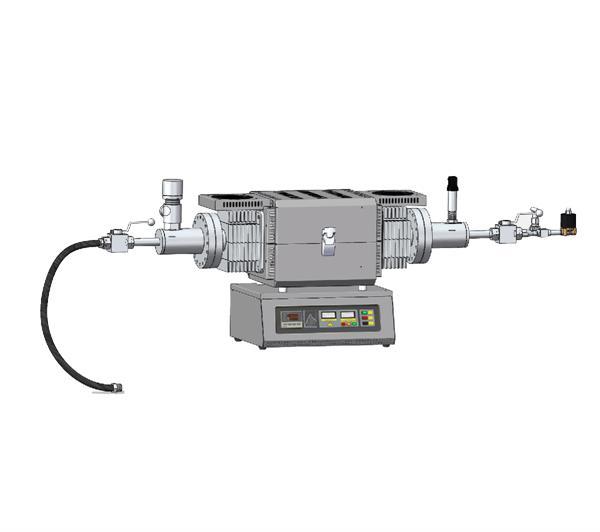

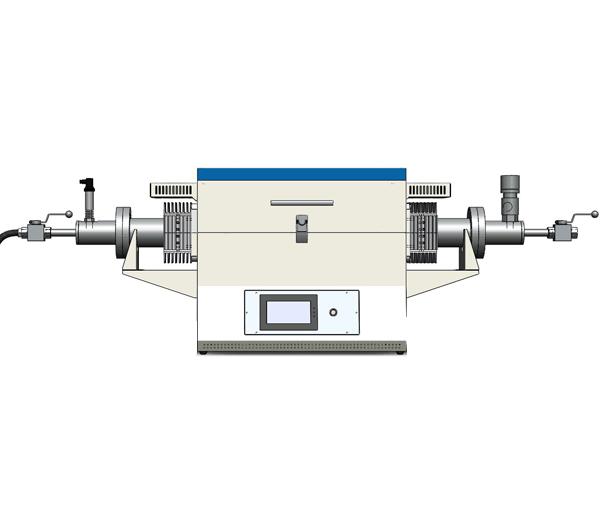

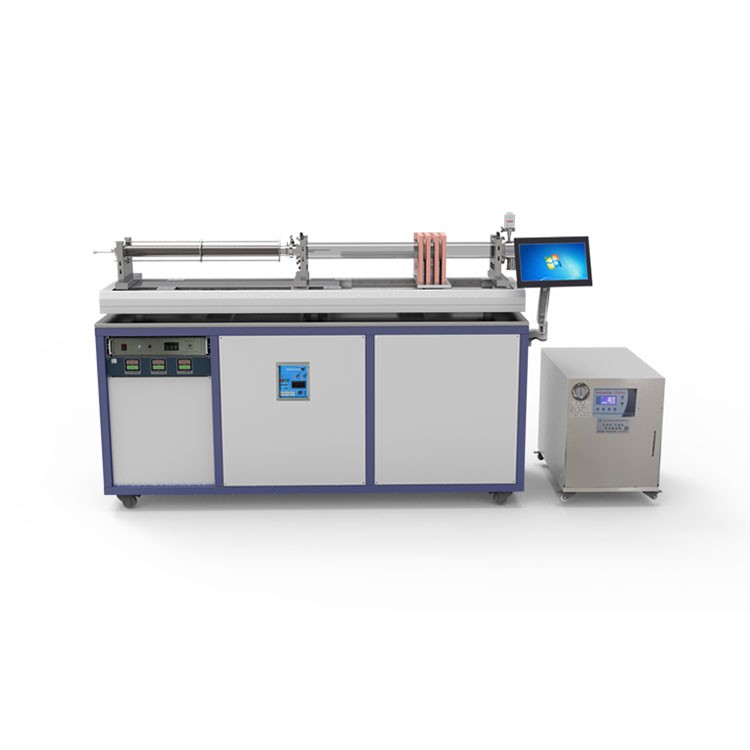

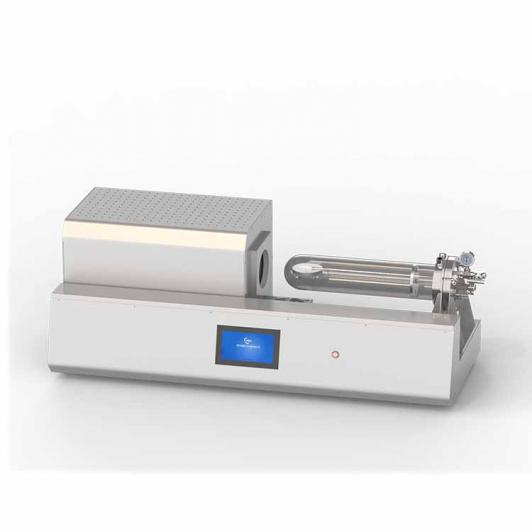

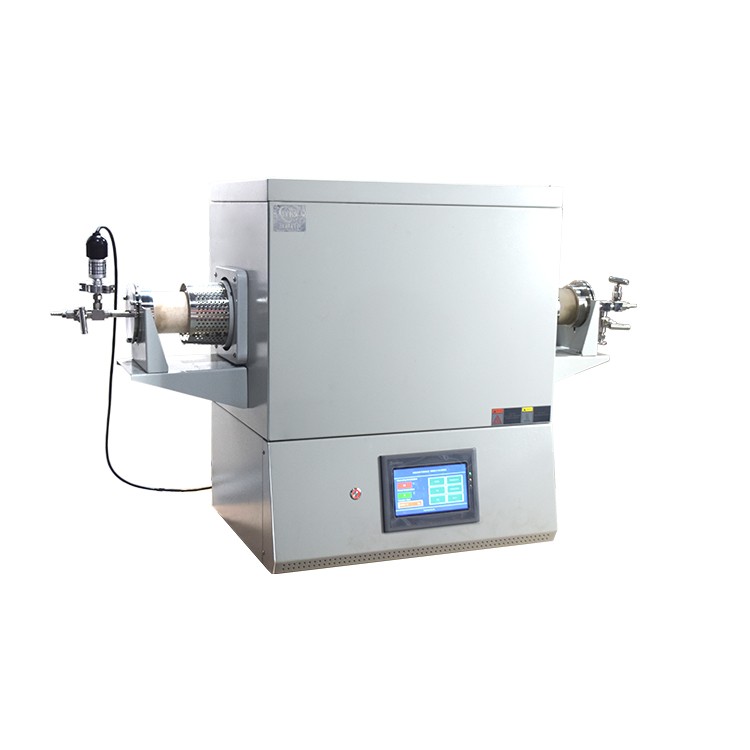

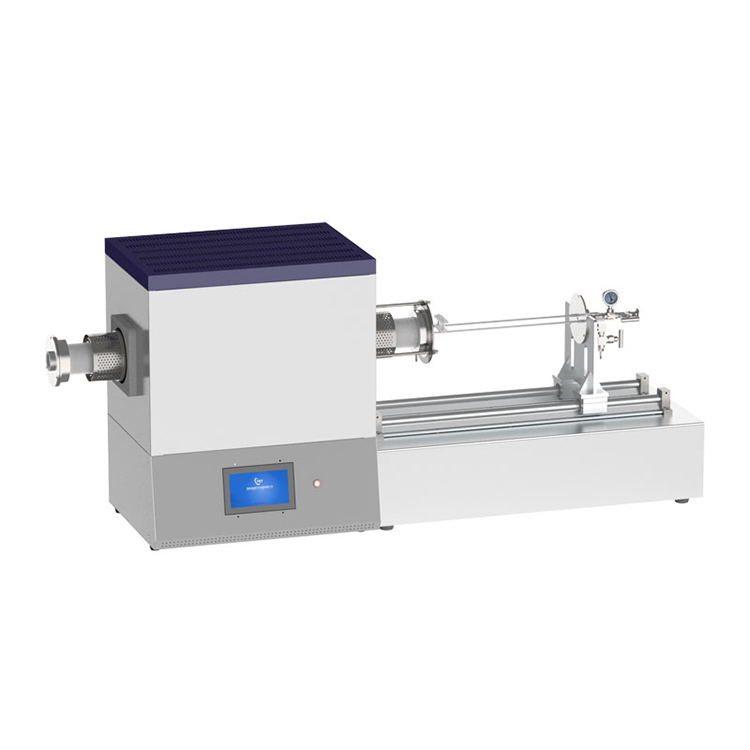

Two temperature zone tube furnace consists of a dual temperature zone tube furnace, a temperature controlled evaporator and a humidity monitor. The combination of the temperature-controlled evaporator and the humidity monitor can continuously produce water vapor that meets the test ratio requirements, that is, by observing the humidity monitor's indication, the rate of water vapor generation can be adjusted by adjusting the heating rate of the temperature-controlled evaporator accordingly. If combined with a three channel float flowmeter, precise control of the gas composition and humidity can be achieved, which is suitable for liquid source and chemical precursor transport in CVD processes.

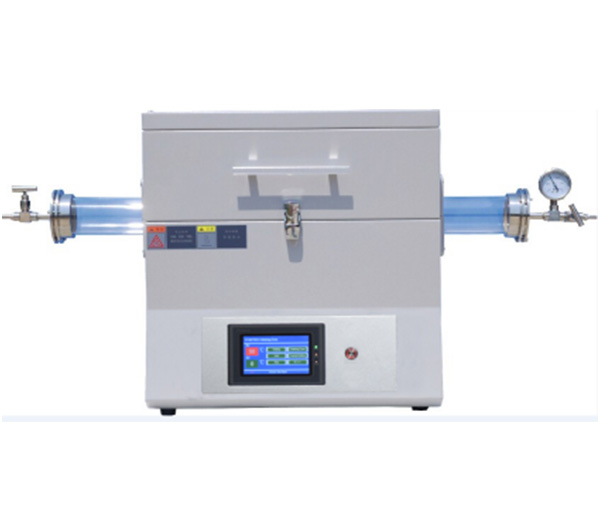

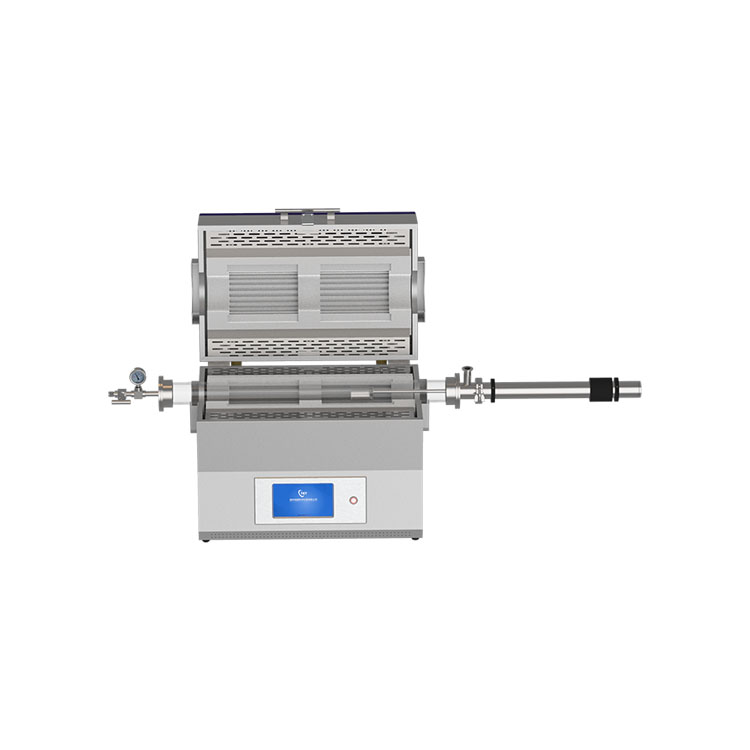

The tube of the tube furnace horizontally passes through the furnace chamber, the heating element is evenly distributed around the circumference, the temperature field is uniform, and the internal and external temperature difference between the furnace tube and the furnace can be controlled at about 3℃. The furnace body is designed with a cushioned upper cover support structure for safe opening during operation.

The combination of the two-temperature zone vacuum tube furnace is mainly suitable for CVD tests and reactions requiring control of reaction humidity.

Two temperature zone tube furnace technical parameters:

Item | Detail |

Two zone tube furnace | Supply voltage | AC110V;60Hz |

Working temperature | ≤1100℃ |

Heating rate | Recommended 10℃/min |

Thermocouple type | B-type thermocouple |

Furnace tube size | φ80(OD)×φ74(ID)×1000(L)mm |

Furnace tube material | High purity quartz |

Sealing flange | Gas and vacuum interface with 1/4 inch |

Heating zone | 200mm+200mm |

Temperature control | 1) PID fully automatic control of heating rate, cooling rate and holding time 2) PID control over temperature protection and short protection 3) Over-temperature protection in the alarm function allows the device to operate unattended 4) Temperature control accuracy is ±1℃(ie the displayed temperature and actual temperature difference) |

Heating element | Electric furnace wire |

Evaporator | Capacity | 300mL |

Heating jacket operating temperature | ≤250℃ |

Features | With precision programmable temperature controller control; There are two SS needle valves and a pressure gauge on the container |

Humidity monitor | Installation method | KF25 adapter connected to the processing tube flange |

Measuring range | 0-100% RH, 1.5% FS accuracy, or -60° to +60°DP |

Measurement accuracy | ±0.3° |

Usage | Adjust the evaporator water temperature and H2 gas flow to achieve the desired humidity level |

Three-channel anti-corrosion float flowmeter | Valve type | Stainless steel needle valve |

Normal pipe condition | shut down |

Gas mode | 3 channels |

Connection size | 1/4" |

Pressure range | -0.1~0.15Mpa |

Tube core material | 304 stainless steel |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.