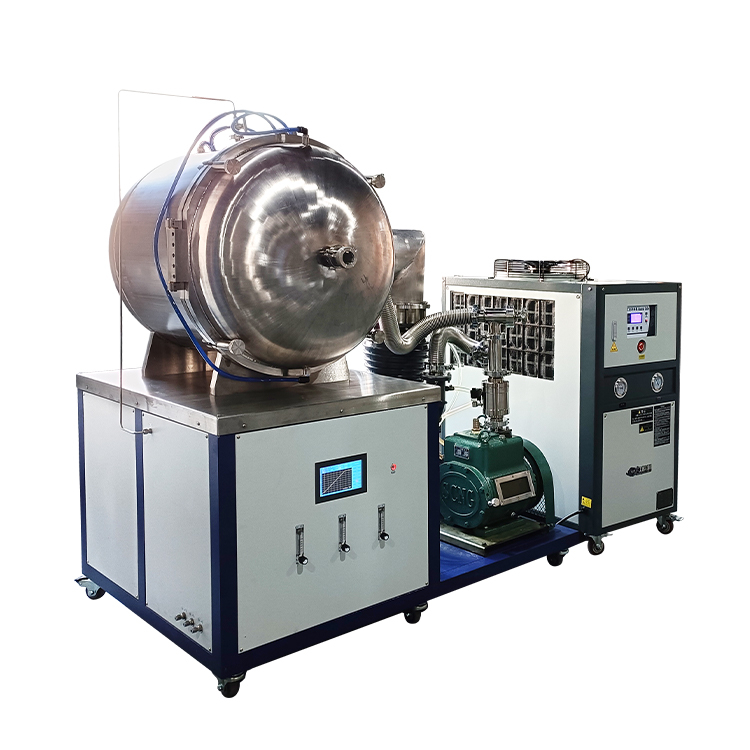

We are honored to introduce to you our product: 1700 degree vacuum furnace. As a professional manufacturer, we are committed to providing high-quality sintering equipment. Our 1700 degree vacuum furnace is an ideal choice for use in the material sintering process.

This vacuum furnace offers outstanding performance and reliability, providing precise control and a stable environment at high temperatures. Its high temperature reaches 1700 degrees, making it suitable for the sintering needs of various materials.

In addition, our 1700 degree vacuum furnace also has the following features:

Advanced vacuum technology: Adopt advanced vacuum system to ensure high purity and oxygen-free environment during the sintering process, thereby improving the quality and purity of materials.

Precise temperature control: Equipped with an advanced temperature control system, it can accurately control and adjust the temperature in the furnace to ensure the stability and consistency of the sintering process.

Safe and reliable: It has multiple safety protection devices, such as over-temperature protection, leakage protection, etc., to ensure the safety of operators and the reliability of equipment.

Easy to operate: The simple and easy-to-understand operating interface and user-friendly design allow operators to easily control and monitor the temperature and vacuum in the furnace.

Our 1700 degree vacuum furnace is widely used in various fields, including metal materials, ceramic materials, powder metallurgy, etc. Whether you are a research institution, laboratory or manufacturing company, our products will provide excellent performance and reliability for your sintering process.

Please contact our sales team for more details about our 1700 degree vacuum furnace. We look forward to working with you and providing you with the best solution.

Main parameter | PN: MG-SV2-4-17TP Max.Temp: 1700℃ (0-1600℃ Continuous working temperature) Suggested heating rate:10℃/min Power supply: AC 220V,single phase Max.power: 4kw Chamber size: 200*150*150mm(W*D*H) |

Furnace structure | 1. Double layers forced air cooling structure,the temperature is less than 60℃. 2. Integrated compact design,stepped split joint structure,personalized furnace door and touch screen operation more convenient and practical. 3. Over-temperature protection,over-current overload protection,bias-temperature protection,burnout thermocouple warning,temperature setting ultra-high protection,temperature program ultrafast protection. 4. Furnace door use integral plane milling,silica gel embedded seal,sealing tightly,furnace door open and close easily. 5. 3 gas channels +Rotameter with mixing gas tank. |

Materials of furnace chamber

| 1. High quality high-purity alumina polycrystalline fiber solidified furnace formed by vacuum suction filtration. 2. Made with Japanese technology. 3. The furnace material has low heat capacity and low heat conductivity, so it has less heat dissipation, good heat preservation and high reflectivity. The temperature field is balanced. 4. The furnace aluminum oxide wire is thin and long, with high temperature resistance and strong resistance to heat expansion and cold contraction. 5. The furnace surface is smooth and clean, and the powder is not easy to fall off. |

Heating element: | Mosi2 heater The amorphous oxide film on the surface of silicon molybdenum rod is dense, which can better protect the silicon molybdenum rod. |

Thermocouple | B type(overheating and couple breaking protection) |

Temperature controlling | Temperature accuracy: ±1℃ Yudian programmed temperature control instrument 1. 30 segment program temperature control intelligent PID regulation. 2. With overtemperature protection and thermocouple breaking protection, the heating circuit of the electric furnace will be cut off automatically in case of overtemperature or thermocouple breaking (when the temperature of the electric furnace exceeds 1720 ℃ or the thermocouple is burnt out, the AC relay on the main circuit will be cut off automatically, the main circuit will be cut off, the ON light on the panel will be off, the OFF light will be on, and the electric furnace will be protected limited). 3. It has the power failure protection function, that is, when the furnace is powered on and started after the power failure, the program starts to rise not from the initial temperature, but from the furnace temperature when the power is cut off. 4. The instrument has the function of temperature self-tuning |

Vacuum system | 1. Vacuum pressure tank 2. Digital display vacuum meter 3. Diffusion (vacuum)pump group |

Vacuum | (in cold state) ≤ 10-3 pa |

Can Insert Gas | All inert gas,mixed gas,nitrogen,carbon dioxide.water vapor,argon gas and oxygen etc. |

Vacuum structure | 1. Double-layer water-cooled Inner stainless steel and external stainless steel shell, welded by professional pressure vessel factory to ensure gas tightness, no trachoma, broken lines and other air leakage points. 2. 3. The door is hinged sideways, the professional pressure bearing supports the door arm, the opening and closing door is easy and convenient, and has the function of adjusting the door up and down. 4. Furnace door seal adopts 20mm thick wire cutting flange, inlay O type silica gel ring, hand wheel lock. |

Warranty | One year limited warranty with lifetime support, excluding heating element,cooling fans,thermocouple and ceramic tube damaged by user. Attention: Any damages caused by the use of corrosive and acidic gases, and any damage from wrong operate and use are not under the coverage of One Year Limited Warranty. |

Package information | Standard wooden box package 1. 1515*1190*1660mm,667kg(Furnace body) 2. 725*560*760mm,146kg(Vacuum pump) 3. 735*605*1510mm,92kg(Electric control cabinet)

|