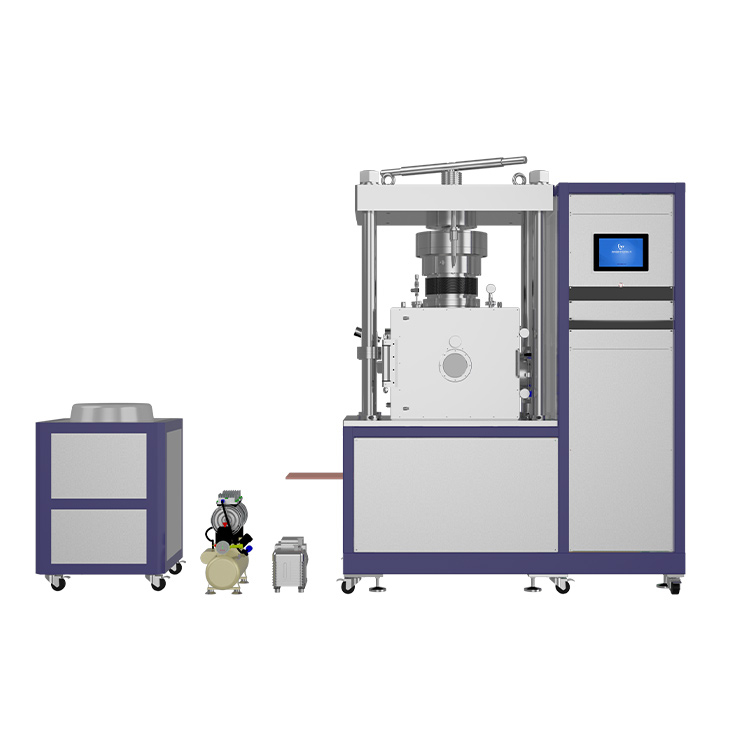

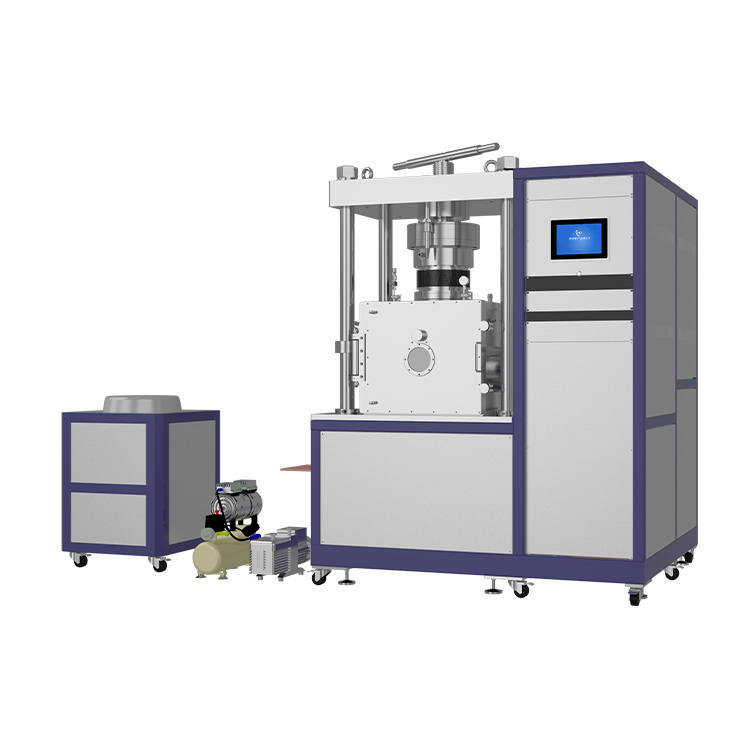

2000℃ 100T spark plasma sintering furnace

Spark plasma sintering furnace is a new technology for rapid powder consolidation. SPS uses high-current pulse power to excite and promote the consolidation and reactive sintering process of materials. Compared with traditional technology, SPS can adjust the density values of various conductors, non-conductors and composite materials to any required value during the processing process. SPS shortens the experimental time and energy consumption to the greatest extent, while perfectly maintaining the micro-nano structure of the material. Therefore, since its birth, it has quickly become an important tool in many fields such as scientific research, new material research and development, and industrial production.

Spark plasma sintering furnace is a new technology for rapid powder consolidation. SPS uses high-current pulse power to excite and promote the consolidation and reactive sintering process of materials. Compared with traditional technology, SPS can adjust the density values of various conductors, non-conductors and composite materials to any required value during the processing process. SPS shortens the experimental time and energy consumption to the greatest extent, while perfectly maintaining the micro-nano structure of the material. Therefore, since its birth, it has quickly become an important tool in many fields such as scientific research, new material research and development, and industrial production.

The discharge plasma sintering system has a maximum temperature of up to 2000°C. It can be used for material annealing, material hot pressing bonding, surface treatment and synthesis, etc. The processed samples can be metals, ceramics, nanomaterials, amorphous materials, etc. This equipment is particularly suitable for the study of solid electrolytes and thermoelectric materials

Technical Parameters:

product name | 2000℃Spark plasma sintering furnace(SPS) |

Product number | CY-SPS500-80KW-100T |

structure | Stainless steel vacuum chamber Hot pressing system DC pulse power supply Vacuum system Hot pressure control system |

Power | 80KW |

Input power | AC380V 50Hz three-phase |

Output current | DC0-10000A (digital control) |

The output voltage | DC0-10V (digital control) |

Pulse frequency | 5 - 255 ms (adjustable) 2 - 1000 Hz (adjustable) |

maximum temperature | 1200ºC (Type K thermocouple) 2000ºC (infrared temperature measurement) The equipment is equipped with these two types of thermocouples |

Temperature Control System | Adopt precision Eurotherm temperature control instrument According to the fastest heating rate, the over-temperature is less than 3℃ Temperature control accuracy: 0.1℃ |

Hydraulic pressure | Manual operation pressurization Maximum pressure: 100T Digital display pressure gauge with overpressure alarm |

Mold | Equipped with hot isostatic pressing graphite mold (made in Japan) Mold core diameter: 12 - 50 mm (can be customized according to customer requirements) The maximum bearable pressure is 50MPa, and the maximum bearable pressure depends on the diameter of the mold core. 1/2 inch mold core, maximum pressure 0.5T 1 inch mold core, maximum pressure 3T |

sintering zone | 100mm |

vacuum chamber | Stainless steel chamber Double-layer cavity, cooling water needs to be introduced |

Vacuum degree | 10 Pa (7.5 x 10^-2 torr) (using mechanical pump, equipped with two-stage rotary vane vacuum pump) 1 Pa (10x10-4 torr) (using molecular pump system, can be selected at our company) |

Maximum heating rate | 300℃/min |

Circulating water cooler | The equipment is equipped with a circulating water cooler with a flow rate of 58L/min. |

Standard accessories | Special SPS hot pressing mold |

size | Power supply size:760 L X 460 W X 1820 H, mm Furnace size:1350 L X1575W X2000 H, mm |

Quality Certification | CE certification |